Precision size custom plastic injection molded parts

Place of Origin : XiaMen, China

Brand Name : JSD

Model Number : PP-05

Product Name : Injection Molding Parts

Material : PP/PC/PS/PE

Service : Molding / Mass Production

Surface Finish : As per customer’s requirement

Size : Customized

Application : Wide range, according to customer’s requirement

QC : 100% quality control

Certification : ISO9001

Customization : OEM

Tolerance : +/-0.005

Description

Professional Injection Molding Services: Creating Your Custom Plastic Part Manufacturing Solution

In a competitive market environment, accurate plastic part manufacturing is the key to product success. We provide professional injection molding services, focusing on customized high-quality, high-precision plastic parts to meet the needs of individualized, high-performance components in a variety of industries.

【Core Advantages】

1. Advanced technology and equipment: We use industry-leading injection molding technology, equipped with high-precision injection molding machines and automated production lines to ensure that each batch of parts meets the highest standards.

2. Customized design: Our design team has rich experience in providing customized solutions throughout the whole process, from conceptual design to final product, according to customers’ specific requirements.

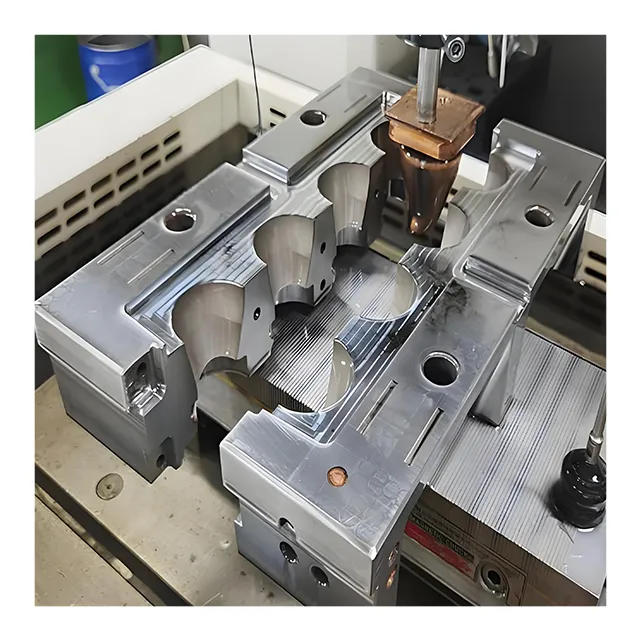

3. Precision Mold Manufacturing: With a professional mold design and manufacturing team, we are able to respond quickly to market changes and provide customers with high-precision, long-life injection molds.

4. Strict quality control: We implement ISO quality management system and strictly control raw materials, production process and finished product testing to ensure stable and reliable product quality.

5. One-stop service: From raw material procurement, mold development, injection molding production to post-processing, packaging and transportation, we provide one-stop service, so that our customers can save their efforts.

【Application Fields】

Our customized plastic parts are widely used in many industries such as automotive, medical, electronics, home appliances, toys and so on. Whether it is complex internal structural parts or exquisite decorative parts in appearance, we can create satisfactory products for our customers with professional technology and rigorous attitude.

【Manufacturing process】

1. Demand analysis: In-depth communication with customers to clarify product demand and specifications.

2. Design and development: product design and mold design according to the demand, to ensure the rationality and feasibility of the design.

3. Mold Manufacturing: Adopt high-precision CNC processing and heat treatment technology to manufacture injection molds that meet the requirements.

4. Injection molding production: Under strict control of process parameters, carry out injection molding production to ensure stable product quality.

5. Post-processing and testing: Post-processing such as deburring, grinding and assembly of finished products, and strict quality testing to ensure that the products meet customer requirements.

【Customer Service】

We know that customer satisfaction is the cornerstone of enterprise development. Therefore, we always put customer needs in the first place and provide a full range of customer service. Whether it is pre-sales consultation, technical support, or after-sales service, we will be dedicated to provide customers with the best service experience.

Choosing our professional injection molding service is choosing a reliable partner. Let us work together to create a better future!