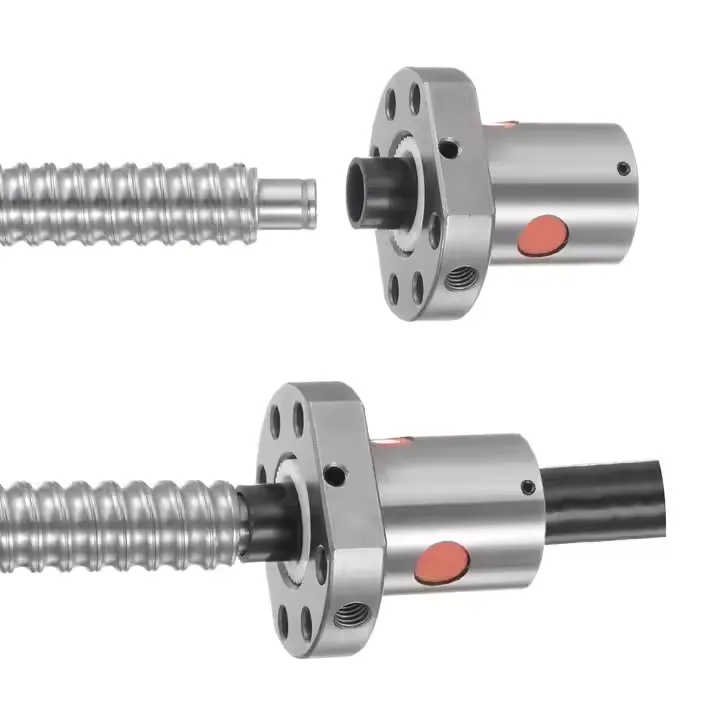

Custom Ball Screw Nuts SFU1204 Single Nut for 1204 Nut Housing

Place of Origin : Fujian, China

Type : Milling, Turning

Micro Machining or Not : Micro Machining

Model Number : CMP-A11

Brand Name : JSD

Product name : Customized Ball Screw Nut

Material : Customers’ Requirement

Surface treatment : Painting\Powder Coating\Plating\Polishing

Service : Customized OEM

Drawing Format : 2D/(PDF/CAD/DWG/DXF)3D(IGES/STEP/VDA)

Equipment : 3/4/5 Axis CNC Machining Center

Keyword : Cnc Machining Parts Cnc Machining Service

OEM/ODM : OEM ODM Non-standard Processing

Certification : ISO9001

Tolerance : 0.01- +/-0.005mm

Description

1. Products

Welcome to our store, you are browsing our carefully crafted customized ball screw nut products. As a core component in the transmission system, ball screw nut is widely used in automation equipment, CNC machine tools, precision measuring instruments and other fields due to its high accuracy, high efficiency and long life. Our customized Ball Screw Nuts are designed to meet your individual needs for specific size, load and accuracy requirements, ensuring the optimal performance of your equipment.

2. Product Specifications

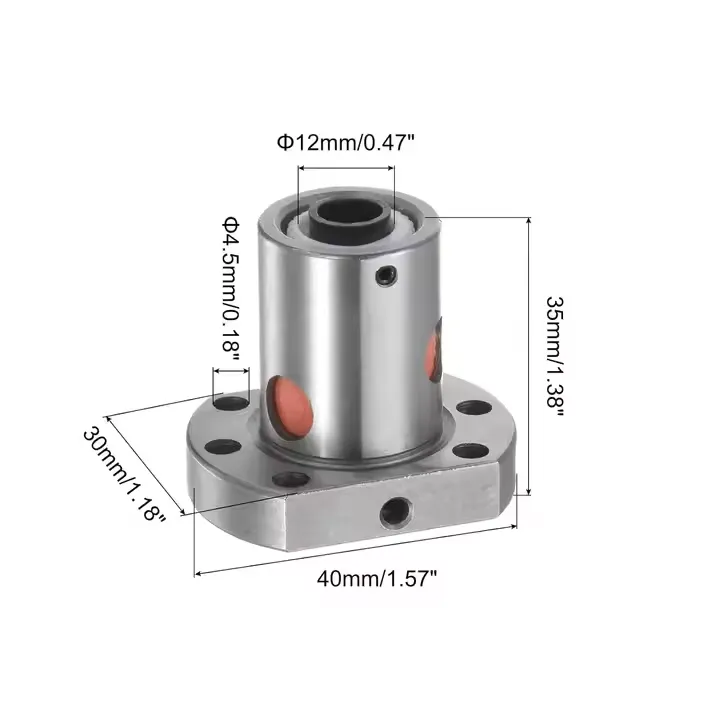

Diameter range: from 4mm to 100mm, customized according to customer requirements.

