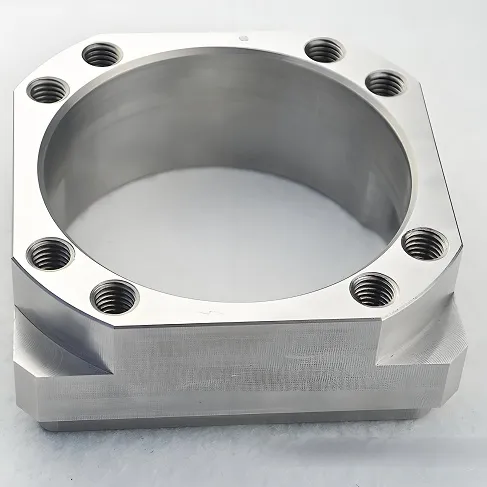

Custom CNC stainless steel machining parts

Place of Origin : XiaMen, China

Brand Name : JSD

Model Number : CNC-13

Type : Broaching, DRILLING, Etching / Chemical Machining, Laser Machining, Milling, Other Machining Services, Rapid Prototyping, Turning, Wire EDM

Micro Machining or Not : Micro Machining

Material : Stainless steel

Service : Customized OEM

Finish : Oxidation Etc

Size : Technical Drawing

Tolerance : +/-0.05mm

Process : Cnc Machining+deburrs

OEM/ODM : OEM ODM CNC Milling Turning Machining Service

Drawing Format : 2D/(PDF/CAD)3D(IGES/STEP)

Quality control : 100% Inspection Berore Shipment

Materials Avaliable : Stainless steel/Aluminum/Brass

Description

【Product Description】

Designed for harsh environments, our corrosion-resistant CNC stainless steel parts are ideal for those seeking high performance and reliability. Crafted from high quality stainless steel, these parts are precision CNC machined to ensure superior performance in even the most challenging conditions.

【Product Features】

1. CORROSION RESISTANCE: The specially treated stainless steel material effectively resists oxidation and corrosion and is suitable for environments such as salt water and chemical corrosion.

2. High Performance: Precise CNC machining technology ensures the stability and reliability of parts under extreme conditions.

3. Durability: After rigorous testing, our stainless steel parts have an extra-long service life, reducing maintenance and replacement frequency.

4. Precision machining: Strict tolerance control to meet the precision requirements of complex designs.

5. Widely used: applicable to many industries such as petroleum, chemical, marine engineering, food processing, etc.

Why choose our corrosion resistant CNC stainless steel parts?

1. Specialized materials: we only use the highest quality stainless steel materials to ensure the corrosion resistance and mechanical strength of the parts.

2. ADVANCED TECHNOLOGY: We use the latest CNC machining technology to ensure the precision and consistency of the parts.

3. Quality Assurance: Each part undergoes strict quality testing to ensure that it leaves the factory without defects.

4. Customized service: provide personalized design and production solutions according to customers’ specific needs.

【Applications】

● Marine engineering: for structural parts of ships and offshore platforms, seawater corrosion resistant.

● Chemical industry: applied to reactor, pipeline connectors, etc., resistant to chemical medium corrosion.

● Food processing: in line with food safety standards, used for food processing machinery components.

【Conclusion】

Choosing our corrosion resistant CNC stainless steel parts for harsh environments is choosing high performance and long lasting durability. Let us provide the most solid support for your equipment to ensure stable operation even under extreme conditions.