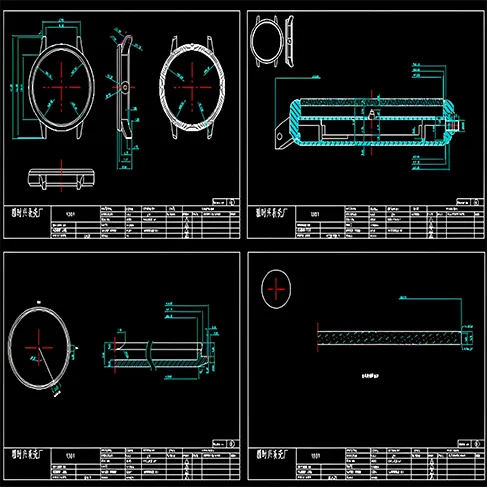

Custom Vintage Mechanical Watch CNC Stainless Steel/Brass Watch Case

Place of Origin : XiaMen, China

Type : Broaching, DRILLING, Etching / Chemical Machining, Laser Machining, Milling, Other Machining Services, Turning, Wire EDM, Rapid Prototyping

Micro Machining or Not : Micro Machining

Model : CNC-21

Brand Name : JSD

Keyword : CNC Watch Case Machining Manufacturer

Product name : CNC Watch Case Machining Manufacturer

Process : Hobbing, Milling, Shaping, Broaching, Shaving

Surface treatment : Anodized, Electrical Plating, Polish

MOQ : Small Orders Accepted

Tolerance : 0.005mm

Lead time : Determined by your quantity and detailed requirements

Application : CNC Watch Case Machining Manufacturer

Dimension : Accept Customization

Package : Standard Export Carton With Pallet Or As Per Customes’requirement

Description

Product Overview

We specialize in providing high-quality, high-precision precision stainless steel/brass CNC chassis customization services. We use advanced CNC (computer numerical control) processing technology, combined with high-quality stainless steel and brass materials, to create a unique chassis solution for you. Whether it is industrial applications, electronic equipment housings, or personalized artworks, we can meet your customization needs.

Key Features

High-precision processing: Using high-precision CNC machine tools to ensure that every detail meets the design requirements, and the tolerance is controlled at the micron level.

High-quality materials: Select high-quality stainless steel and brass, which are corrosion-resistant and high-strength, suitable for various harsh environments.

Personalized customization: From design to production, one-to-one service throughout the process, customized according to your specific needs.

Quick response: With a professional design team and production team to ensure fast response and efficient delivery.

Application areas

Industrial automation: Customize industrial-grade chassis to meet the protection needs of various automation equipment.

Electronic equipment: Provide sturdy and durable housings for electronic equipment such as servers, routers, switches, etc.

Artwork customization: Combine CNC processing technology with art to create unique metal artworks.

Customer Cases

Case 1: Customized a batch of server chassis with high protection level for a well-known technology company, which effectively improved the stability and safety of equipment operation.

Case 2: Customized special chassis for an industrial automation equipment manufacturer to meet the use requirements in extreme working environments.

Service Process

Demand Communication: Communicate with customers in detail about the requirements, including size, material, surface treatment, etc.

Design Confirmation: Provide a preliminary design plan according to customer needs, and enter the production stage after confirmation.

Production and Processing: Use high-precision CNC machine tools for processing to ensure product quality.

Quality Inspection: Strictly control every production link to ensure that the product meets the design requirements.

Packaging and Delivery: Use professional packaging to ensure that the product is not damaged during transportation and is shipped in time.

Contact Us

If you have any questions or needs about the precision stainless steel/brass CNC chassis customization service, please feel free to contact us. We will wholeheartedly provide you with the best service and solutions.