Answer:

There is no absolute answer as to whether milling or turning is more difficult. The difficulty of the two varies depending on the specific application scenarios. Turning is mainly used to process rotary parts, and the operation relatively focuses on the rotation of the workpiece and the linear feed of the tool. Milling can process complex planes, contours, and three – dimensional surfaces, and it has higher requirements for tool path planning and multi – axis linkage control. From the perspective of beginner learning, the principles and operations of turning are relatively simple. However, when it comes to milling complex surfaces, the difficulty of programming and process planning in milling increases significantly.

Extended Knowledge Points:

As two basic and important processes in machining, milling and turning each have their unique technical characteristics and application scopes. The comparison of their difficulty cannot be simply determined and needs to be analyzed in depth from multiple dimensions.

I. Machining Objects and Process Complexity

Machining Objects and Processes of Turning

Turning is mainly used to process various rotary parts, such as shafts, discs, and sleeves. The machining process is that the machine tool spindle drives the workpiece to rotate, and the tool makes a linear feed movement parallel or perpendicular to the axis of the workpiece to complete operations such as external turning, internal turning, and thread turning. For simple rotary parts, the process route of turning is relatively straightforward. For example, when processing an ordinary stepped shaft, it only needs to successively turn out each shaft section according to the diameter size requirements through the transverse and longitudinal feeds of the tool. However, when it comes to rotary parts with complex shapes, such as shafts with special curved surface contours or high – precision threads, the difficulty of turning increases significantly. At this time, it is necessary to accurately calculate the tool path and control the cutting parameters to ensure the shape accuracy and surface quality of the curved surface, which requires high experience and skills from the operator.

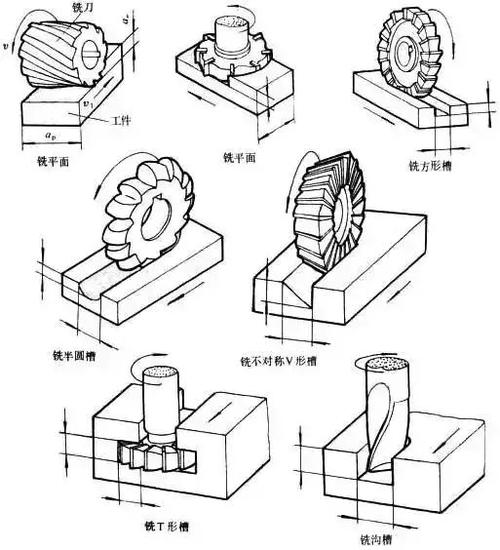

Machining Objects and Processes of Milling

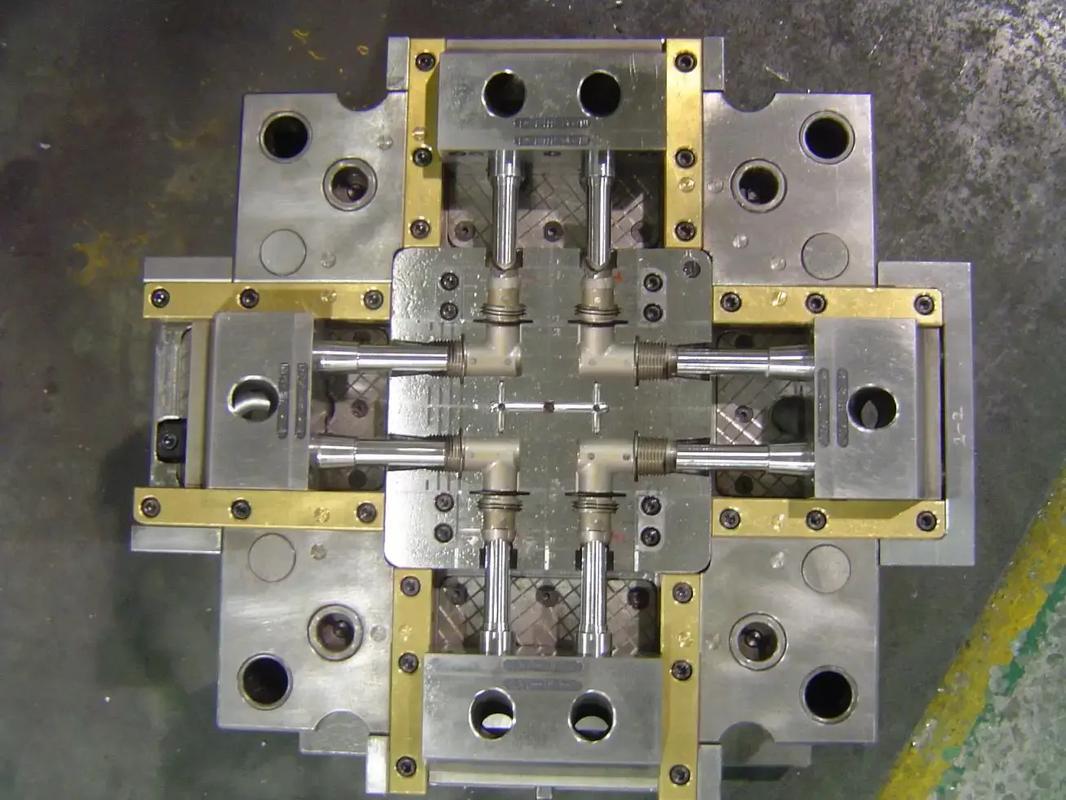

The machining scope of milling is wider. It can not only process planes and grooves but also, through multi – axis linkage, process complex two – dimensional and three – dimensional contours and surfaces, such as mold cavities and blade surfaces. During the milling process, the milling cutter makes a rotational main movement, and the workpiece or the milling cutter makes a feed movement. Compared with turning, the process planning of milling is more complex. Taking the processing of a complex mold cavity as an example, multiple factors need to be considered, such as the type of milling cutter (end mill, ball – nose mill, etc.), cutter diameter, cutting method (climb milling or conventional milling), and tool path. The process plans vary greatly according to different processing requirements and part shapes. Moreover, during the processing, multiple clamping and tool changes may be required, which all increase the difficulty of process planning. In addition, for multi – axis linkage milling, the movement coordination accuracy between each axis is extremely high, and any slight error may lead to the processed part not meeting the requirements.

