Custom CNC Kitchen Hardware Fittings is a service that utilizes Computer Numerical Control (CNC) technology to accurately machine and manufacture hardware fittings for kitchens according to customers’ needs.CNC machining technology has significant advantages in customized production of kitchen hardware fittings due to its high precision, high efficiency and high flexibility. The following is a detailed introduction about customized CNC kitchen hardware accessories:

1. Advantages of customized CNC kitchen hardware accessories

High precision: CNC machining technology can realize micron-level machining precision, which ensures that the size and shape of the fittings are in full compliance with the design requirements and improves the performance and life of the kitchen hardware fittings.

Personalized customization: according to the customer’s specific needs and kitchen decoration style, provide personalized hardware fittings design solutions, such as color, material, shape, etc., to make the kitchen more beautiful and practical.

Efficient production: CNC machining equipment with a high degree of automation can greatly improve production efficiency and shorten the production cycle to meet the customer’s rapid delivery needs.

Variety of materials: support a variety of materials processing, such as stainless steel, aluminum alloy, brass, etc., customers can choose the right material according to the kitchen environment and personal preferences.

2.The process of customized CNC kitchen hardware accessories

Demand communication: customers and service providers to carry out preliminary communication, clear specific needs for kitchen hardware accessories, including quantity, size, material, design requirements.

Program design: the service provider according to customer demand for program design, including drawing, material selection, process development, and so on, and confirm with the customer.

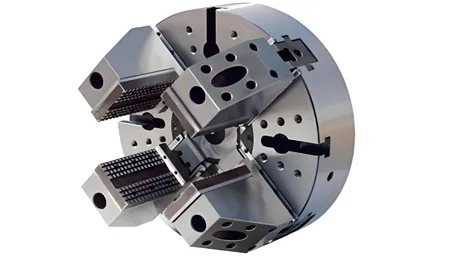

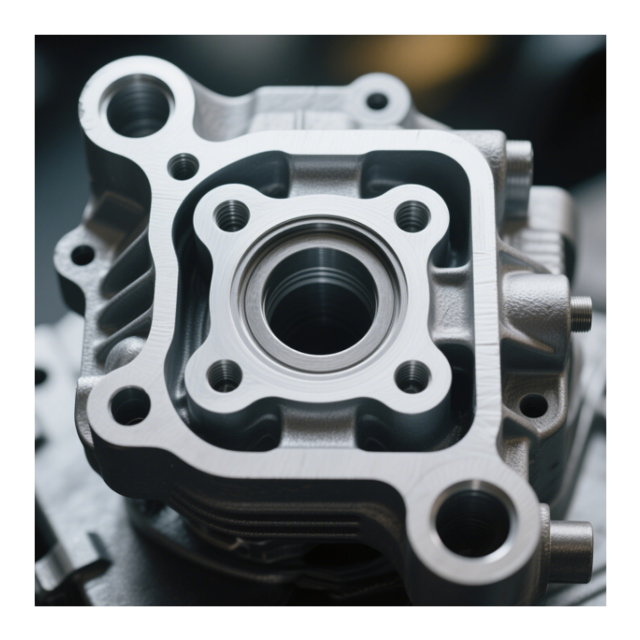

CNC machining: Utilizing CNC machining equipment to carry out precision machining, including cutting, drilling, milling, grinding and other processes, to ensure the accuracy and quality of the fittings.

Surface treatment: We carry out surface treatment on the finished parts, such as polishing, spraying, plating, etc., to improve the aesthetics and corrosion resistance of the parts.

Quality Inspection: Strict quality inspection is carried out on the finished fittings to ensure that they meet customer requirements and industry standards.

Delivery and installation: Deliver qualified fittings to customers and provide necessary installation guidance and after-sales service.

3. Material Performance

Strength and hardness: Kitchen hardware fittings need to withstand a certain force, such as the switching of cabinet door panels, drawer sliding, etc., so the material should have high strength and hardness. Stainless steel, aluminum alloy and other metal materials are common choices, they have high strength and hardness to meet the needs of kitchen hardware.

Corrosion resistance: the kitchen environment is relatively humid, and may come into contact with a variety of food and cleaning agents, so the material should have good corrosion resistance to prevent rust and corrosion. Stainless steel has become the material of choice for kitchen hardware because of its excellent corrosion resistance.

