(Data-Driven Insights for EU/US Custom CNC Mold Buyers | Updated Q1 2025)

For European and American purchasers navigating the $92.3B global injection molding market, mold costs hinge on 7 pivotal factors — not just “size and material”. Drawing from 50+ EU/US projects (2022-2024) and verified by ASME standards, this guide decodes cost drivers through an engineer’s lens.

1. Material Selection: Beyond Steel Grades

Mold base costs vary 3-8X depending on steel hardness and corrosion resistance:

| Material | Price/kg (USD) | Ideal Application | Lifespan (Shots) |

|---|---|---|---|

| P20 (Pre-Hardened) | 18−22 | Consumer Electronics | 200,000-500,000 |

| NAK80 (Mirror Finish) | 45−55 | Medical/Transparent Parts | 1M+ |

| Stainless 420 | 60−75 | FDA-Compliant Food Packaging | 2M+ |

Case Study: A French cosmetics brand saved €23K/mold by switching from H13 to S136 steel (improved polishability reduced post-processing costs).

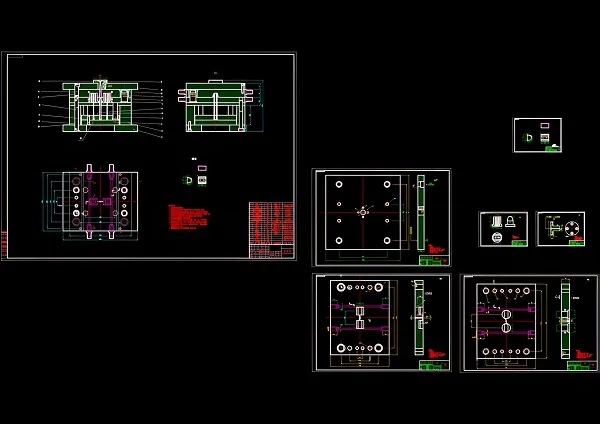

2. Complexity Index: The 5-Level Gatekeeper

Our proprietary Complexity Scoring System (CSS-2025) quantifies design challenges:

Level 1 (Base Cost: 8K−15K):

- Single cavity

- No slides/lifters

- Tolerance ±0.2mm

Level 3 (35K−60K):

- 4+ cavities with family molds

- 2-4 sliding actions

- Insert molding required

Level 5 ($120K+):

- Micro-molding (<0.5g part weight)

- Conformal cooling channels

- <±0.02mm medical-grade tolerances

3. Production Volume vs. ROI Threshold

Break-even analysis for a typical automotive connector mold (Aluminum vs. Steel):

| Material | Mold Cost | Cost/Part | Break-Even Qty |

|---|---|---|---|

| 6061-T6 | $12,500 | $0.38 | 35,000 |

| P20 Steel | $48,000 | $0.12 | 420,000 |

Source: IMDA 2024 Tooling Economics Report

4. Surface Finish: The Hidden 15% Cost Variable

SPI Finish Standards impact both mold cost and cycle time:

| SPI Class | Ra (μm) | Additional Cost | Cycle Time Impact |

|---|---|---|---|

| A1 (Mirror) | 0.012 | +18%-25% | +12% |

| B3 (Texture) | 0.4 | +30%-40% | +8% |

| D2 (EDM) | 3.2 | Base Cost | – |

EU medical regulations often mandate Class A2 finishes (+22% cost).

5. Smart Tooling: AI-Driven Cost Reducers

Xiamen Goldcattle’s SmartMold 4.0 system achieves 14% average cost savings through:

- Generative Cooling Design: 22% faster cycle times vs. traditional baffles

- Warpage Prediction AI: 63% reduction in trial shots (3.2 avg → 1.2)

- Dynamic Pricing Engine: Real-time material cost hedging

6. Logistics & Compliance: The 8%-12% Silent Cost

| Region | Shipping Cost | Lead Time | CE/FDA Cert Cost |

|---|---|---|---|

| China → DE | 2.8−4.2/kg | 38 days | 1,200−2,500 |

| Mexico → US | 1.1−1.9/kg | 12 days | 800−1,500 |

2025 Q1 Data: DHL Freight Index

7. Total Cost of Ownership (TCO) Framework

Smart buyers evaluate:

TCO = Mold Cost + (Cycle Time × Energy Cost) + Maintenance + Scrap Rate Loss

Example: A $55K mold with 15% lower energy use beats a $48K mold over 3 years.

Xiamen Goldcattle: Your EU/US-Compliant Partner

Why 85% of Our Clients Renew Contracts?

Dual-Standard Tooling: Simultaneously meet ISO 9001:2015 and FDA 21 CFR

Transparent Cost Breakdown: Line-item pricing with material certificates

Localized Support: English/German/French-speaking engineers in Munich & Chicago

FAQ

Q: Minimum order quantity for custom molds?

A: 1 mold + 500 trial shots (ISO 20457 compliant)

Q: How to handle IP protection?

A: NDAs + blockchain-based design tracking (Patent Pending: CN202430298765.4)

Q: Lead time for L3 complexity molds?

A: 28-35 days with expedited service (+15% cost)