Answer

Sink mark is a common cosmetic defect in injection molding, manifested as sunken marks on the surface of plastic products, resembling dimples or grooves. After the plastic melt is injected into the mold cavity, during the cooling and solidification process, due to uneven cooling rates in different parts, in the thicker areas or near features such as ribs and bosses, the internal plastic shrinks more. However, the already solidified plastic on the surface cannot timely fill the space created by the shrinkage, and is thus pulled inwards, forming sink marks on the surface. It not only affects the aesthetic appearance of plastic products. In products with strict appearance requirements, such as electronic product casings and high – end daily necessities, sink marks are serious flaws. It may also affect the local dimensional accuracy of the product, having an adverse impact on assembly and related functions.

Extended Answer

In the field of plastic molding, sink marks are a problem that cannot be ignored, involving multiple technical aspects such as material properties, mold design, and injection molding processes. In – depth analysis of its formation mechanism, influencing factors, and countermeasures is of great significance for improving the quality of plastic products and reducing production costs.

Formation Mechanism of Sink Marks

Essentially, the generation of sink marks in plastics stems from the non – uniform shrinkage of plastics during the cooling and solidification process. When plastic materials are injection – molded, they are first heated to a molten state to have good fluidity and fill the mold cavity. After the melt fills the cavity, it enters the cooling stage. Since the temperature of the mold surface is relatively low, the surface layer of the plastic melt in contact with the mold rapidly cools and solidifies, forming a solid shell. The plastic inside the product, due to relatively slow heat dissipation, remains at a higher temperature and in a liquid or semi – liquid state. As the cooling continues, the internal plastic continues to shrink, but at this time, the solidified plastic on the surface restricts its shrinkage space. The stress generated by the internal shrinkage will pull the surface plastic. If the surface plastic cannot withstand this pulling force, it will sink inwards, thus forming sink marks.

Take a plastic product with a rib structure as an example. The wall thickness of the rib part is relatively thick, and its cooling rate is slower than that of the thin – walled part of the product. During the cooling process, the thin – walled part solidifies first, while the plastic inside the rib is still shrinking. When the stress generated by the shrinkage exceeds the bearing capacity of the surface plastic at the connection between the thin – wall and the rib, sink marks will appear on the surface of the connection.

Factors Affecting the Generation of Sink Marks

Plastic Material Properties: Different types of plastics have different shrinkage rates, which is a key internal factor affecting the generation of sink marks. Generally, crystalline plastics such as polyethylene (PE) and polypropylene (PP) have an obvious crystallization process during cooling, and the molecular chains are arranged more regularly and closely. Their shrinkage rates are relatively large, making them more prone to sink marks. In contrast, amorphous plastics such as polystyrene (PS) and polyvinyl chloride (PVC), with disordered molecular chain arrangements, have relatively small shrinkage rates, and the problem of sink marks is relatively less serious. In addition, even for the same type of plastic, the type and content of additives can also affect the shrinkage performance. For example, adding reinforcing materials such as glass fibers can improve the strength and rigidity of the plastic, but it will change the fluidity and shrinkage characteristics of the plastic, possibly leading to more serious sink mark problems.

