Custom Matte Color 50ML-500ML PET Plastic Medicine Spray Paint Bottle

Place of Origin : Fujian, China

Brand Name : JSD

Model Number : IMP-52

Plastic Modling Type : Injection

Product name : Custom Matte Color 50ML-500ML PET Plastic Medicine Spray Paint Bottle

Material : ABS/PA66/PP/PC/PMMA/PSU/PCTG/TPE/TPU/PBT

Color : Custom Color

Size : Customer Size

Shape : Customized Shapes

Logo : Customer Logo

Drawing Format : 2D/(PDF/CAD)3D(IGES/STEP)

Service : Customized OEM

Certification : ISO9001

MOQ : 1 Piece

Description

I. Product Overview

Customized plastic medical spray paint bottles are packaging containers specifically designed for the medical industry, used for storing and dispensing various types of medical spray paint products. We offer comprehensive customization services to meet the specific needs of different customers.

II. Product Features and Advantages

High-Quality Plastic Materials

Select high-quality plastics that meet medical-grade standards, such as polyethylene (PE), polypropylene (PP), etc., to ensure compatibility and safety with medical spray paint.

The materials have good chemical stability and can effectively prevent reactions with the components of the spray paint to ensure the quality of the medicine.

Precise Spray System

Equipped with a carefully designed spray head that can achieve a uniform and fine spray effect, ensuring the accurate distribution of the spray paint each time it is used.

The design of the spray head can be adjusted according to customer requirements to meet different spray patterns and dosage needs.

Strict Sealing

Adopt advanced sealing technology to ensure that the medical spray paint inside the bottle does not leak during storage and transportation, maintaining the stability and effectiveness of the product.

Customized Design

Shape and size: The shape and size of the bottle body can be customized according to customer needs to adapt to different packaging specifications and usage scenarios.

Color and marking: Offer a variety of color options and can conduct personalized marking printing according to the customer’s brand image and regulatory requirements.

Bottle cap and spray head styles: Provide multiple types of bottle caps and spray heads, such as rotary caps, press caps, child-resistant caps, etc., to meet different usage needs and safety requirements.

Exquisite Production Process

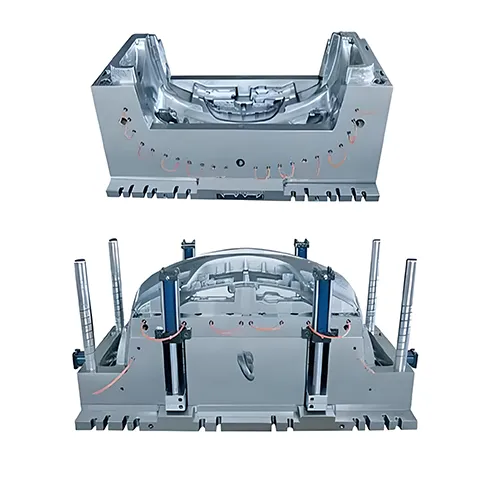

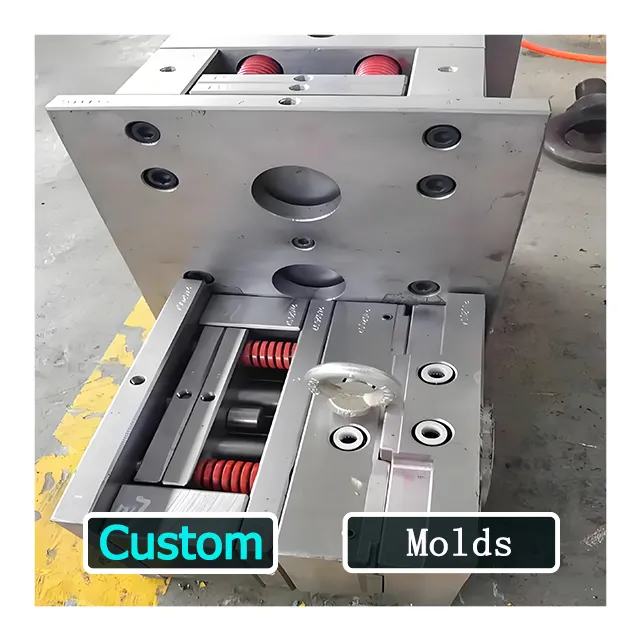

Use advanced injection molding processes to ensure the accuracy and consistency of the bottle body, with a smooth and flawless surface.

A strict quality control process runs through the entire production process to ensure that each spray paint bottle meets high-quality standards.

Compliance with Regulatory Requirements

The design and production of the product strictly follow the relevant regulations and standards of the medical industry to ensure the safety and compliance of the packaging.

III. Customization Service Process

Demand Communication

Have detailed communication with customers to understand their requirements for the function, appearance, capacity, usage scenarios, etc. of the spray paint bottles.

Solution Design

Based on customer requirements, the professional design team provides the initial design solution, including the bottle structure, spray head design, color and marking layout, etc.

Sample Production

Produce samples for customers to conduct actual tests and evaluations, and optimize and adjust the design based on customer feedback.

Batch Production

After determining the final design solution, conduct large-scale batch production to ensure the timely delivery of high-quality products.

Quality Inspection

During the production process, conduct strict quality inspections at each stage, including raw material inspection, semi-finished product inspection, and finished product inspection.

Packaging and Delivery

Conduct safe packaging of the finished products, select the appropriate transportation method to ensure the products are delivered to customers on time and in good condition.

IV. Quality Control and Inspection

Raw Material Inspection

Conduct strict incoming inspection on plastic raw materials, testing their physical properties, chemical properties, and hygiene indicators to ensure they meet medical-grade standards.

Production Process Monitoring

Monitor the process parameters in real-time during the injection molding process, such as temperature, pressure, time, etc., to ensure the consistency and stability of the products.

Finished Product Inspection

Conduct comprehensive performance inspections on the finished spray paint bottles, including sealing tests, spray effect tests, capacity tests, appearance inspections, etc.

Microbial Detection (If Required)

For some special medical spray paint products, conduct microbial limit tests to ensure the products are not contaminated.

V. Application Fields

Customized plastic medical spray paint bottles are widely used in the following medical fields:

Dermatology drugs: Such as external spray preparations for treating skin diseases.

Wound care: Spray products used for wound disinfection and hemostasis.

Oral care: Such as spray medicines for oral anti-inflammation and pain relief.

VI. Customer Support and After-Sales Service

Provide professional technical consultation to help customers select the most suitable spray paint bottle design and materials.

Respond promptly to customers’ questions and feedback and solve the problems encountered by customers during use.

Provide quick solutions to product quality problems, including return and replacement services and replenishment services.

We are committed to providing customers with high-quality and reliable customized plastic medical spray paint bottle product services to meet the strict packaging requirements of the medical industry and the evolving market demands.