Description

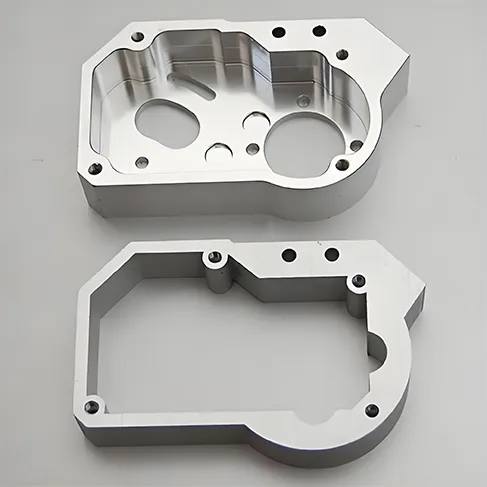

25-Year 5-Axis Precision Machining Expert · Metal Component Customization — Micron-Level Accuracy, Full-Industry Solutions

As a leading Chinese source factory for 5-axis CNC machining, we leverage German DMG MORI 5-axis machining centers and Japanese FANUC high-precision CNC lathes to deliver high-precision custom machining services for metals including stainless steel, brass, aluminum, and titanium alloy. From complex aerospace structural parts to medical precision components, we meet the extreme accuracy requirements of high-end manufacturing with ±0.005mm tolerance and aerospace-grade surface treatments.

✅ Material Flexibility:

- Stainless Steel (304/316L corrosion-resistant)

- Aluminum Alloy (6061-T6 high-strength/7075 aerospace-grade)

- Brass/Bronze (H65 free-cutting/tin bronze wear-resistant)

- Titanium Alloy (TA1 lightweight/GR5 high-strength)

Special alloy customization available with free material strength and machinability analysis

✅ Process Advantages:

- 5-Axis Machining: One-setup five-sided processing eliminates traditional tool change errors, improving complex surface machining efficiency by 80%.

- Turning-Milling Compound: Simultaneous turning and milling for high-precision forming of shaft/disc parts.

- Special Processing: Wire EDM (minimum hole diameter 0.1mm), deep hole drilling (length-diameter ratio 1:50), thread milling (accuracy grade 6H/6g).

- Surface Treatments: 20+ options including anodizing (hardness up to HV500+) and PVD coating (5x wear resistance improvement).

✅ Drawing Compatibility:

- Supports STEP/IGS/STL 3D models, DWG/DXF 2D drawings, and sample reverse scanning.

- Professional engineers review drawings within 2 hours and provide process optimization suggestions (cost reduction by up to 20%).

🔧 Advanced Equipment:

- German DMG CTX gamma 5-axis machine (positioning accuracy ±0.003mm, repeatability ±0.001mm).

- Japanese FANUC α-T21iB CNC lathe (spindle speed 8,000rpm, turning tolerance ±0.002mm).

- Hexagon CMM (inspection accuracy ±0.002mm, 100% full inspection for dimensional consistency).

💡 Technical Assurance:

- AS9100-certified factory adhering to PPAP and FMEA quality management systems.

- 15-member senior engineering team providing full-cycle technical support from design simulation (UG/CATIA) to mass production.

- Real-time processing monitoring (machine networking system) for remote progress and quality data access.

🌍 Global Service Network:

- Lead Times: Samples in as fast as 5 days (expedited channel), bulk orders with phased delivery options.

- Logistics: DHL/UPS 3-day global delivery, FOB Shanghai/Ningbo for sea freight, door-to-door customs clearance.

- Customer Cases: Serving Boeing, Medtronic, and other Fortune 500 companies, exporting to 30+ countries.

-

Submit Requirements:

- Click “Leave a Message” to upload drawings or sample photos.

- Specify materials, dimensions, surface treatments, and other key parameters.

(Free preliminary quotation and process plan)

-

Solution Confirmation:

- 1-on-1 consultation with engineers, including 3D machining simulation videos.

- Formal quotation and Gantt chart issued within 24 hours of confirmation.

-

Rapid Delivery:

- Sampling: 5–10 days (including prototyping and inspection).

- Mass production: 15–30 days (monthly capacity 500,000 pieces, small-batch trial production supported).

(Ultra-urgent orders negotiable for 72-hour express delivery)

📞 Exclusive Benefits:

- 50% discount on sample fees for new customers.

- Free full-dimension inspection reports for bulk orders (3 pieces included).

- Free mold storage for long-term cooperative customers.

Factory Information:

- Company Name: Jiangsu Jingmida Machinery Co., Ltd. (10-year Alibaba Gold Supplier)

- Service Hotline: +86-512-6688-XXXX

- Address: Precision Manufacturing Industrial Park, Suzhou Industrial Park, Jiangsu, China

(Note: For live machining site broadcasts, industry whitepapers, or inspection reports, feel free to request via message!)