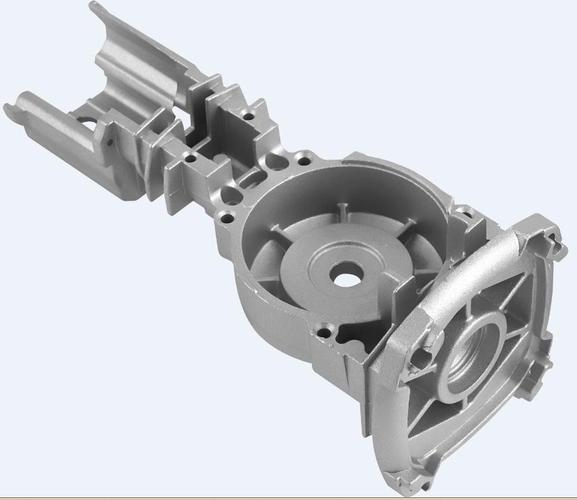

Plastic Product Design: The wall – thickness design of the product has a direct impact on the generation of sink marks. When the wall thickness of a plastic product is uneven, the thick – walled area cools slowly and shrinks more; the thin – walled area cools quickly and shrinks less. This shrinkage difference will cause internal stress concentration, thus forming sink marks at the sudden change of wall thickness or on the surface of the thick – walled area. For example, in the design of an electronic product casing, if the wall thickness of the posts used to fix the circuit board inside is too thick while the surrounding shell wall is thin, sink marks are very likely to appear at the roots of the posts. In addition, the design of structures such as ribs, bosses, and undercuts can also affect the situation of sink marks. Unreasonable rib layouts, overly high bosses, and complex undercut structures may all lead to an increase in local wall thickness or obstruction of plastic flow, thereby increasing the probability of sink mark generation.