II. Equipment Operation and Control Difficulty

Operation and Control of Turning Equipment

The operation interface and control system of a CNC lathe are relatively simple. During the operation, it mainly controls the rotation speed of the workpiece and the feed movement of the tool in the X and Z – axis directions. For beginners, it is relatively easy to understand and master the basic turning operations, such as setting the spindle speed, controlling the rapid positioning and cutting feed of the tool. However, when performing high – precision turning, the control requirements for the equipment become strict. It is necessary to precisely adjust the parameters of the machine tool, such as backlash compensation of the ball screw and tool wear compensation, to ensure machining accuracy. At the same time, when turning slender shafts and other easily deformed parts, special clamping methods and processing techniques need to be adopted to prevent the workpiece from deforming during processing, which tests the operator’s equipment operation experience and adaptability.

Operation and Control of Milling Equipment

The operation of CNC milling machines and machining centers is relatively complex. In addition to controlling the spindle speed and the linear movement of the tool in the X, Y, and Z – axis directions, it may also involve the control of rotating axes such as A, B, and C (in multi – axis machining centers). During multi – axis linkage processing, the operator needs to have a clear understanding of the movement relationships of each axis and be able to accurately set the linkage parameters of each axis to ensure that the tool processes along the predetermined path. Moreover, there are a wide variety of milling tools, and the installation and tool – setting methods of different types of tools are different, which increases the complexity of operation. During the processing, due to factors such as changes in milling force and tool wear, it is also necessary to monitor the processing status in real – time and adjust the cutting parameters in a timely manner, which puts forward higher requirements for the operator’s equipment operation skills and experience.

III. Programming Difficulty

Turning Programming

Turning programming is relatively simple, especially for regular rotary parts. When programming, it mainly focuses on the diameter change, length dimension of the workpiece, and parameters of the thread. The programming instructions used are relatively few, mainly including linear interpolation (G01), circular interpolation (G02, G03), thread cutting (G32), etc. For example, to write a simple external turning program, it only needs to set parameters such as the starting position of the tool, the cutting end – point position, and the cutting speed according to the diameter and length dimensions of the part. For manual programming, beginners can master the basic turning programming methods relatively quickly after a certain period of learning and practice. However, for rotary parts with complex shapes, such as turning non – circular curve contours, the programming difficulty increases significantly, and it may be necessary to use computer – aided programming software for programming.

Milling Programming

The difficulty of milling programming is usually higher than that of turning programming, especially when processing complex three – dimensional surfaces. Milling programming requires precise planning of the tool’s movement trajectory to ensure that the part shape that meets the requirements can be processed. More factors need to be considered during the programming process, such as tool selection, cutting layer thickness, and tool entry and exit methods. For two – dimensional contour milling, the programming difficulty is relatively low. However, for three – dimensional surface milling, even when using computer – aided programming software (such as UG, Mastercam, etc.), the programmer needs to have good spatial imagination ability and process knowledge to correctly set the processing parameters and tool path. In addition, in multi – axis linkage programming, the coordinate transformation and linkage relationships between each axis also need to be processed, further increasing the complexity and difficulty of programming.

IV. Difficulty in Handling Problems during the Machining Process

Problem – handling in the Turning Process

In turning, common problems include poor surface roughness of the workpiece, out – of – tolerance dimensional accuracy, and rapid tool wear. For example, when vibration marks appear on the workpiece surface, it may be caused by factors such as spindle run – out of the machine tool, loose tool installation, or unreasonable cutting parameters. The operator needs to have certain troubleshooting capabilities to accurately determine the cause of the problem and take corresponding solutions. For the deformation problem during the turning of slender shafts, it is necessary to solve it by adjusting the clamping method (such as using a center rest or a follow rest) and optimizing the cutting parameters, which requires the operator to have an in – depth understanding of the turning process and rich practical experience.

Problem – handling in the Milling Process

The problems faced during the milling process are more diverse. Due to the change of milling force and the complex movement of the tool, problems such as tool vibration, tool breakage, and uneven processing surface quality are likely to occur. When processing thin – walled parts, special attention needs to be paid to preventing the parts from deforming due to excessive cutting force. For example, when tool vibration occurs during milling, it may be caused by factors such as excessive tool overhang, excessive cutting parameters, or loose workpiece clamping. The operator needs to comprehensively consider various factors, gradually troubleshoot, and solve the problem. Moreover, in multi – axis milling, once a problem occurs, the difficulty of troubleshooting and solving is greater because it involves the movement of multiple axes and complex tool paths.

Milling and turning each have their own difficulty characteristics in different aspects. Turning is relatively easy when processing simple rotary parts, but the difficulty increases when dealing with parts with complex shapes and high – precision requirements. Milling has a wide processing range, complex processes and programming, and requires higher comprehensive capabilities from the operator. In practical applications, the specific difficulty also depends on factors such as the complexity of the processed parts, accuracy requirements, and equipment conditions. Whether it is milling or turning, continuous learning and practice are required to accumulate experience and master the corresponding processing technologies proficiently. If you want to have a deeper understanding of a specific aspect of milling or turning, you are welcome to communicate and discuss at any time.