Wear resistance: Kitchen hardware fittings are subject to frequent contact and friction during use, so the material should have good wear resistance to ensure the service life of the fittings.

| Material Name | Density (g/cm³) | Hardness (HBW/HRC) | Corrosion Resistance | Machinability | Sample CNC Machining Parameters |

| Stainless Steel | 7.93 | Varies by alloy, e.g., 304 SS ≈ 180HBW | Excellent | Good, but avoid overheating | Spindle Speed: 2000-3000 rpm

Feed Rate: 50-100 mm/min |

| Aluminum Alloy | 2.7 | Varies by alloy, e.g., 6061 Alloy ≈ 60-95HBW | Moderate | Excellent, easy to cut | Spindle Speed: 4000-6000 rpm

Feed Rate: 100-200 mm/min |

| Brass | 8.4-8.9 | Lower, ≈35-55HBW | Good | Good, but prone to tool sticking | Spindle Speed: 1500-2500 rpm

Feed Rate: 60-100 mm/min |

| Titanium Alloy | 4.5 | High, ≈30-40HRC | Excellent | Poor, requires high cutting speeds and low feed rates | Spindle Speed: 800-1500 rpm

Feed Rate: 20-50 mm/min |

| Superalloy | Varies by alloy, generally high | High, varies by alloy | Excellent | Poor, requires special tooling and cooling | Spindle Speed: Lower, e.g., 600-1000 rpm

Feed Rate: Very low, e.g., 10-30 mm/min |

4.Customized CNC Kitchen Hardware: Xiamen Goldcattle

Xiamen Goldcattle, as a company specializing in hardware fittings and precision manufacturing, has also demonstrated its strength and professionalism in the field of customized CNC kitchen hardware fittings. The following is a corporate profile of the company:

Business Scope and Product Characteristics

Main business: Xiamen Goldcattle specializes in R&D and manufacturing of high-precision injection-molded parts, high-precision plastic parts and metal parts, providing customers with all-around solutions including mold design and manufacturing, mass production and assembly of parts.

Product range: The company’s products include, but are not limited to, kitchen hardware fittings such as hinges, slides, handles, etc., which may be precision machined using CNC (Computer Numerical Control) technology to ensure high quality and accurate dimensional control.

Customized Service: As a factory providing OEM and ODM services, Xiamen Goldcattle is able to customize and develop products according to customers’ specific needs to meet the diversified demands of the kitchen hardware fittings market.

Technology and Strength

R&D team: We have an experienced team of industrial designers and engineers who are good at mold design, manufacturing and CNC programming, which provides solid technical support for product innovation and high quality production.

Production equipment: We adopt advanced CNC processing equipment and production technology to ensure the precision and consistency of our products.

Quality control: Adhering to the principles of “high quality, high efficiency, integrity and service”, and with the goal of “sustainable operation, customer first”, the company strictly controls product quality, which has won the trust and praise of customers.

Markets and Customers

Main Markets: Xiamen Goldcattle’s products not only sell well in the domestic market, but also overseas, including South Asia, South America, Eastern Europe, Southeast Asia, Oceania, the Middle East, Africa, East Asia, Western Europe, Central America, Northern and Southern Europe and other regions.

Customer base: The company’s customers are all over the world, including retailers, agents and end users from different countries and regions.

Customized Kitchen Hardware Fittings FAQ

Question 1: What materials should I choose for kitchen hardware?

Answer: The choice of material for kitchen hardware fittings is crucial as it directly affects the durability, aesthetics and safety of the fittings. Common materials include stainless steel, aluminum alloy, brass and special alloys such as titanium alloy or high temperature alloy. Stainless steel is preferred for its excellent corrosion resistance and ease of processing, especially 304 stainless steel which performs better in wet environments. Aluminum alloys are lightweight and high strength, suitable for fittings that require some load-bearing capacity. Brass is beautiful, but relatively weak corrosion resistance, requiring regular maintenance. Special alloys such as titanium and high-temperature alloys are suitable for special environments or high-end customization needs.

Question 2: What are the common hardware fittings in the kitchen?

Answer: Common hardware fittings in the kitchen mainly include the following:

Hinges (hinges): used to connect the cabinet and cabinet door, according to the material and function can be divided into cold rolled steel hinges, stainless steel hinges and damping hinges. Damping hinges have a buffer effect, can reduce the impact of the door closed.

Slide: used for drawer opening and closing, divided into side mounted slide and bottom slide. Bottom slides are installed at the bottom of the drawer, which is more beautiful and has a strong load-bearing capacity.

Gas strut (gas spring, support rod): mainly used for upturned doors or downturned doors and other cabinet doors, with the role of support, to avoid opening and closing the door when touching the head. Divided into ordinary stop gas support and random stop gas support, the latter is more convenient to use.

Handle: cabinet handles from the installation can be divided into external and concealed installation, from the material can be divided into copper, aluminum, stainless steel, plastic and so on. Selection should be considered with the overall style of the cabinet coordination.

Basket: used to store dishes and other tableware, improve the utilization of space inside the cabinet. Basket material is mostly stainless steel, durable and corrosion-resistant.

Lifting rack: used for hanging cabinets and other high cabinets, easy access.