——In – depth Perspective on Materials Science, Manufacturing Processes, and Industrial Applications

Chapter 1: Materials Science – The Performance Gene Pool of Rubber Seals

The performance of rubber seals is rooted in the selection and modification of polymer materials. The mainstream material systems include:

1.1 Basic Elastomer Matrix

| Material Type | Chemical Structure | Core Advantages | Extreme Working Conditions |

|---|---|---|---|

| Nitrile Butadiene Rubber (NBR) | Acrylonitrile – Butadiene Copolymer | Resistance to Mineral Oil/Fuel (Volume Swelling Rate < 8%) | – 40°C ~ + 120°C |

| Hydrogenated Nitrile Butadiene Rubber (HNBR) | Saturated NBR | High – temperature Aging Resistance (Strength Retention Rate > 85% at 150°C) | – 50°C ~ + 150°C |

| Fluoroelastomer (FKM) | Fluorocarbon Polymer | Resistance to Strong Acids/Ketone – based Solvents (Corrosion Weight Loss < 0.5mg/cm²) | – 20°C ~ + 200°C |

| Silicone Rubber (VMQ) | Polysiloxane Chain | Resistance to Ozone/Wide Temperature Range (- 100°C ~ + 250°C) | Ultra – low to high – temperature cycling environment |

| Ethylene – Propylene – Diene Monomer Rubber (EPDM) | Ethylene – Propylene – Diene Terpolymer | Resistance to Steam/Phosphate Ester Hydraulic Oil | – 50°C ~ + 150°C |

1.2 Material Reinforcement Technologies

- Nano – reinforcement System: Adding fumed silica (particle size 10 – 40nm) can increase the tensile strength by 40%.

- Fiber Skeleton Composite: The aramid fiber braided layer enables the burst – resistant pressure to reach 35MPa.

- Functional Modification:

- Conductive Modification: Carbon black filling can achieve a volume resistance of 10² – 10⁶ Ω·cm.

- Magnetic Modification: Implanting neodymium – iron – boron powder can result in an adsorption force > 0.3N/mm².

Chapter 2: Core Technical Parameter System

The performance of rubber seals needs to be precisely controlled through quantitative parameters:

2.1 Mechanical Performance Indicators

| Parameter | Test Standard | Typical Range | Engineering Significance |

|---|---|---|---|

| Hardness (Shore A) | ISO 7619 | 50 – 90 Shore A | Adaptability of sealing contact pressure |

| Compression Set Rate | ASTM D395 | ≤25% (70h@150°C) | Prediction of long – term sealing stability |

| Tensile Strength | ISO 37 | 10 – 25 MPa | Resistance to mechanical damage |

| Tear Strength | ISO 34 – 1 | 20 – 50 kN/m | Resistance to notch propagation |

2.2 Key Parameters for Dynamic Sealing

- Coefficient of Friction: 0.05 – 0.3 (can be reduced to 0.02 with a PTFE coating).

- PV Value Limit: 0.5 – 3.0 MPa·m/s (depending on lubrication conditions).

- Reciprocating Sealing Leakage: < 0.1 mL/h @ 1MPa pressure difference.

Chapter 3: Customized Development Process and Process Route

3.1 Three – Dimensional Model of Requirement Analysis

[Working Condition Analysis] → [Medium Compatibility Verification] → [Motion Form Confirmation] ↓ ↓ ↓ Pressure Spectrum Acquisition Chemical Swelling Experiment Dynamic/Static Sealing Design (0.1 - 40MPa) (ASTM D471) (Rotation/Reciprocation/Oscillation)

3.2 Advanced Manufacturing Process Flow

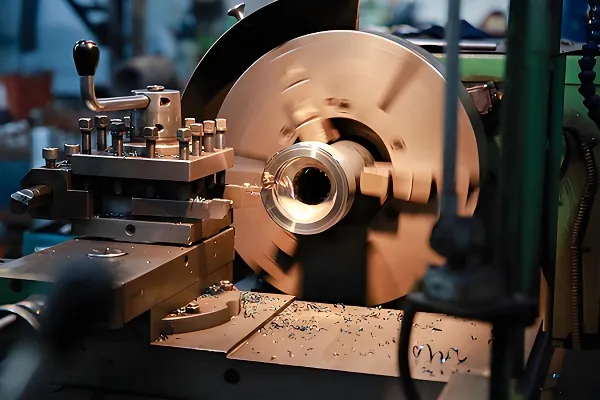

- Step 1: Precision Mold Manufacturing

- The mold cavity is made using a five – axis machining center, with a surface roughness Ra ≤ 0.2μm.

