In the fuel supply system of automotive engines, fuel injectors serve as core components for achieving “precise fuel injection,” with their precision directly influencing air-fuel ratio control, fuel efficiency, and emission performance. Traditional standardized injectors often suffer from poor atomization, leakage, or excessive wear under complex conditions, while customized CNC machined fuel injectors achieve a technological leap from “fuel spraying” to “intelligent control” through data-driven precision manufacturing. This article dissects how to create “micron-level precision” injector solutions from the dimensions of customization value, core processes, and quality control.

1. Why Standard Fuel Injectors Struggle to Meet China 6/New Energy Requirements

Q: What Are the Core Advantages of Custom Fuel Injectors?

Standard injectors, mostly produced via generic machining, have three critical limitations:

- Inadequate Orifice Precision: Traditional drilling tolerances (±0.005mm) fail to meet the strict requirements of China 6 engines for nozzle diameters (0.1-0.3mm), which ideally require tolerances of ±0.001mm.

- Crude Flow Channel Design: Lack of flow channel optimization for engine conditions (e.g., direct injection pressure of 20-35MPa) results in fuel atomization particle sizes >80μm (ideal ≤50μm).

- Suboptimal Material Matching: Ordinary stainless steel nozzles lack corrosion resistance, leading to orifice blockages in ethanol gasoline environments (flow deviation >5% after 1 year of use).

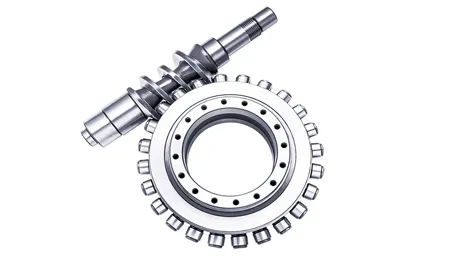

In contrast, custom injectors focus on “precision injection”:

- Deep 工况适配 (Deep Operating Condition Adaptation): Tailored to engine type (gasoline/diesel/hybrid), the number of injection holes (4-12) and cone angles (60°-90°) are customized. For example, hybrid-specific injectors are reinforced for high-pressure pulse resistance (withstanding 500Hz high-frequency opening/closing).

- Data-Driven Design: CFD fluid simulation optimizes hole arrangement (hole spacing tolerance ±0.002mm), and engine combustion models (e.g., maximum cylinder pressure 25MPa) calculate needle valve clearance (controlled at 0.001-0.003mm), ensuring spray cone angle deviation <1°.

2. How Core Processes Achieve Micron-Level Precision Breakthroughs

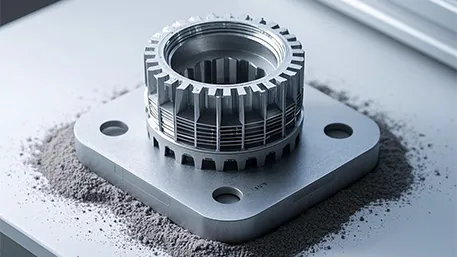

1. Ultra-Precision Microhole Machining: Pushing Diameter Limits

Machining tiny holes (φ0.1-0.5mm) in fuel injectors integrates three core technologies:

- High-Speed Spindle Machining: Using 20,000-40,000rpm high-frequency electric spindles with diamond-coated micro drills achieves hole diameter tolerance ±0.001mm and surface roughness Ra≤0.2μm.

- Stepwise Machining Strategy: Follows a three-step process (“drilling→reaming→honing”), leaving 0.005mm margin at each step. Reaming uses pulse feeding (0.002mm/rev) to avoid tool deflection in microhole machining (deflection >0.002mm triggers scrap).

- Thermostatic Machining Environment: Maintains workshop temperature at 20±0.5℃ with air-float vibration-isolated machines, eliminating thermal deformation effects (temperature change of 1℃ causes hole diameter change of ~0.0005mm).

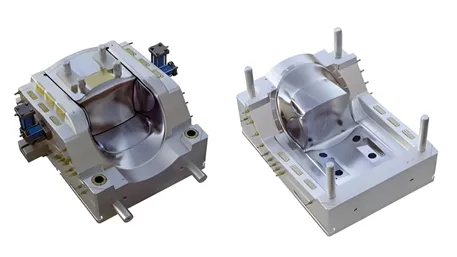

2. Turn-Mill Composite + 5-Axis Machining: Complex Structures in One Setup

Special-shaped surfaces of injector bodies (e.g., flow channels, sealing cones) require high-end CNC machines:

- 5-Axis Interpolation: Tilting via A-axis (±15°) machines sealing cones (taper tolerance ±0.001°), keeping the tool perpendicular to the cone normal. Combined with laser tool setting (accuracy ±0.0005mm), it achieves sealing surface roughness Ra≤0.1μm.

