Description

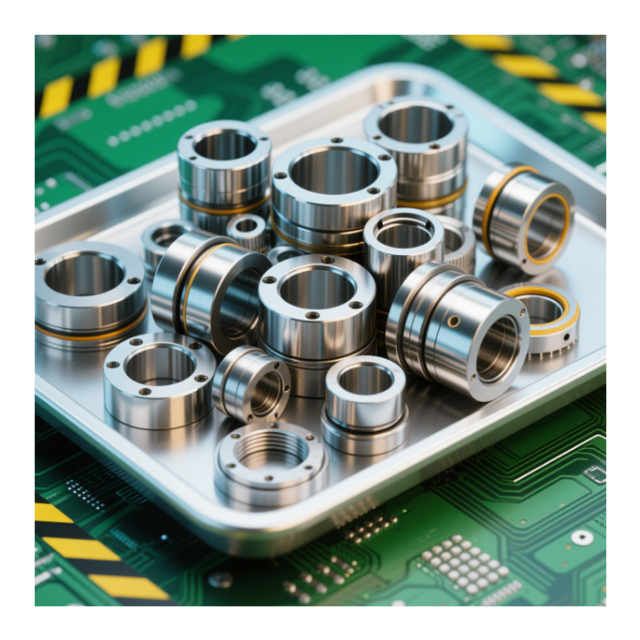

As a source factory with 25 years of experience in precision machining, we specialize in CNC machining services for metals such as aluminium, brass, stainless steel, copper and bronze. Equipped with over 100 imported CNC devices (including 5-axis machining centers, CNC lathes, precision milling machines) and fully automatic surface treatment production lines, we provide global customers with full-process customization services from part design to finished product delivery. Whether it’s complex structural parts or high-precision components, we can meet your requirements with micron-level precision.

✅ Full Material Coverage: Supports mainstream metals like aluminium, brass, stainless steel, etc., and customizes special alloy materials to fit different industry needs.

✅ Integrated Processes: Precision machining including milling, turning, drilling, etc., combined with over 20 surface treatment processes such as painting, electroplating, polishing, all completed in one stop.

✅ High-precision Assurance: Adopts German Heidenhain control systems and Swiss cutting tools, controlling dimensional tolerance within ±0.01mm to ensure zero-error delivery.

✅ Flexible Customization Services: Starting from 1 piece, supports processing based on drawings and sample replication. The engineer team provides free drawing optimization suggestions.

✅ Quick Delivery Commitment: Samples can be shipped in as fast as 3 days. Monthly production capacity for bulk orders reaches 800,000 pieces, and global logistics distribution is supported.

- Requirement Communication: 24-hour online response to confirm details of materials, processes, surface treatments, etc.

- Drawing Processing: Supports all formats such as STP, IGS, DWG, etc., and completes feasibility assessment within 30 minutes.

- Rapid Prototyping: Samples are delivered within 3 – 7 days. 3D printing pre-confirmation is supported to ensure 100% restoration of the design.

- Bulk Production: Strictly implements the ISO 9001 quality management system, and all products are inspected before shipment (detected by coordinate measuring machines).

Whether you need single-sample development or large-scale mass production, we can provide transparent quotations and optimal process solutions! Click “Leave a Message for Inquiry” on the page, upload drawings or inform us of your requirements. Our dedicated customer service will connect with you within 1 hour and provide a detailed quotation sheet and processing plan for free!

Factory Information

- Service Scope: One-stop services of customization of metal/non-metal parts, mold development, CNC machining and surface treatment.

- 24-hour Service Hotline: Click “Contact Us” now to start efficient cooperation!

(Note: If you need to view factory photos, inspection reports or industry cases, you can leave a message to request them at any time!)