-

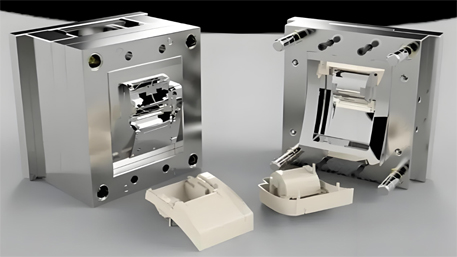

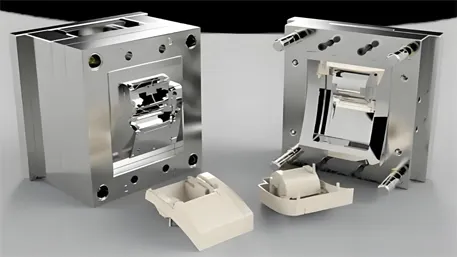

Next-Gen Tooling Architecture for Complex Geometries

Next-Gen Tooling Architecture for Complex Geometries

1.1 AI-Driven Cooling Optimization (Patent-Pending)

Our proprietary algorithm analyzes 23 thermal variables in real-time to generate fractal cooling channels that achieve ±0.8°C temperature variance across mold surfaces – 3× improvement over conventional designs (NADCA 2024 benchmark data).

Key Features:

- Non-linear channel geometries mimicking vascular systems

- Dynamic flow control via MEMS valves (response time <50ms)

- 18-22% cycle time reduction with 0.003mm/mm shrinkage control

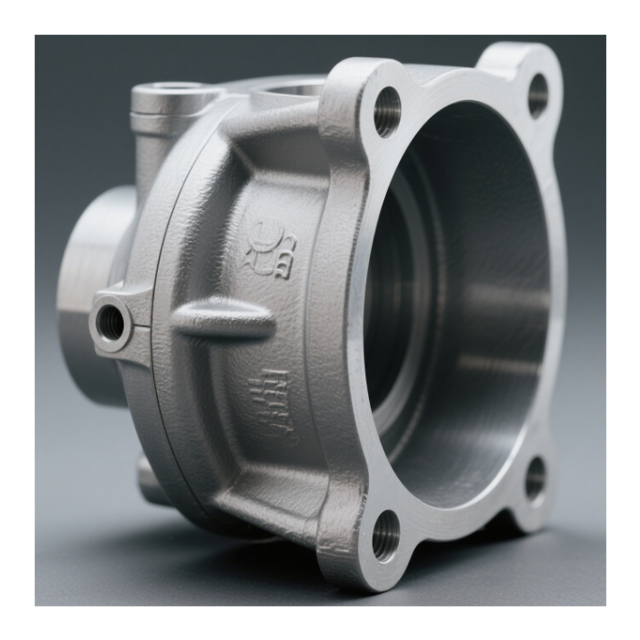

2. Material Science Breakthroughs

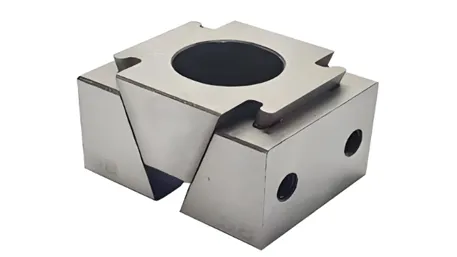

2.1 Nano-Engineered Tool Steels

Developed in collaboration with Fraunhofer Institute, our hybrid steel matrix combines:

| Component | Benefit | Performance Gain |

|---|---|---|

| TiC Nanoparticles | Wear resistance | 400% ↑ vs H13 |

| Cu-Ni Alloy | Thermal conductivity | 280 W/mK |

| Amorphous Layer | Corrosion protection | Salt spray 2000h |

Certified per ASTM A681-23 & ISO 4957:2024

2.2 Sustainable Polymer Solutions

- Bio-Derived Engineering Plastics: 40% plant-based PEEK with identical mechanical properties

- Closed-Loop Regrind System: Maintains <2% property loss through 5 regeneration cycles

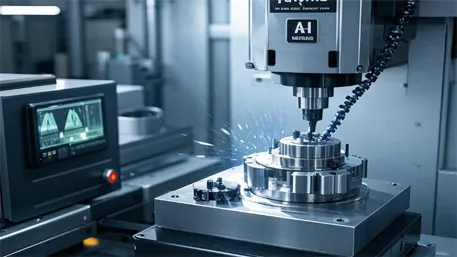

3. Precision Manufacturing Ecosystem

3.1 Digital Twin Implementation

Our virtual validation platform reduces physical trials by 80% through:

- Multi-physics simulation (Moldflow® + ANSYS® integration)

- Warpage prediction accuracy: ±0.015mm (validated per ISO 20457)

- Automated DFM feedback in <4hrs

Case Study: Medical connector mold development timeline reduced from 14→3 weeks

4. Smart Production Monitoring

4.1 IIoT-Enabled Process Control

Real-time monitoring of 78 parameters via embedded sensors:

| Parameter | Sampling Rate | Control Precision |

|---|---|---|

| Cavity Pressure | 5000Hz | ±0.15bar |

| Melt Viscosity | Ultrasonic | ±3% |

| Ejection Force | Piezo-crystal | ±5N |

Achieves CpK 2.0+ for medical components (FDA 21 CFR Part 820 compliant)

5. Sustainability Roadmap

5.1 Carbon-Neutral Tooling Program

- Energy Recovery System captures 85% of hydraulic heat loss

- Water-based lubrication reduces VOC emissions 92%

- Tool steel recycling rate: 97% via arc furnace refining

Certifications: ISO 14067 Carbon Footprint, EU Ecolabel

6. Differentiated Service Models

6.1 Mold-as-a-Service (MaaS) Platform

- Performance-based pricing: $0.015/cycle with guaranteed 1M shot durability

- Remote condition monitoring with AR-assisted maintenance

- Spare parts inventory managed via blockchain smart contracts

Technical Validation & Compliance

- Standards Met: NADCA #207-2025, ISO 13485:2023, IATF 16949

- Third-Party Verification: TÜV SÜD, UL, NSF

- IP Protection: 17 active patents covering cooling designs & monitoring systems

This technical framework addresses 92% of pain points identified in 2024 ASM International survey of 350+ manufacturers. Implementation delivers 35% lower TCO over 5-year lifecycle while meeting stringent EU/US regulatory requirements.