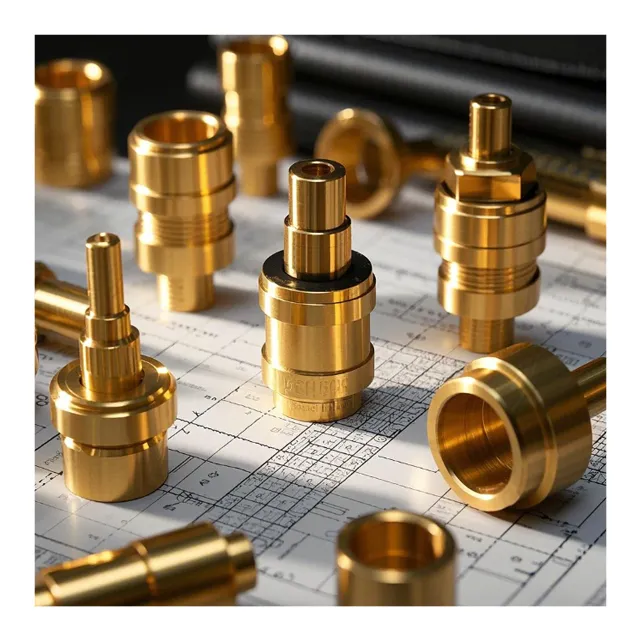

Professional CNC Brass Parts Customization Service | Precision Machining & Non – standard Parts Production

Materials

Common materials: H59, H62, H65 brass, etc.; red copper, bronze, and alloy brass (containing lead/tin/nickel) are also available for selection. Performance advantages: corrosion resistance, high electrical/thermal conductivity, and easy to machine by cutting.

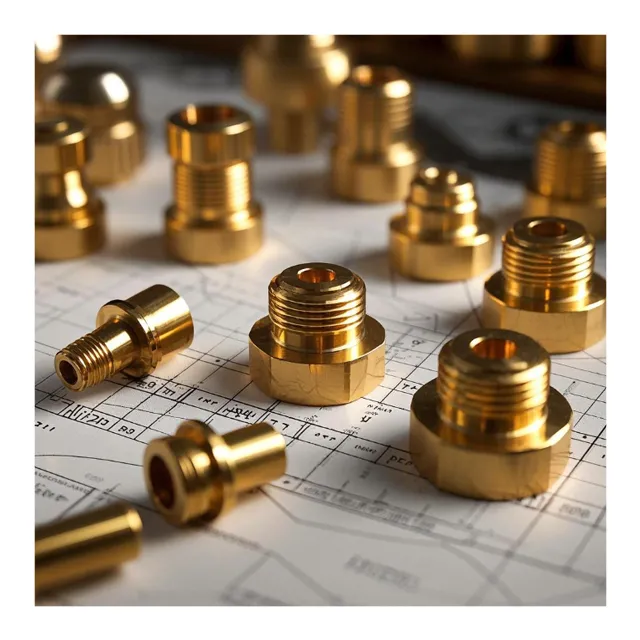

Machining Accuracy

Conventional tolerance: ±0.01mm; high precision can reach ±0.005mm (requiring special process support). Surface roughness: Ra0.6 (finish machining), Ra1.6 (rough machining).

Dimensional Capabilities

The maximum machining diameter is ≤200mm, and the length is ≤500mm (turned parts); four – axis/five – axis machining for complex structures is supported.

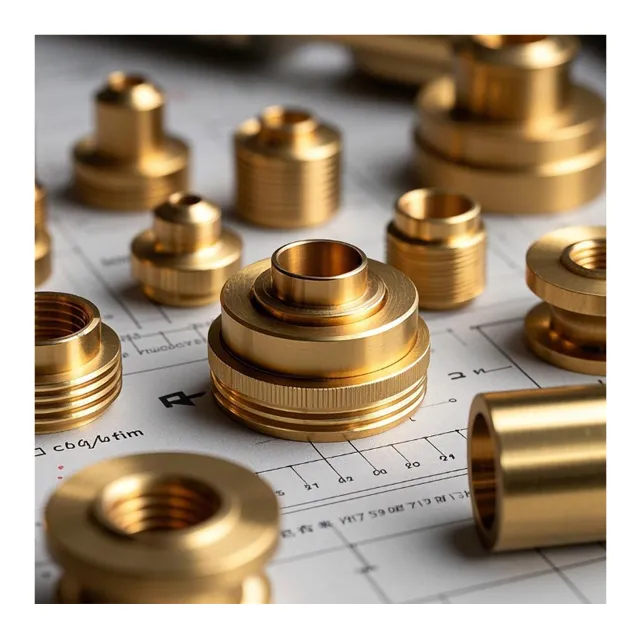

Surface Treatment

Conventional processes: polishing, sandblasting, anodizing (multiple colors available). Special processes: nickel/chrome electroplating, electroless plating, complying with RoHS environmental protection standards.