- Full-Process Integrated Machining: A zero-point positioning system (repeatability ≤0.001mm) completes body turning (outer diameter accuracy IT5), milling (mounting surface flatness 0.002mm), and microhole machining in one setup, avoiding coaxiality errors >0.01mm common in traditional multi-step processes.

3. End-to-End CNC Machining Data Closed-Loop

- Programming Phase: UG/CAM software generates tool paths while simulating injector hole flow characteristics (rated flow deviation ≤±1%), optimizing hole mouth rounding (R0.05-0.1mm) to reduce fuel flow resistance.

- Machining Execution: Real-time collection of 30+ parameters (spindle vibration threshold 0.02mm, cutting force limit 80N for stainless steel) triggers automatic shutdown for anomalies, boosting microhole machining yield from 70% to 98%.

- Inspection Phase: CMM scans hole positional tolerance (±0.003mm), and a flow test bench (accuracy ±0.5%) verifies spray uniformity, with data uploaded to MES for traceable digital records.

3. Quality Control: Full-Chain Rigorous Verification from Material to Finished Product

1. Multi-Dimensional Performance Inspection System

- Material-Level Strict Screening:

-

- Body Material: Spectral analysis of high-strength stainless steel (e.g., 17-4PH, 15-17% Cr), grain size inspection (≥Grade 8) ensures corrosion resistance; ceramic nozzles undergo fracture toughness testing (KIC≥45MPa・m½).

- Finished Product Functional Testing:

-

- Seal Test: Holds 20MPa pressure for 30 seconds with leakage <0.1ml/min (common injectors often leak >0.5ml/min).

-

- Flow Consistency Test: At 80℃ fuel temperature, flow deviation between holes ≤±1.5% ensures uniform cylinder combustion.

-

- Fatigue Life Test: Simulates 1 million opening/closing cycles (300Hz frequency), with needle valve wear <0.0005mm to prevent injection volume drift from wear.

2. Intelligent Defect Prevention Technology

- First-Article Seven-Inspections System: Programmers, operators, quality inspectors, process engineers, equipment technicians, metrologists, and quality managers jointly verify 20 key dimensions (hole diameter ±0.001mm, needle valve clearance ±0.0005mm), intercepting micron-level deviations.

- AI Visual Full Inspection: Nanometer-precision linear cameras complete hole scanning in 0.5 seconds, identifying burrs >0.002mm height or material defects with a miss rate <0.001%, meeting strict China 6 emission consistency requirements.

4. How Small-Batch Customization Balances Precision and Efficiency

Q: Does Micron-Level Precision Mean Low Efficiency?

Three process innovations boost efficiency by 60% and reduce costs by 30%:

- Parametric Programming Templates: 10+ process templates for hole machining and sealing surface milling reuse 90% of parameters for similar parts, cutting programming time from 12 to 2 hours.

- Automated Inspection Integration: Robots automatically load/unload into CMM and flow test benches, reducing single-piece inspection time from 10 to 2 minutes for seamless “machining-inspection” integration.

- Precision Tool Life Management: A life database for micro drills (e.g., 50 pieces/edge) and IoT sensor wear monitoring (via cutting force fluctuation) ensure tool change accuracy error <0.0003mm.

5. Core Considerations for Choosing Custom Fuel Injectors

- Data Transparency: Suppliers should provide CFD flow analysis reports, CNC machining parameter logs, and full-dimension inspection reports (including 3D hole coordinates) for traceable injection performance.

- Technical Composite Capability: Required capabilities include ultra-precision microhole machining (≤φ0.1mm), high-temperature/high-pressure testing (35MPa+), and surface coating (e.g., PVD diamond-like coatings) to handle diverse fuels (gasoline/diesel/hydrogen).

- Response Speed & Adaptability: Sample delivery within ≤25 days supports OEM engine synchronous development; new energy-specific design capabilities (e.g., electric injector solenoid hole accuracy IT4 level).

Conclusion

The value of custom CNC machined automotive fuel injectors lies in defining “micron-level injection precision” with data and achieving “1-million-cycle reliable control” with processes. Against the backdrop of stricter global emissions standards and accelerating new energy vehicle adoption, customized solutions with “data-driven design + ultra-precision manufacturing” are becoming key for automakers to break through engine thermal efficiency bottlenecks and reduce emissions. From China 6 upgrades in traditional ICE vehicles to electrified system innovations in new energy cars, custom injectors will drive “engine-level transformation” with “nanometer-level precision,” making every drop of fuel a cornerstone of efficient and clean power.

(Contact us today for your exclusive injector customization solution and free flow characteristic analysis)