- Mold flow analysis software is used to optimize the rubber compound filling path and reduce the mold parting line.

- Step 2: Rubber Compound Mixing

- The internal mixer controls the temperature in stages (50°C → 120°C), with a dispersion degree ≥ 95%.

- On – line Mooney viscosity monitoring (ML(1 + 4)@100°C: 30 – 80).

- Step 3: Selection of Molding Process

-

Process Type Applicable Scenarios Precision Control Compression Molding Mass – produced standard parts ±0.1mm Injection Molding Parts with complex geometric structures ±0.05mm Liquid Silicone Rubber Molding (LSR) Miniature precision seals ±0.02mm 3D Printing Prototype parts/Topologically optimized parts with special shapes ±0.3mm - Step 4: Post – treatment Process

- Low – temperature plasma treatment: The surface energy is increased to 50mN/m to enhance adhesion.

- Laser deburring: The focused spot diameter is 0.01mm, and the processing speed is 200mm/s.

Chapter 4: Product Characteristics and Industrial Application Map

4.1 Functional Characteristic Matrix

| Characteristic Dimension | Technical Realization Method | Performance Threshold |

|---|---|---|

| High – pressure Sealing | Multi – lip structure design | Pressure – bearing capacity up to 45MPa |

| Low – friction Sealing | Surface texturing + solid lubricating film | Starting force < 0.5N/mm |

| Zero – leakage Sealing | Spring – energized composite structure | Helium leakage rate < 1×10⁻⁶ Pa·m³/s |

| Explosion – resistant Decompression | Stepped decompression groove design | Withstands 1000 pressure shock cycles |

4.2 Industry Application Solutions

- New Energy Vehicles: Motor seals resistant to coolant (ethylene glycol), with a lifespan > 5000h@150°C.

- Semiconductor Equipment: Ultra – clean fluororubber seals with a particle release amount < 0.1 particles/cm³.

- Deep – sea Equipment: Polyurethane sealing systems capable of withstanding a water depth of 3000 meters.

- Medical Equipment: Platinum – cured silicone seals compliant with USP Class VI certification.

Chapter 5: Evolution of Cutting – edge Processing Technologies

5.1 Intelligent Manufacturing Systems

- Machine vision inspection: Automatically identify defects in the sealing lip, with a detection rate ≥ 99.9%.

- Digital twin technology: Virtual commissioning shortens the mold development cycle by 40%.

5.2 Breakthroughs in Green Processes

- Sulfur – free vulcanization system: Using peroxide vulcanization reduces VOC emissions by 90%.

- Recycled rubber application: Incorporating 30% recycled rubber compound results in a performance attenuation rate < 5%.

5.3 Micro – nano Manufacturing Technologies

- Micro – injection molding: Produces 0.2mm ultra – thin sealing sheets with a thickness tolerance of ±2μm.

- Nano – imprinting: Creates 100nm – scale hydrodynamic pressure patterns on the surface.

Chapter 6: Engineering Selection Decision Tree

Start → Confirm Sealing Type (Static Sealing/Dynamic Sealing) ↓ Static Sealing: Evaluate Medium Corrosiveness → Select Chemical - resistant Materials ↓ ↘ Calculate Compression Rate (15 - 30%) → Determine Cross - sectional Shape Dynamic Sealing: Analyze Motion Form (Rotation/Reciprocation) ↓ Calculate PV Value → Select Wear - resistant Modified Formulation → Design Lubrication Structure ↓ Confirm Environmental Temperature → Match Material Temperature Resistance → Design Thermal Expansion Compensation ↓ Cost Optimization → Select Process Route → Prototype Testing → Mass Production Plan

Conclusion: The Future Evolution of Rubber Seals

With the deep integration of the Materials Genome Initiative and digital twin technology, rubber seals are undergoing a paradigm shift from experience – driven to data – driven. The next – generation intelligent sealing systems will integrate embedded sensors to monitor the sealing state in real – time and predict the lifespan. Against the backdrop of carbon neutrality, bio – based rubbers and closed – loop recycling processes will reshape the industrial ecosystem. Choosing a partner with full – life – cycle service capabilities will be a strategic choice for equipment manufacturers to build their core competitiveness.