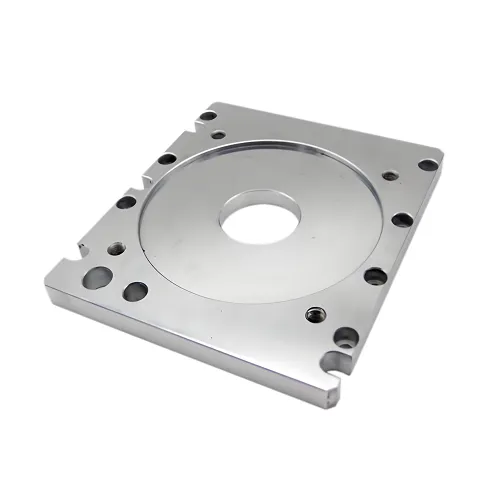

Customized CNC machining parts for new energy equipment

Place of Origin : XiaMen, China

Brand Name : JSD

Model Number : CNC-12

Type : Broaching, DRILLING, Etching / Chemical Machining, Laser Machining, Milling, Other Machining Services, Rapid Prototyping, Turning, Wire EDM

Micro Machining or Not : Micro Machining

Material : aluminum

Service : Customized OEM

Finish : Oxidation Etc

Size : Technical Drawing

Tolerance : +/-0.05mm

Process : Cnc Machining+deburrs

OEM/ODM : OEM ODM CNC Milling Turning Machining Service

Drawing Format : 2D/(PDF/CAD)3D(IGES/STEP)

Quality control : 100% Inspection Berore Shipment

Materials Avaliable : Stainless steel/Aluminum/Brass

Description

【Product Overview】

When faced with complex design challenges, our custom CNC stainless steel parts offer a precise and reliable solution. Utilizing advanced CNC machining technology, our team of professionals is able to transform your complex designs into highly accurate and consistent stainless steel parts.

【Product Features】

1. Customized services: fully customized CNC machining services based on your drawings and specifications.

2. Complex Design Capability: Specialized in dealing with complex geometries and precise tolerance requirements, ensuring that every detail is perfectly rendered.

3. High-quality materials: Using high-quality stainless steel to ensure the corrosion resistance and mechanical strength of the parts.

4. Precision machining: Utilizing the latest CNC equipment to achieve high precision and repeatable machining results.

5. Wide range of applications: suitable for aerospace, medical devices, automation equipment and many other industries.

【Customization Process】

1. Demand communication: Communicate with customers in detail to clarify design requirements and production standards.

2. Design Review: A team of professional engineers reviews the design drawings to ensure machinability and cost-effectiveness.

3. Sample production: rapid sampling to verify the accuracy and feasibility of the design.

4. Mass Production: After sample confirmation, enter mass production stage.

5. Quality Inspection: Strict quality control process to ensure each part meets the standard.

6. Delivery and after-sales service: deliver products on time and provide perfect after-sales service.

Why choose us?

● Professional technology: We have many years of CNC machining experience and a team of professional technicians who are able to cope with all kinds of complex design challenges.

● Quality Assurance: We adhere to a strict quality management system to ensure the quality and performance of each part.

● Rapid Response: Our rapid response capability is able to meet the demand for urgent orders and just-in-time deliveries.

● Cost-effective: By optimizing the design and production process, we provide cost-effective custom solutions.

Conclusion: Choose our customized CNC stainless steel parts to bring your complex designs to life. We are committed to meeting your every need with the highest quality service, precision craftsmanship and reliability.