1、Answer

The hardest materials for CNC machining are tungsten carbide (hardness up to 90 HRC), titanium alloys (e.g., Ti-6Al-4V with high toughness), and advanced ceramics (e.g., silicon carbide, hardness 2500 HV). They demand specialized tools (e.g., diamond/CBN cutters) and strict machining parameters due to extreme hardness, low thermal conductivity, or high chemical reactivity.

2、Expansion

Core Challenges and Material Characteristics

-

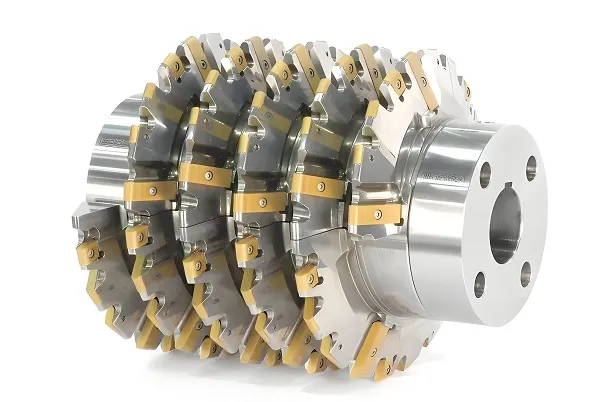

Tungsten Carbide (WC): The “Tool Steel Killer”

- Why It’s Difficult:

- Contains tungsten carbide particles bonded by cobalt (10–25%), hardness exceeds HRC 90 (3x harder than stainless steel), causing rapid tool wear (even carbide tools degrade after 30 minutes).

- Low thermal conductivity (10–40 W/m·K, 1/20th of aluminum), trapping 80% of cutting heat in tools, leading to thermal cracking.

- Machining Solutions:

- Must use polycrystalline diamond (PCD) or cubic boron nitride (CBN) tools (cost $500–$2,000 per insert), with cutting speeds ≤50 m/min (1/10th of steel).

- Requires precision grinders (e.g., CNC jig grinders) for final shaping, with coolant pressure ≥10 MPa to flush abrasive debris.

- Typical Applications:

- Industrial dies (e.g., wire drawing dies, lifespan 10x steel), aerospace turbine nozzles (heat resistance up to 1,400°C).

- Why It’s Difficult:

-

Titanium Alloys: The “Heat Trapper”

- Key Difficulties:

- High strength-to-weight ratio (e.g., Ti-6Al-4V tensile strength 900 MPa) combined with low thermal conductivity (6 W/m·K, 1/30th of aluminum), causing severe tool-chip adhesion at cutting edges (built-up edge).

- Chemical reactivity at high temperatures (≥600°C) forms hard titanium carbide on tool surfaces, accelerating wear.

- Machining Innovations:

- Use specialized coatings (e.g., AlCrN with oxidation resistance up to 1,100°C) on carbide tools, cutting speed limited to 30–60 m/min.

- Apply cryogenic cooling (liquid nitrogen at -196°C) to reduce tool temperature by 40%, extending tool life by 3x.

- Typical applications:

- Aircraft structural parts (e.g., Boeing 787 uses 15% titanium), medical implants (due to biocompatibility), but machining costs are 5–8x higher than aluminum.

- Key Difficulties:

-

Advanced Ceramics: The “Brittle Giant”

- Unique Challenges:

- Ultra-high hardness (e.g., zirconia: 1,200 HV; silicon nitride: 2,500 HV) but low fracture toughness (3–5 MPa·m¹/², 1/10th of steel), prone to micro-cracking during machining.

- Electrical insulation requires non-conductive tools (e.g., diamond grinding wheels), with material removal rates 100x lower than metal.

- Processing Methods:

- Primarily uses abrasive machining (grinding/polishing), with diamond wheel grit sizes as fine as 3 μm for surface finishes ≤Ra0.2μm.

- Hot isostatic pressing (HIP) may be needed post-machining to relieve internal stresses, adding 20–30% to production time.

- Typical applications:

- Semiconductor equipment components (e.g., silicon wafer carriers), automotive turbocharger bearings (wear resistance 10x steel), but scrap rates often exceed 25% due to brittleness.

- Unique Challenges:

Extreme Material Cases

- Diamond Composites: Polycrystalline diamond (PCD) compacts (hardness 7,000–8,000 HV) used in oil drill bits require laser machining or electron beam processing, as traditional CNC tools cannot cut them.

- Inconel 718 (Nickel-Based Superalloy): While not the hardest (HB 331), its high work-hardening rate (2x increase during cutting) and ability to retain 70% strength at 650°C make it extremely tool-destructive, requiring cobalt-based super-materials for cutting edges.

Conclusion: The “hardness” of CNC machining depends on a trilemma of hardness-toughness-thermal conductivity. Tungsten carbide is the “absolute hardness” benchmark, titanium alloys represent the “heat + adhesion” challenge, and ceramics embody the “brittleness + ultra-hardness” paradox. Machining these materials often requires hybrid processes (e.g., EDM + grinding) and specialized equipment, with costs 10–50x higher than conventional metals.