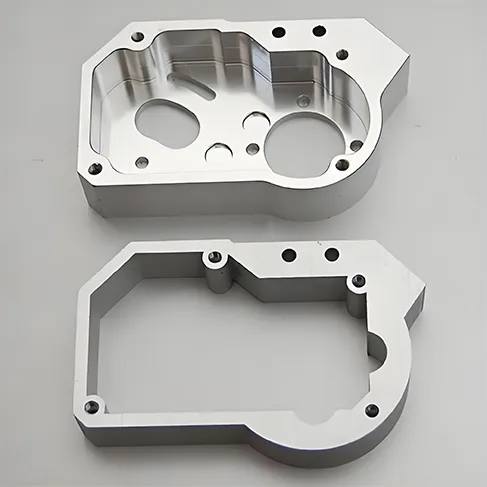

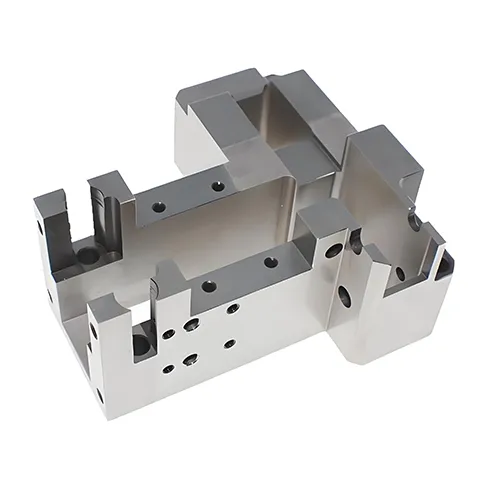

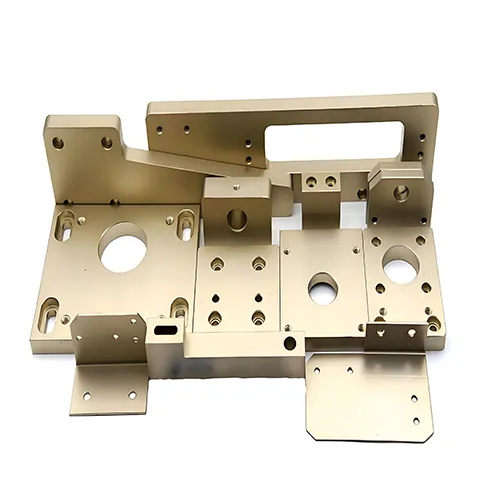

Precision CNC processing pipe fittings, stainless steel / aluminum alloy professional customization

Place of Origin : XiaMen, China

Brand : JSD

Model : CNC-42

MOQ : 1 pc

Cost Control : Most efficient production process design

Quality control : 100% inspection of critical dimensions

Management : Skilled workers and experienced staff

Surface treatment : sandblasted, anodized, powder coated

Quality control : 100% guarantee

Application : Industrial equipment

Service : One-stop service

Description

Product Overview

We provide high-precision CNC machined pipe fittings made of high-quality stainless steel and aluminum alloy materials, through professional customization process, to meet the needs of various industrial and commercial pipe systems. These fittings not only have excellent corrosion resistance and mechanical properties, but also have precise dimensions and convenient installation, suitable for a variety of fluid transmission and environments.

Product Features

1. Precision machining: The use of the most advanced CNC machining technology ensures that the size and shape of each pipe fitting meet extremely high precision standards.

2. Material selection: Stainless steel and aluminum alloy are available to meet different environmental and performance requirements.

3. Customization service: Tailor-made pipe fittings are provided according to the specific needs of customers, including special sizes, shapes and connection methods.

4. Corrosion resistance: Both stainless steel and aluminum alloy materials have good corrosion resistance and are suitable for a variety of corrosive environments.

5. High strength: The material has excellent mechanical properties and can withstand use under high pressure and high temperature conditions.

6. Easy installation: The fittings are designed with ease of installation in mind, reducing on-site installation time and labor costs.

7. Widely used: Applicable to many industries such as petroleum, chemical, food processing, pharmaceutical, water treatment, etc.

Customization process

1. Demand communication: Communicate with customers in detail to clarify the size, material, performance and other requirements of accessories.

2. Design confirmation: Provide design drawings for customer confirmation to ensure that all details are accurate.

3. Sample production: Make samples for customer testing and confirmation.

4. Mass production: After sample confirmation, mass production is carried out.

5. Quality inspection: Strict quality control process to ensure that each accessory meets the standards.

6. Packaging and delivery: Safe packaging and timely delivery.

Customer testimonials

☆☆☆☆☆

“This CNC-machined pipe fitting is of very good quality, precise in size, and easy to install, which greatly improves the overall quality of our project.” — Manager Li, Mechanical Engineering Company

☆☆☆☆☆

“The customized aluminum alloy pipe fittings fully meet our technical requirements, and have excellent corrosion resistance and mechanical strength.” — Engineer Zhang, Chemical Equipment Supplier

Contact us now to get your exclusive customized service for precision CNC-machined pipe fittings!