Answer

CNC (Computer Numerical Control) is a technology that controls the movement of machine tools through computer programs, while machining is a processing method that removes materials through cutting, grinding, etc. to shape workpieces. The core difference is that CNC is an automated control means for achieving machining, while machining is a processing category that encompasses both traditional manual and CNC technologies.

Extended Answer

I. Definition and Scope: Differences in Essential Attributes

CNC (Computer Numerical Control)

Essence: A technical system that controls the movement of machine tool axes through computer programs (such as G – codes and M – codes).

Scope: It belongs to “automated control technology” and is a way to achieve machining. It relies on the cooperation between a numerical control system (such as Fanuc, Siemens) and machine tool hardware (such as servo motors, ball screws).

Machining

Essence: A processing technology that removes workpiece materials through physical means (tool cutting, grinding wheel grinding, etc.) to make them meet the designed shape, size, and precision.

Scope: It is a broad concept that includes traditional manual machining (such as ordinary lathes and milling machines, where the tool is controlled by an operator manually adjusting the handle) and numerical control machining (i.e., CNC machining).

II. Control Methods: Manual vs. Program – Automated

Program Control of CNC

Core Logic: Parameters such as machining paths, rotational speeds, and feed rates are written as digital programs, and the computer precisely controls the movement of the machine tool according to the program without the need for real – time manual intervention.

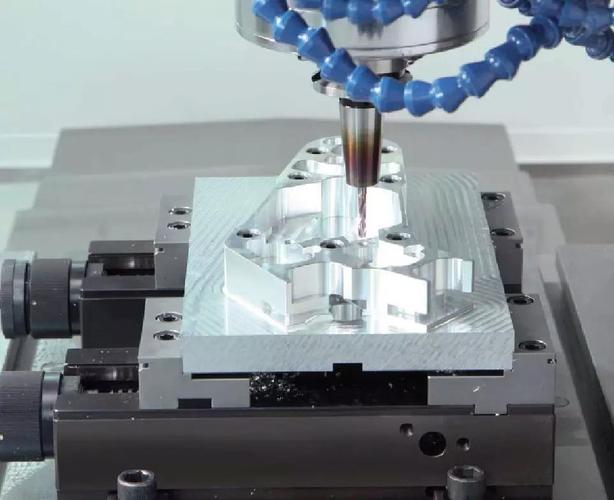

Example: When machining a complex – curved surface part, engineers generate a program through CAD/CAM software, and the CNC machine tool automatically completes the milling according to the code, with an error controllable at the 0.01mm level.

Manual Control of Traditional Machining

Core Logic: The operator controls the movement of the tool by manually adjusting the handles and knobs of the machine tool, and the machining precision depends on experience.

Example: When using an ordinary milling machine to machine a flat surface, the worker needs to visually adjust the position of the worktable by looking at the dial. The efficiency is low, and the precision fluctuates greatly (with an error of about 0.1mm or more).

III. Degree of Automation: From “Human – Dominated” to “Machine – Dominated”

High – degree Automation of CNC

Features: After a single clamping, multiple processes (such as milling, drilling, tapping) can be automatically completed, and it even supports unattended production (such as in combination with an industrial robot for loading and unloading).

Advantages: Reduces manual operation errors and is suitable for long – term continuous production (such as batch processing of automotive parts).

Manual Dependence of Traditional Machining

Features: Every operation (such as tool changing, tool setting, adjusting cutting parameters) requires manual intervention. The labor intensity is high, and it is difficult to ensure the consistency of batch workpieces.

Limitations: It is only suitable for small – batch and simple part processing (such as single – piece repair parts).

IV. Precision and Consistency: Differentiation at the Technical Level

High Precision and Stability of CNC

Precision Level: Conventional CNC machine tools can achieve an accuracy of ±0.05mm, and precision – type ones (such as mold machining centers) can reach ±0.005mm, which is suitable for precision parts in aerospace, medical equipment, etc.

Consistency: When machining repeatedly with the same program, the error of parts is extremely small, making it suitable for mass – producing standardized components (such as mobile phone casings, engine blocks).

Precision Fluctuation of Traditional Machining

Precision Level: It depends on the skills of the operator. A skilled worker can control the error to around ±0.1mm. It is difficult to meet the requirements for complex shapes or high – precision demands (such as precision gear processing).

Limitations: There may be dimensional deviations in different batches or within the same batch of parts, which is not suitable for scenarios with strict precision requirements.

V. Application Scenarios: The Choice between Batch – production and Complexity

Applicable Scenarios of CNC

Mass Production: Such as automotive wheels (thousands of pieces per batch), metal casings of 3C products. Programming can solve the batch – processing needs at one time, reducing the unit cost.