Lead (Pitch): Standard lead and special lead can be customized to meet the needs of different speeds and control accuracy.

Length: customized according to customer’s specific application scenarios, supporting long stroke design.

Precision grade: C5, C7, C10 and other precision grades can be selected to ensure that the transmission precision meets the industry standard or higher.

3. Product material

Screw material: High quality alloy steel, stainless steel or tungsten carbide coating is used to improve wear resistance, corrosion resistance and fatigue strength.

Nut material: Alloy steel, stainless steel and special alloy options are also available to ensure a perfect match with the screw and long-term stable operation.

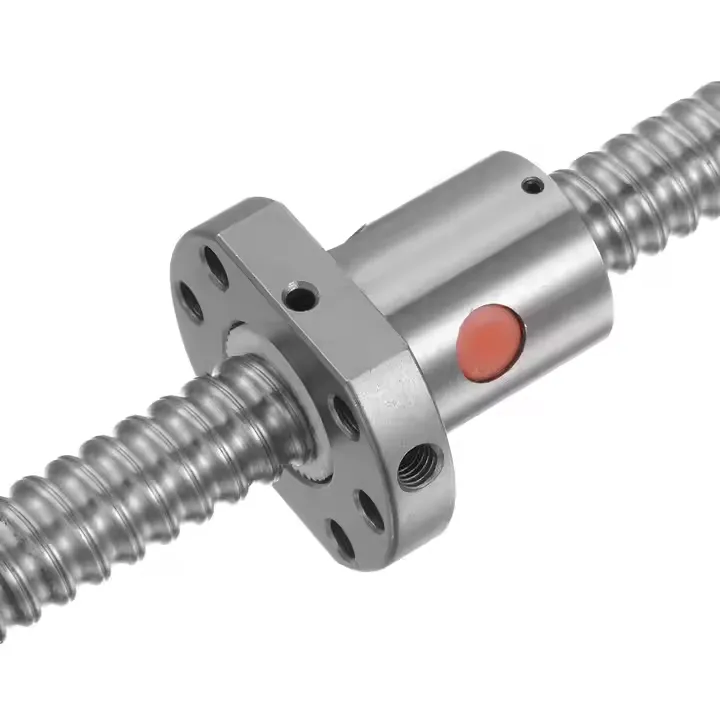

Ball material: High precision hard alloy steel balls are selected to ensure low friction, high efficiency and long life.

4. Product Craftsmanship

Precision machining: Advanced CNC lathe and grinder are used for precision machining to ensure the dimensional accuracy and surface finish of each part.

Heat treatment: After strict heat treatment process, the hardness and toughness of the material is enhanced to prolong the service life.

Assembling and testing: Each set of ball screw nut is strictly assembled and dynamically tested to ensure smooth transmission, low noise and no obvious wear.

5. Product use

Automation equipment: such as robot arms, automatic assembly lines, etc., to achieve precise positioning and high-speed movement.

CNC machine tools: Provide precise feed control to ensure machining accuracy and surface quality.

Precision Measuring Instruments: Used for fine-tuning devices to ensure accuracy and stability of measurement results.

Aerospace: for precise transmission in environments with high load and high reliability requirements.

6. Product customization

We offer a full range of customization services, including but not limited to:

Size customization: Precise design of screw diameter, lead and length according to your equipment size and installation space.

Load capacity customization: according to your application requirements, adjust the material and number of balls to meet different load requirements.

Precision customization: Provide different levels of precision customization according to industry standards or your special needs.

Special environmental adaptability customization: such as high temperature, low temperature, corrosive environment and other special applications, we can provide the corresponding material and coating treatment solutions.

Frequently Asked Questions

Q1: How to determine the required specification of Ball Screw Nuts?

A: Please provide your application scenario, load requirements, accuracy needs and installation space, etc. Our professional team will recommend the most suitable specifications for you.

Q2: What is the lead time for customized products?

A: Delivery time usually depends on the degree of customization and production arrangement, and is usually completed within 2-4 weeks after order confirmation. Please contact our customer service for specific lead time.

Q3: How do you guarantee the quality of customized products?

A: We have a perfect quality management system, from raw material purchasing to finished product testing, every process is under strict quality control. All products are provided with warranty service.

Q4: How to solve the problem if I encountered during the use?

A: Our customer service team is online 24 hours a day to answer your questions at any time. For technical problems, we will provide detailed technical support and solutions.

Choose our customized ball screw nut to give your equipment a more accurate and efficient drive system. Contact us today to start your customized journey!