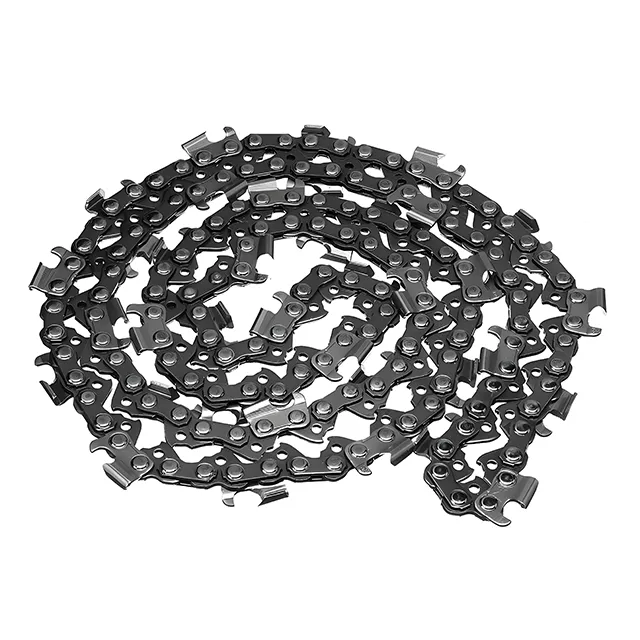

Custom Aerospace High Performance Light Alloy/Aluminum/Stainless Steel Saw Chain CNC Parts

Place of Origin:Fujian, China

Type:Broaching, DRILLING, Etching / Chemical Machining, Laser Machining, Milling, Other Machining Services, Rapid Prototyping, Turning, Wire EDM

Micro Machining or Not:Micro Machining

Model Number:CMP-66

Brand Name:JSD

Product name:coustom chain saw parts

Service:Customized OEM

Material:Stainless Steel

Process:Cnc Machining+deburrs

Application:Industrial Equipment

Surface treatment:Plating

Keyword:CNC Macining Parts

Equipment:CNC Machining Centres

Name:Customized Machined CNC Machining

Item:CNC Precision Machining Part

Description

Product Overview

Our custom aerospace high performance light alloy / aluminum / stainless steel saw chain CNC parts are designed to meet the demanding performance standards of the aerospace industry. The use of advanced CNC machining processes ensures that each part is of high precision, quality and reliability, and is an indispensable and critical component in aerospace equipment.

Material Advantages

1. Light alloy: High-quality light alloy materials are selected, featuring low density and high strength, which can effectively reduce the overall structural weight while maintaining excellent mechanical properties, helping to improve the fuel efficiency and flight performance of aerospace vehicles and reduce operating costs.

2. Aluminum: Pure aluminum and aluminum alloy materials have good electrical conductivity, thermal conductivity and corrosion resistance, easy to process and form, to meet the requirements of complex parts design, and to further optimize the weight distribution under the premise of ensuring structural strength.

3. Stainless steel: Stainless steel materials have excellent corrosion resistance, can resist the aerospace environment of a variety of chemical erosion, to ensure that the parts in the long-term use of the stability and reliability of the process, especially suitable for withstanding high stress and harsh environmental conditions of the components.

CNC machining process highlights

1. High-precision machining: With advanced CNC machining equipment and precise programming technology, we are able to realize high-precision control of part dimensions with extremely small tolerance range, ensuring perfect coordination with other aerospace components and improving the assembly precision and performance stability of the whole system.

2. Complex shape machining capability: With the flexibility and precision of CNC machining, we can manufacture saw chain parts of various complex shapes to meet the aerospace industry’s demand for unique structures and functions, providing strong support for innovative design.

3. Surface quality optimization: through the fine machining process and surface treatment technology, the surface finish of the parts is high, which reduces friction resistance and wear, improves the service life and working efficiency of the parts, and also helps to improve the overall performance of aerospace vehicles.

Performance Characteristics

1. HIGH RELIABILITY: In the aerospace field, reliability is crucial. Our saw chain CNC parts undergo rigorous quality testing and performance verification to ensure stable and reliable operation even under extreme conditions, providing a solid guarantee for the successful completion of aerospace missions.

2. High strength and durability: Whether it is vibration and shock in high-speed flight, or in the complex and changeable atmospheric environment, these parts have excellent strength and durability, and can withstand prolonged high-intensity use, reducing maintenance frequency and replacement costs.

3. Optimized dynamic performance: After careful design and precise processing, the dynamic performance of saw chain parts is optimized, which can maintain smoothness in high-speed operation, reduce noise and vibration, and improve the comfort and safety of aerospace equipment.

Customized services

We understand that each aerospace project has its own unique needs, so we offer a full range of customized services. From the design of parts, selection of materials to the determination of processing technology, we can be customized according to the specific requirements of customers, to ensure that the final product fully meets the specific needs and technical specifications of the project, to provide customers with the best quality and most suitable solutions.

Quality Assurance

We have a strict quality management system, from the procurement of raw materials to production and processing of each link are strictly quality control and testing. Using advanced testing equipment and technical means, we conduct comprehensive testing on the dimensional accuracy, surface quality and material properties of the parts to ensure that every saw chain CNC part that leaves the factory meets or exceeds the standard requirements of the aerospace industry, providing customers with assured and reliable products.

Choosing XIAMEN GOLDCATTLE’s customized aerospace high-performance light alloy / aluminum / stainless steel saw chain CNC parts is choosing superior quality, advanced technology and reliable performance to help your aerospace project achieve complete success.