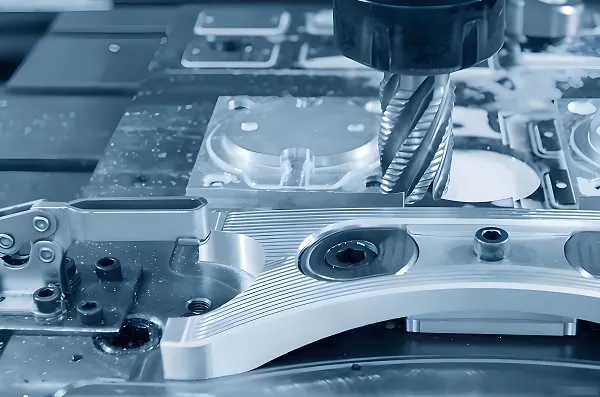

Complex Structures: Such as aerospace engine impellers (with complex curved surfaces and high – precision requirements), minimally invasive surgical instruments for medical devices. Traditional machining cannot achieve this, and multi – axis linkage of CNC (such as 5 – axis machining centers) is required.

Flexible Manufacturing: When changing products, only the program needs to be modified without readjusting the machine tool, which is suitable for multi – variety and small – batch production (such as customized parts).

Applicable Scenarios of Traditional Machining

Simple Parts: Such as ordinary bolts, flat parts. The processing steps are few, and manual operation is not less efficient than CNC (especially for single – piece production).

Repair and Prototyping: Such as temporary processing of agricultural machinery parts, production of hand – made tools. There is no need for programming, and direct manual operation is more flexible.

Low – cost Requirements: The equipment investment is low (an ordinary lathe costs about tens of thousands of yuan, while a CNC machine tool starts from hundreds of thousands of yuan), which is suitable for small – and – micro enterprises or short – term projects.

VI. Efficiency and Production Capacity: The Watershed of Large – scale Production

Efficiency Advantages of CNC

High – speed Machining: The spindle speed can reach 10,000 – 40,000rpm (such as high – speed machining centers). Coupled with an automatic tool – changing system, the auxiliary time is reduced.

Multi – process Integration: One CNC machining center can complete multiple processes such as milling, drilling, and boring, avoiding multiple workpiece clampings, and shortening the production cycle by 30% – 50%.

Efficiency Bottlenecks of Traditional Machining

Single – process Operation: For each process, manual tool changing and machine adjustment are required. For example, when processing a perforated plate, it needs to be transferred between a lathe and a drilling machine, resulting in low efficiency.

Speed Limitation: The spindle speed of ordinary machine tools is usually less than 3,000rpm, and the feed rate needs to be adjusted manually, making it difficult to increase production capacity.

VII. Programming and Technical Threshold: From “Experience” to “Digitalization”

Programming Requirements of CNC

Skill Requirements: One needs to master CAD/CAM software (such as UG, Mastercam) for 3D modeling and program generation, or manually write G – codes (such as linear interpolation G01, circular interpolation G02).

Learning Cost: It takes a novice several months to a year to master basic programming. For complex parts (such as impellers), a professional engineering team is required for collaboration.

Experience Dependence of Traditional Machining

Skill Requirements: The operator needs to master experience in machine tool structure, tool selection, cutting parameter optimization, etc. (such as adjusting the feed rate according to material hardness). It takes 3 – 5 years to train a skilled worker.

Knowledge System: It relies on “master – apprentice inheritance,” and the technical accumulation is difficult to standardize. The talent training cycle is long.

VIII. Cost Structure: The Trade – off between Initial Investment and Long – term Benefits

Cost Characteristics of CNC

High Initial Investment: A three – axis CNC machining center costs about 200,000 – 500,000 yuan, and a five – axis device can cost several million yuan. The supporting software and training costs are high.

Long – term Benefits: In mass production, the unit cost decreases as the output increases (for example, when producing 1,000 parts, the per – capita efficiency of CNC is 5 – 10 times that of traditional machining).

Cost Characteristics of Traditional Machining

Low Initial Investment: The cost of an ordinary machine tool is only tens of thousands of yuan, which is suitable for small enterprises with limited funds.

Long – term Cost Disadvantage: The labor cost is high (skilled workers are required), and the production capacity is low. In mass production, the unit cost exceeds that of CNC (for example, when producing more than 100 pieces).

IX. Technological Development and Integration: From Substitution to Complementation

The Upgrade of CNC over Traditional Machining

In the 1950s, CNC technology originated from the US military, initially used to solve the problem of machining complex parts, gradually replacing traditional machine tools in the fields of high – precision and mass production.

Complementary Scenarios of the Two

Small – batch + High – precision: Some enterprises adopt the model of “CNC machining key processes + traditional machine tools for simple processes” to balance cost and precision.

Special Processes: Fine processing such as manual grinding and polishing still requires manual operation, and CNC is difficult to completely replace.

X. Summary: How to Choose between CNC and Traditional Machining?

Choose CNC: When the part has high – precision requirements (below ±0.1mm), a complex structure, a large batch size (≥100 pieces), or requires automated production.

Choose Traditional Machining: When the part is simple, the batch size is small (≤10 pieces), the precision requirement is low, or the budget is limited and rapid production is urgently needed.

Essential Relationship: CNC is a technological upgrade of machining. The two are not opposed but a trade – off choice among “automation,” “precision,” and “cost” according to requirements.