Description

25-Year Precision Machining Expert · Custom CNC Milling & Turning for Metal Parts — Micron-Level Accuracy, 1 Piece MOQ

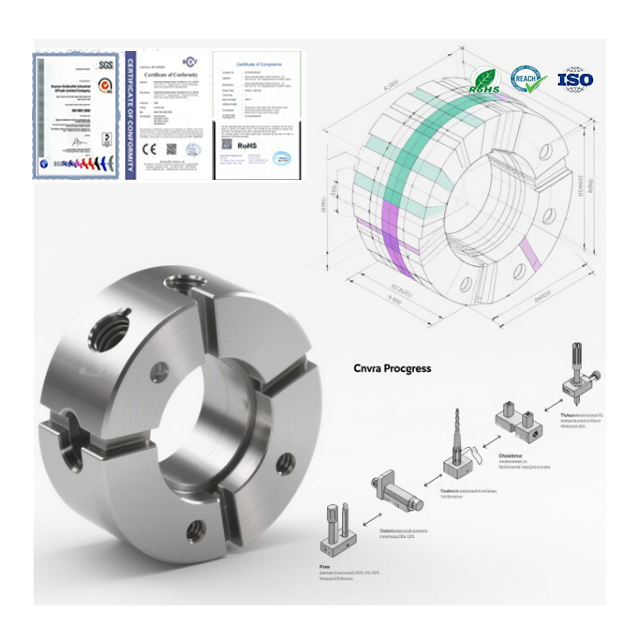

As a source factory with 25 years of expertise in precision machining, we specialize in custom processing of metal parts (aluminum, copper, bronze, brass, etc.) using 5-axis CNC machining centers and high-precision CNC lathes. Equipped with fully automated inspection equipment, we deliver ±0.005mm tolerance and Ra 0.8μm surface roughness for complex curved structures and high-precision shaft components across industries.

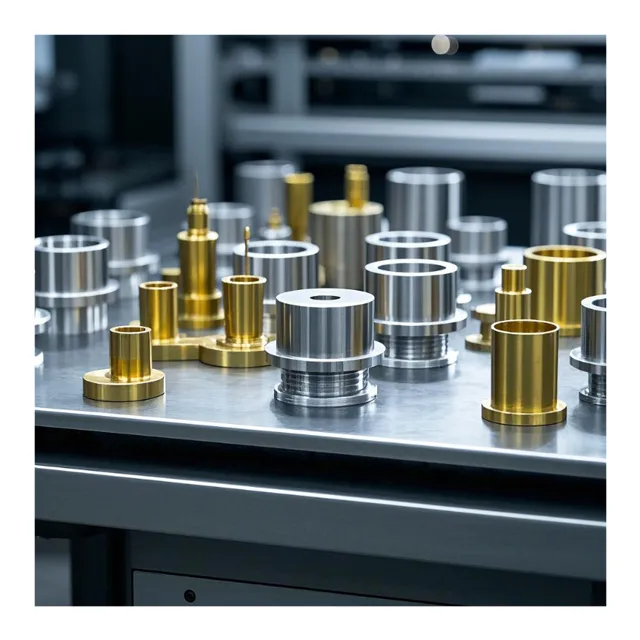

✅ Material Flexibility: Support mainstream metals like aluminum (6061/7075), brass (H62/H65), and bronze (tin bronze/aluminum bronze). Custom special alloys with free material selection consultation.

✅ Comprehensive Processes: 20+ processes including CNC milling, turning, wire EDM, and precision drilling. 5-axis machining for complex surfaces, enabling one-stop multi-process completion.

✅ Surface Treatment Options: 10+ finishes (anodizing for wear resistance, electroplating for aesthetics) to meet corrosion resistance, conductivity, and decorative requirements.

✅ Flexible Ordering: 1-piece MOQ (no minimum limit), drawing-based processing (STP/IGS/DWG supported), sample replication, and free drawing optimization by our engineering team.

✅ Quality Assurance: ISO 9001-certified factory with 100% full inspection (CMM measuring, roughness testing) to ensure zero-defect products.

🔧 State-of-the-Art Equipment: Imported German DMG and Japanese Mazak CNC machines improve complex part machining efficiency by 60%.

💡 Technical Expertise: 15-member senior engineering team provides process optimization and cost control solutions, reducing development costs by 30%.

🌍 Global Service: FOB Ningbo port, supported by DHL/UPS/sea freight with 100% on-time delivery. Serving 500+ enterprises in Europe, America, and Southeast Asia.

- Submit Requirements: Click “Leave a Message” to upload part drawings (STP/IGS/DWG, etc.) or describe material/size specifications.

- Solution Confirmation: Engineers complete feasibility assessment within 2 hours, with detailed quotes and process consultations provided 1-on-1.

- Rapid Production: Samples shipped within 7 days, bulk orders delivered within 20 days (expedited orders available for as fast as 3 days).

Whether for single-sample prototyping or mass production, click “Leave a Message” to enjoy:

- Free Process Evaluation: Professional team optimizes machining plans to save time and costs.

- Transparent Pricing: $0.8–$15 per piece (specification-dependent), no hidden fees.

- Dedicated Support: 1-on-1 project management with real-time production and quality report updates.