In daily automotive use, door hinges act as the “joint components” connecting the vehicle body and doors, with their precision directly impacting door sealing, switching smoothness, and service life. Traditional standardized hinges often suffer from issues like rattling, play, or excessive wear under complex conditions, while customized CNC machined door hinges achieve a quality leap from “functional” to “excellent” through data-driven precision manufacturing. This article analyzes how to create “zero-defect” door hinge solutions from the dimensions of customization value, core processes, and quality control.

1. Why Standard Hinges Fail to Meet High-End Demands

Q: What’s the Essential Difference Between Custom and Ordinary Hinges?

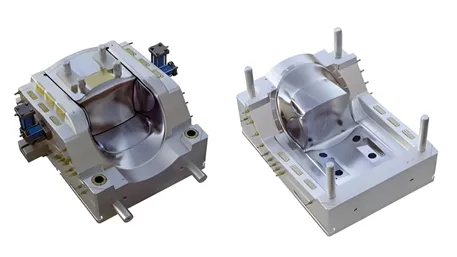

Standard hinges are mostly produced by die-casting or general CNC machining, with limitations in tolerance control (±0.1mm level), material matching (e.g., common carbon steel), and surface treatment (simple galvanizing). In contrast, custom hinges focus on “precise connection”:

- Deep Deep Operating Condition Adaptation: Tailored to vehicle type (SUV/sedan/new energy), door weight (30-50kg), and hinge arm thickness (3-5mm), pin shaft diameter (8-12mm) is customized. For example, electric door hinges require reinforced wear-resistant coatings (hardness ≥HV500) to handle high-frequency switching (over 50 times daily).

- Data-Driven Design: CAE simulation of load distribution during door opening/closing (max opening angle 120°, load 200N·m) precisely calculates hinge hole position tolerances (coaxiality ≤0.02mm), preventing door sagging caused by excessive clearance (sag >1mm affects sealing).

Case Evidence: A luxury car brand achieved a 70% reduction in door rattle complaints and extended service life from 5 to 8 years with custom hinges, verifying customization’s direct impact on reliability.

2. How Core Processes Achieve Millimeter-Level Precision Breakthroughs

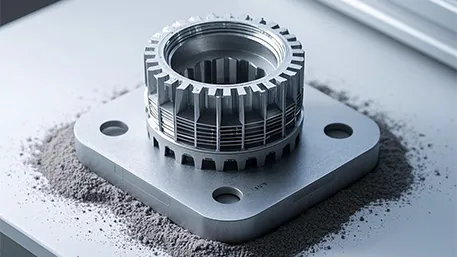

1. Turn-Mill Composite Machining: Multi-Feature One-Pass Machining

Complex structures of door hinges (curved arms, stepped shaft holes, mounting bosses) require turn-mill composite centers for high-precision machining:

- 5-Axis RTCP Function: Adjusting tool angle via B-axis rotation (±30°) maintains uniform cutting force when machining hinge arm surfaces, controlling surface roughness below Ra1.6μm—30% higher precision than 3-axis machining.

- Full-Process Integrated Machining: A zero-point positioning system (repeatability ≤0.005mm) completes turning (pin shaft outer diameter), milling (mounting surface), and drilling (bolt holes) in one setup, reducing cumulative errors from multi-machine transfer by 80% (e.g., hole spacing tolerance risks).

2. End-to-End CNC Machining Data Closed-Loop

Every stage from blank to finished product is precisely controlled by data:

- Programming Phase: UG/CAM software generates tool paths while simulating stress concentration areas (e.g., bending points) on hinge arms, optimizing fillet radii (R5-R8mm) to avoid post-machining stress cracking.

- Machining Execution: Real-time collection of 20+ parameters (spindle torque ≤15N·m for stainless steel, feed rate 2000mm/min for aluminum) triggers automatic speed reduction when vibration amplitude >0.03mm, increasing tool life by 40%.

- Inspection Phase: CMM (Coordinate Measuring Machine) scans hinge hole spacing (tolerance ±0.015mm) and pin shaft straightness (≤0.01mm/m), uploading data to the MES system for traceable machining records.