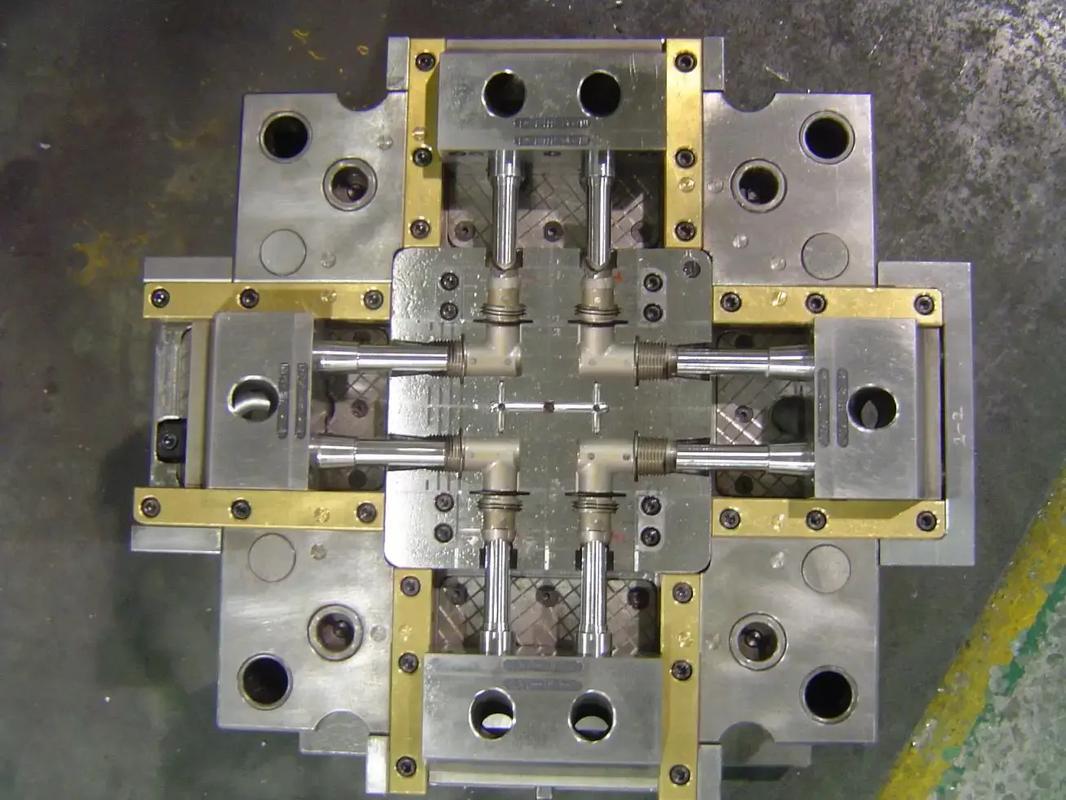

Injection Mold Structure: The design of the mold cooling system is an important external factor affecting sink marks. If the cooling water channels of the mold are distributed unreasonably, it will lead to uneven temperatures in different parts of the mold, causing inconsistent shrinkage of the plastic product during cooling. For example, if the cooling water channels are too far from the cavity surface or the cooling water flow rate is too slow, it will result in insufficient local cooling. The plastic product in this area has a long cooling time and large shrinkage, and is prone to sink marks. The position and size of the gate also have a significant impact on sink marks. If the gate is set in a thin – walled area, when the plastic melt flows towards the thick – walled area, it will have poor fluidity due to premature cooling and is difficult to fully fill the thick – walled area, resulting in shrinkage in the thick – walled area not being adequately compensated by plastic, thus generating sink marks. If the gate size is too small, it will increase the flow resistance of the plastic melt, resulting in a large pressure loss of the melt, which is also not conducive to material replenishment in the shrinking area, increasing the risk of sink marks.

Injection Molding Process Parameters: Process parameters during injection molding, such as injection pressure, packing pressure, packing time, melt temperature, mold temperature, and cooling time, will all affect the generation of sink marks. Insufficient injection pressure and packing pressure will cause the plastic melt to be unable to fully fill the mold cavity. Especially when the plastic product shrinks, there is not enough pressure to supplement the plastic to the shrinking area, resulting in sink marks. If the packing time is too short, stopping packing before the plastic product is completely cooled and solidified and the shrinkage is not completed, it cannot effectively compensate for the shrinkage, leading to the appearance of sink marks. If the melt temperature is too high, the shrinkage rate of the plastic will increase, and the cooling time of the plastic at high temperature is longer, making it more likely to have non – uniform shrinkage and increasing the possibility of sink marks. Both too high and too low mold temperatures are not conducive to the uniform cooling of plastic products. A too – high mold temperature will slow down the cooling rate of the plastic, resulting in a long and non – uniform shrinkage time; a too – low mold temperature will cause the plastic melt to cool rapidly, reducing its fluidity and possibly also triggering sink marks. Insufficient cooling time means that the plastic product is not fully cooled and solidified inside, and the shrinkage is incomplete, making it easy to have sink marks after demolding.

Detection and Prevention of Sink Marks

Detection Methods of Sink Marks: During the production of plastic products, it is crucial to detect sink marks in a timely and accurate manner. Visual inspection is the most commonly used method. By directly observing the surface of the plastic product, it is checked whether there are sunken marks to determine if there are sink marks. For some products with extremely high appearance requirements, it may be necessary to observe at a certain angle under specific lighting conditions to detect subtle sink marks. For some plastic products with complex internal structures or where sink marks are difficult to directly observe, non – destructive testing techniques can be used, such as X – ray inspection and ultrasonic inspection. X – ray inspection can penetrate the plastic product and analyze the density changes of the internal structure through imaging, thereby detecting internal defects caused by sink marks; ultrasonic inspection uses the propagation characteristics of ultrasonic waves in different media to detect whether there are abnormal reflection signals inside the plastic product to judge the situation of sink marks. In addition, the dimensional accuracy of plastic products can also be measured to indirectly determine whether there are sink marks. When sink marks cause local dimensional changes, key dimensions are measured by high – precision measuring instruments and compared with the designed dimensions. If the deviation exceeds the allowable range, there may be a sink mark problem.

