1、Answer

There is no absolute superiority; it depends on requirements:

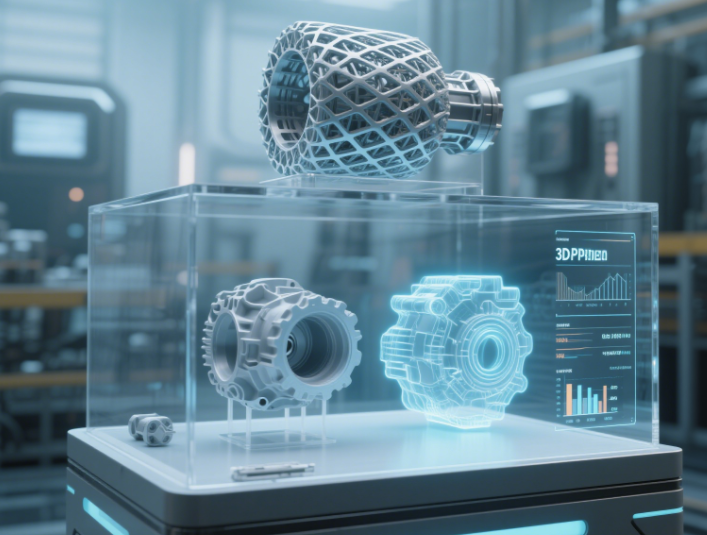

- 3D printing is better for: Low-volume production (<500 pieces), complex curved/hollow structures (e.g., aerospace engine blades), and customized personalization (e.g., medical prosthetics). It requires no molds and enables fast design iteration (new samples can be produced within 24 hours after design changes).

- Injection molding is better for: High-volume production (>10,000 pieces), regular geometric shapes (e.g., mineral water bottles), and low-cost needs (unit cost can be as low as $0.01 for injection molding vs. $1.50 for 3D printing). It suits standardized products.

2、Expansion

Core Dimension Comparison and Application Scenarios

| Comparison Dimension | 3D Printing (Additive Manufacturing) | Injection Molding (Subtractive/Molding) |

|---|---|---|

| Production Scale | Optimal for 1–1,000 pieces; batch costs increase exponentially (e.g., 1,000 pieces cost 3x more than 100 pieces) | Optimal for 10,000+ pieces; unit cost decreases with scale (100,000 pieces cost 1/3 of 10,000 pieces) |

| Design Freedom | Can print nested structures and internal channels (e.g., teapot-like hollow parts), supports topological optimization (reduces weight by 40% while maintaining strength) | Limited by molds; requires simplified structures (e.g., avoid deep undercuts, which would add 30% to mold costs via side core-pulling mechanisms) |

| Material Range | Covers plastics (PLA/ABS), metals (titanium/stainless steel), ceramics, and biological materials (e.g., degradable PLGA), but metal powders cost up to $500/kg | Mainly thermoplastics (e.g., PP/PE/PC) and some thermosets (e.g., epoxy resin); materials cost as low as $2/kg |

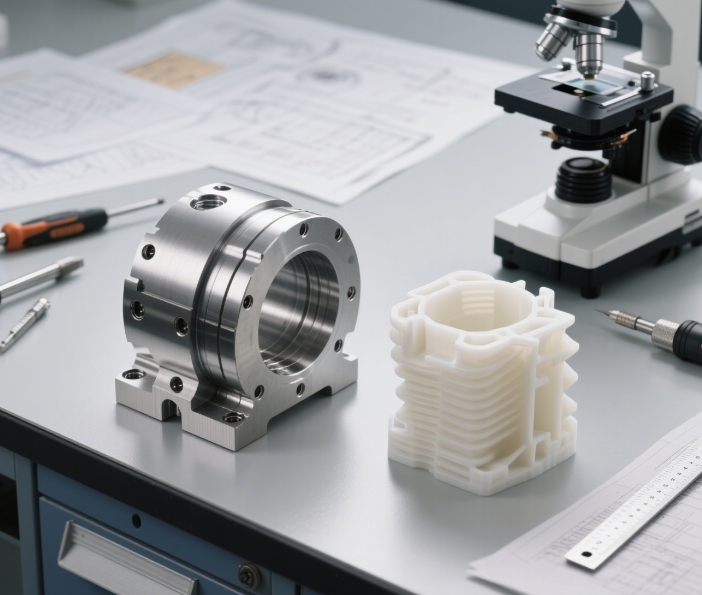

| Surface Precision & Strength | Metal parts achieve ±0.05mm accuracy and Ra1.6–6.3 surface roughness, with strength approaching 80% of forged parts | Achieves ±0.02mm accuracy and Ra0.8–3.2 surface roughness, with uniform structural strength suitable for cyclic loading (e.g., automotive gearboxes) |

| Typical Applications | Aerospace prototypes (e.g., rocket engine nozzles printed in 7 days), customized medical implants (e.g., patient-specific skull repair plates) | Daily products (e.g., 5 billion disposable cutlery produced annually), automotive components (e.g., 200,000 bumpers per mold annually) |

Complementarity and Technological Trends

- Prototype-Mass Production Link: 90% of injection-molded products are first validated via 3D printing (e.g., a smartphone manufacturer used SLS nylon to print 20 casing prototypes, optimizing design before tooling, saving $80,000 by reducing 5 trial runs).

- Rise of Hybrid Processes:

- Rapid Tooling: 3D-printed aluminum molds (5,000-cycle lifespan) cost 1/4 of steel molds, used for low-volume trial production (e.g., EV battery box samples).

- Multi-Material Printing: Machines like Stratasys J750 can print 7 materials simultaneously (soft/hard plastics + transparent parts), simulating injection molding’s two-color effects (e.g., one-click production of remote control casings with rubber buttons).

- Shifting Cost Thresholds: Traditional injection molding suits 10,000+ pieces, but as metal 3D printing speeds increase (e.g., Desktop Metal’s 1,000-pieces/hour capacity), its economic batch size is expanding from 100 to 1,000 pieces, potentially replacing some injection molding needs below 5,000 pieces in the future.

Conclusion: Choosing between 3D printing and injection molding boils down to balancing “design freedom/speed” vs. “scale efficiency/cost.” Just as the automotive industry uses 3D printing for engine manifolds (complex cooling structures) and injection molding for dashboards (high-volume low-cost), the two are not substitutes but complementary “addition-subtraction” tools in manufacturing.