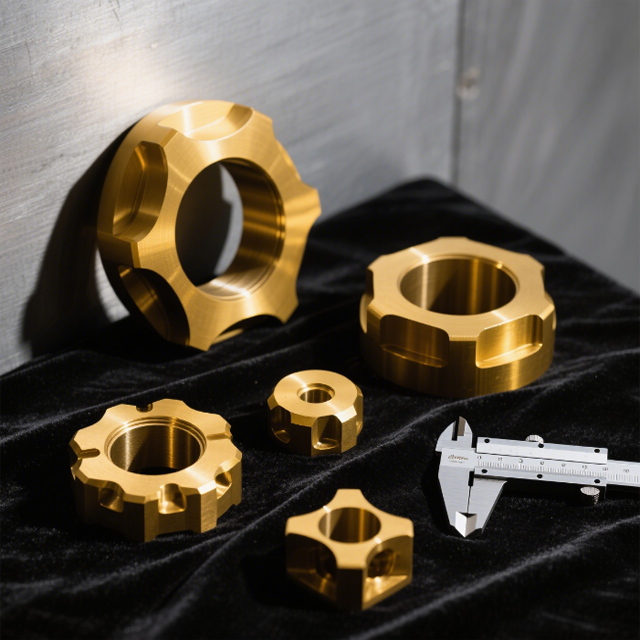

Custom Color Anodized CNC Metal Parts

| Category | Capabilities |

|---|---|

| Primary Materials | Aluminum 6061/7075 • Brass C360 • Copper |

| Anodizing Types | Type II (Standard) • Type III (Hardcoat) |

| Color Options | 200+ RAL/Pantone • Gradient Effects |

| Machining Tolerance | ±0.05mm (ISO 2768 Medium) |

| Maximum Part Size | 500×500×300mm |

| Surface Finishes | Bead Blasting • Brushed • Mirror Polish |

| Secondary Processing | Laser Engraving • EMI/RF Shielding |

| Certifications | ISO 9001 • RoHS • REACH |

| Production Lead Time | 15 Days (Standard) • 7 Days (Urgent) |

| MOQ | 1 Piece (Prototypes Welcome) |

Description

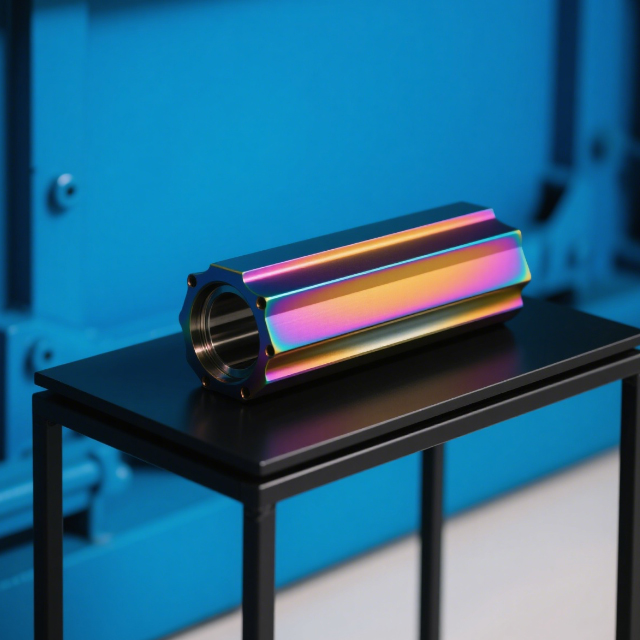

Revolutionize your product aesthetics with our precision CNC machining and advanced color anodizing services, specializing in vibrant, fade-resistant finishes for aluminum, brass, and copper components. Utilizing Swiss-made CNC centers and automated anodizing lines, we deliver visually striking parts with industrial-grade durability for consumer electronics, luxury goods, and architectural applications.

Advanced Anodizing Technology:

• Color Precision: Digital color-matching system achieves <0.5 ΔE value deviation from Pantone/RAL standards

• Sealing Process: Dual-sealed nano-pore structure withstands 500+ hours salt spray testing (ASTM B117)

• Special Effects: Two-tone gradients, conductive coatings (surface resistivity <100 mΩ), and UV-reactive finishes

Material-Specific Expertise:

-

Aluminum: Precision machining with stress-relieving protocols to prevent post-anodizing deformation

-

Brass/Copper: Custom electrolytic plating pretreatment for uniform oxide layer adhesion

-

Bimetallic Assemblies: Galvanic corrosion prevention through dielectric isolation techniques

Industry Applications:

✓ Consumer Electronics: Anodized iPad/MacBook chassis, wearables (Apple Watch bands)

✓ Automotive: Interior trim components with custom-branded textures

✓ Medical: Color-coded surgical instruments with antimicrobial coating options

✓ Industrial Design: Architectural hardware with weather-resistant coatings

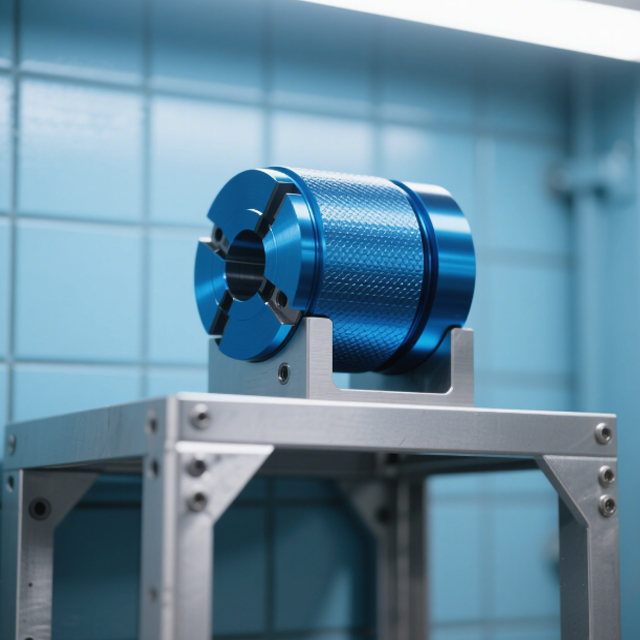

Integrated Manufacturing Process:

-

CNC Machining: 3/4/5-axis milling with custom fixtures for thin-walled components (0.3mm minimum)

-

Surface Prep: Automated ultrasonic cleaning and chemical etching

-

Anodizing: Temperature-controlled baths with titanium racking

-

Quality Control: Spectrophotometer verification and adhesion testing (ASTM D3359)

Technical Advantages:

• 100% color consistency across production batches

• Hardcoat anodizing up to 60μm thickness (MIL-A-8625 compliant)

• Conductive anodizing for EMI shielding (30-80 dB attenuation)

Value-Added Services:

-

Free DFM consultation to optimize designs for color transitions

-

Digital color mockups within 24 hours

-

Small-batch production with no tooling fees

Describe your part specifications and desired colors below – our finishing specialists will provide technical solutions within 1 business hours!