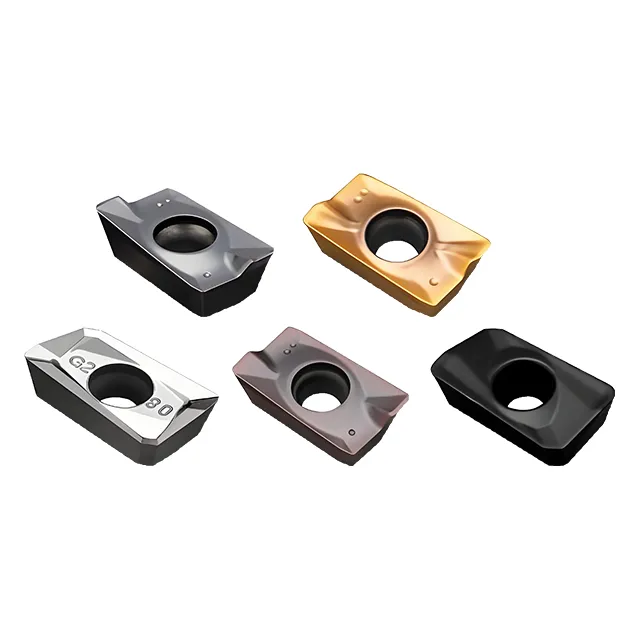

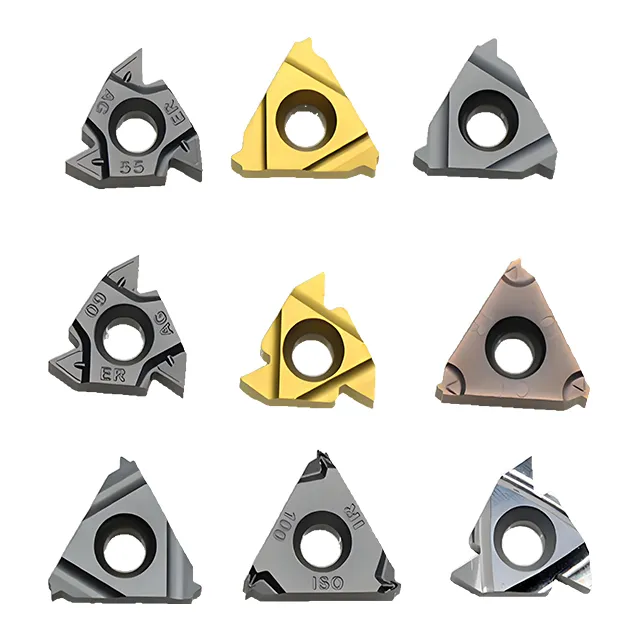

Custom mold processing high precision tungsten steel threaded inserts CNC machining parts

Place of Origin:Fujian, China

Type:Broaching, DRILLING, Etching / Chemical Machining, Laser Machining, Milling, Other Machining Services, Rapid Prototyping, Turning, Wire EDM

Micro Machining or Not:Micro Machining

Model Number:CMP-68

Brand Name:JSD

Product name:Custom threaded inserts part

Service:Customized OEM

Material:Stainless Steel

Process:Cnc Machining+deburrs

Application:Industrial Equipment

Surface treatment:Plating

Keyword:CNC Macining Parts

Equipment:CNC Machining Centres

Name:Customized Machined CNC Machining

Item:CNC Precision Machining Part

Description

Product Description

Our custom mold processing high precision tungsten steel threaded insert CNC machining parts are high quality key components specially created for the mold manufacturing industry. With its excellent material properties, precision machining process and highly customized service, it can meet the strict requirements of various complex molds for high precision, high strength and wear resistance, effectively improve the performance and service life of molds, and provide reliable solutions for mold processing enterprises.

Material Advantage

Adopting tungsten steel as raw material, tungsten steel has extremely high hardness and wear resistance, which can maintain excellent shape precision and surface quality and reduce wear and deformation during frequent opening and closing operations of the mold and friction with processed materials, thus significantly extending the maintenance cycle and overall service life of the mold. Its high-strength characteristics enable it to withstand greater injection pressure, stamping pressure and other stresses generated during the work of the mold, to ensure that in the harsh working conditions are still stable and reliable, not easy to damage. At the same time, tungsten steel also has good thermal stability, in the high temperature environment is not easy to soften and deformation, to ensure that the mold in the process of high temperature processing of dimensional accuracy and performance stability, for high-precision mold processing provides a solid foundation.

CNC machining precision

With the help of advanced CNC machining technology, we are able to realize ultra-high precision machining of threaded inserts. From the pitch of the thread, the angle of the tooth type to the external dimensions of the insert, hole diameter and other key parameters, can be accurately controlled within a very small tolerance range. For example, the machining accuracy of the threads can reach ±0.005mm, which makes the inserts and other parts of the mold fit more closely and accurately, effectively preventing the leakage of plastic or metal melts in the mold cavities, and improving the sealing of the molds and the quality of the molded products. Precision CNC machining also ensures the surface finish of the inserts, reduces the coefficient of friction, further improves the mold release performance and overall efficiency, reduces surface strains and imperfections, and improves the appearance and dimensional accuracy of the product.

Customized Services

We understand that different molds have different design and functional requirements, so we offer a full range of customized services. Customers can communicate with our professional technical team according to the specific requirements of their own molds, such as specific thread specifications, insert shapes, dimensional accuracy, surface treatment and so on. Based on the detailed drawings or technical parameters provided by the customer, we will use advanced CAD/CAM technology to carry out personalized design and programming to ensure that each threaded insert can be accurately adapted to the customer’s mold to meet its unique process requirements. Whether it is used in injection molds, die-casting molds or stamping molds and other different types of molds, we can customize the most suitable threaded insert solutions for customers, to help customers create high-performance, high-quality mold products.

Quality Assurance

We have established a strict quality control system during the whole production process. From the procurement inspection of raw materials, to the monitoring of each process during CNC machining, to the final inspection of finished products, we strictly follow international standards and industry norms. We use high-precision inspection equipment, such as CMMs and thread gauges, to conduct comprehensive and detailed inspections of the dimensional accuracy, shape and positional tolerances, thread parameters, and surface quality of threaded inserts to ensure that every product that leaves the factory meets or exceeds the customer’s expected quality standards. At the same time, we also provide perfect after-sales service, for customers in the use of any problem encountered in the process, can respond in a timely manner and provide effective solutions, so that customers have no worries, feel free to choose our products.

Choosing XIAMEN GOLDCATTLE’s custom mold machining high precision tungsten steel threaded insert CNC machined parts is choosing professional, precise, durable and customized mold parts solutions, injecting strong competitiveness into your mold manufacturing business, and jointly promoting the development and progress of the mold industry.