Preventive Measures for Sink Marks: Prevention of sink marks should be considered from the product design stage. When designing plastic products, the wall thickness should be kept as uniform as possible to avoid sudden changes in wall thickness. For thick – walled areas that cannot be avoided, a gradual wall – thickness design can be adopted to make the wall – thickness transition smoother. Structures such as ribs and bosses should be designed reasonably, and the ratio of their wall thickness to the main wall thickness should be controlled. Generally, the wall thickness of ribs can be designed to be 50% – 60% of the main wall thickness. In terms of mold design, the cooling system design should be optimized to ensure a uniform distribution of cooling water channels, so that the temperature of each part of the mold is uniform. According to the shape and size of the plastic product, the diameter, quantity, and layout of the cooling water channels are reasonably selected to ensure the cooling effect. At the same time, the gate position and size should be set reasonably to ensure that the plastic melt flows evenly in the mold cavity. The gate should be preferably set in the thick – walled area to ensure that the thick – walled area can be fully filled. In terms of injection – molding process control, the process parameters should be optimized according to the plastic material properties and product requirements. Appropriately increase the injection pressure and packing pressure to ensure that the plastic melt can fully fill the cavity and provide sufficient filling pressure during shrinkage. Reasonably extend the packing time to allow the plastic product to complete shrinkage under sufficient packing. Control the melt temperature and mold temperature within an appropriate range to ensure the fluidity of the plastic melt and uniform cooling. In addition, the cooling time can be appropriately extended to ensure that the plastic product is fully cooled and solidified inside, reducing shrinkage deformation.

Solutions to Sink Marks

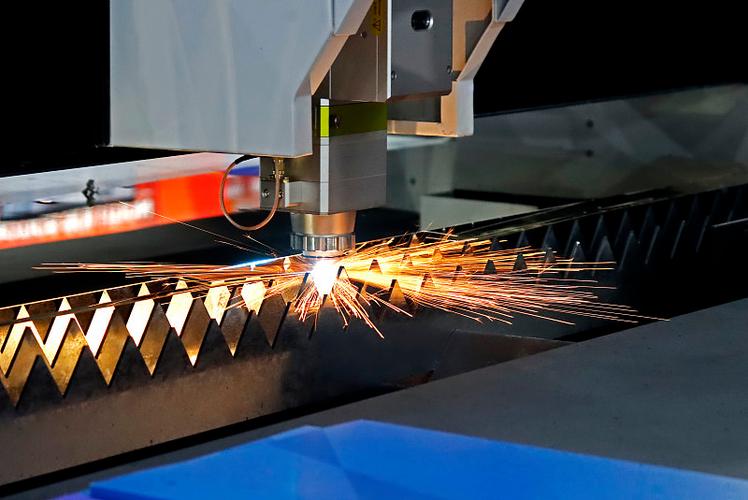

If sink marks have already appeared on plastic products, corresponding measures need to be taken to solve them. For sink marks caused by improper injection – molding process parameters, the process parameters can be adjusted to improve the situation. For example, appropriately increase the injection pressure and packing pressure, and extend the packing time to observe whether the sink marks improve. At the same time, the melt temperature and mold temperature can be adjusted, and the cooling time can be optimized. The best combination of process parameters can be found through multiple trial – moldings. If sink marks are caused by mold structure problems, the mold may need to be modified. For example, optimize the cooling water channels, increase the number of cooling water channels in areas with poor cooling effect or adjust their positions; optimize the gate, expand the gate size or change the gate position to improve the flow and filling of the plastic melt. For sink marks caused by unreasonable plastic product design, if the product allows design modification, the areas with uneven wall thickness can be optimized, and structures such as ribs and bosses can be adjusted. However, this often involves overall design changes of the product and requires comprehensive consideration of product functions, costs, and other factors. In some cases, post – processing processes can also be used to reduce the impact of sink marks. For example, sanding and polishing the surface of the plastic product can, to a certain extent, reduce the visual effect of sink marks. For products with extremely high appearance requirements, surface coating, film – pasting, etc. can also be used to cover the sink marks. However, these post – processing methods only cover the sink marks and cannot fundamentally solve the problem of sink mark generation.

Sink marks in plastics are a complex issue involving multiple technical links. Only by comprehensively considering and optimizing the entire process from material selection, product design, mold manufacturing to injection – molding process control can the problem of sink marks be effectively prevented and solved, improving the quality and production efficiency of plastic products. If you encounter sink mark problems in actual production, you are welcome to communicate further so as to analyze and solve them more pertinently.