3. Quality Control: Full-Chain Rigorous Verification from Material to Finished Product

1. Multi-Dimensional Performance Inspection System

- Material-Level Strict Screening:

-

- Aluminum Hinges: Spectral analysis of Si/Mg content (6061-T6: Si≤0.4%, Mg≤1.5%), hardness testing (HB90-110) ensures fatigue resistance.

-

- Stainless Steel Hinges: Magnetic particle inspection for surface cracks, intergranular corrosion testing (GB/T 4334) verifies high-temperature acid/alkali resistance.

- Finished Product Functional Testing:

-

- Opening/Closing Force Test: Special equipment simulates 100,000 cycles (speed 0.5m/s), controlling force fluctuation within ±5N for consistent feel.

-

- Salt Spray Test: 1000-hour neutral salt spray (NSS) with no corrosion (galvanized layer ≥8μm), meeting coastal area requirements.

2. Intelligent Defect Prevention Technology

- First-Article Five-Inspections System: Programmers, operators, quality inspectors, process engineers, and quality managers jointly verify 15 key dimensions (hinge hole spacing ±0.01mm, pin shaft diameter ±0.005mm), intercepting batch deviations at the source.

- AI Visual Full Inspection: Linear array cameras complete surface scanning in 0.3 seconds, identifying scratches/deformations >0.05mm depth with a miss rate <0.005%—meeting OEM zero-defect acceptance standards.

4. How Small-Batch Customization Balances Efficiency and Precision

Q: Does Custom Production Mean Long Lead Times?

Three process innovations shorten customization cycles by 40% and boost efficiency by 50%:

- Modular Process Library: Feature modules for hinge arms, pin shafts, and bushings reuse 70% of processing parameters for similar parts, cutting programming time from 8 to 3 hours.

- Automated Flexible Production: Truss robots with quick-change fixtures (model switching <3 minutes) enable mixed production of multi-variety small batches (100-500 pieces), increasing equipment utilization to >85%.

- Tool Life Prediction: IoT sensors monitor coating tool wear in real time (e.g., 150 pieces per edge for stainless steel), automatically triggering tool change alerts to avoid dimensional fluctuations from excessive wear.

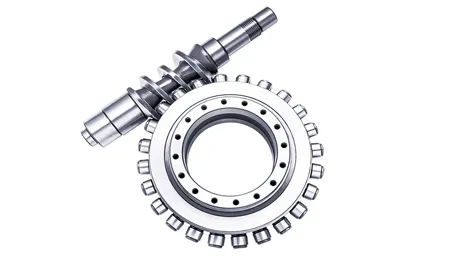

5. Core Considerations for Choosing Custom Hinges

- Data Traceability: Qualified suppliers should provide complete documents including CAE simulation reports, CNC machining parameters, and full-dimension inspection reports to ensure quantifiable performance verification.

- Technical Composite Capability: Required capabilities include turn-mill composite machining (supporting RTCP function), precision grinding (pin shaft outer diameter accuracy IT5 level), and surface treatment (Dacromet/electrophoretic coating) to meet different vehicle needs.

- Response Speed & Adaptability: Sample delivery within ≤20 days after drawing confirmation supports OEM synchronous development; lightweight design capabilities for new energy vehicles (aluminum hinges reduce weight by 40% compared to steel).

Conclusion

The value of custom CNC machined door hinges lies in defining “connection precision” with data and ensuring “switching quality” with processes. As consumers demand higher NVH performance (noise, vibration, harshness) and new structures like electric doors and opposing doors become popular, customized solutions with “data-driven design + precision manufacturing processes” are becoming essential for automakers to create high-end driving experiences. From durability upgrades in traditional ICE vehicles to intelligent innovations in new energy cars, custom hinges will support “10,000-level reliability” with “millimeter-level precision,” making every door opening/closing a silent testimony to quality.

(Contact us now to get your exclusive door hinge customization solution and free process diagnosis)