Answer:

The strength of parts after CNC machining and forging cannot be simply generalized. Forging improves the internal structure of metals through plastic deformation, enhancing strength and toughness, and is suitable for parts subject to high loads. CNC machining is a material – removal forming process, and the strength of parts mainly depends on the performance of the raw materials. Appropriate heat treatment can also increase the strength. In simple terms, for parts made of the same material, those subject to complex and high stresses have better strength after forging. For parts with high requirements for shape accuracy and uniform stress, CNC machining combined with heat treatment can also meet the strength requirements.

Professional Extension

I. The Underlying Influence of Processing Principles on Part Strength

Forging uses impact force or pressure to cause plastic deformation of metal billets, changing their shape, size, and internal structural properties. During forging, metal grains are refined, internal looseness, pores, and other defects are compacted, and a fiber streamline structure is formed. When the part is under stress, the streamline direction is consistent with the main stress direction, significantly improving strength and fatigue resistance. For example, for the crankshaft of an automobile engine, forging can make the metal fibers distribute continuously along the crankshaft contour, enhancing its reliability under complex alternating loads.

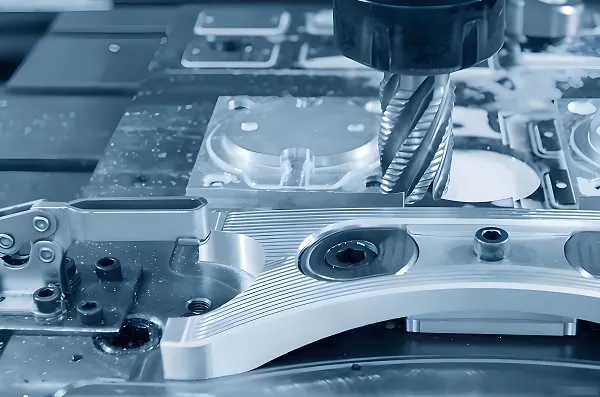

CNC machining is based on the material – removal principle. The raw materials are processed into the target shape through tool cutting. This process does not change the original structural state of the metal material, and the strength of the part mainly depends on the performance of the raw material itself and subsequent heat – treatment processes. For example, a part machined from an aluminum – alloy bar through CNC milling has a strength basically equivalent to the initial strength of the bar. To improve the strength, heat – treatment processes such as solution treatment and aging treatment are required.

II. Material Property Changes and Strength Enhancement Mechanisms

During forging, metals undergo dynamic recrystallization and work hardening. Dynamic recrystallization refines the grains, increasing the number of grain boundaries. Grain boundaries impede crack propagation, thereby improving the material’s strength. Work hardening increases the resistance to dislocation movement through dislocation multiplication and entanglement, increasing the strength and hardness of the material. For example, in the forging of titanium alloys, the tensile strength can be increased by 20% – 30% after multiple forging passes.

If CNC – machined parts do not undergo heat treatment, the material properties change little. However, through subsequent heat treatment, for example, quenching can enable steel parts to obtain a martensite structure, greatly increasing hardness and strength; tempering relieves quenching stress and adjusts the balance between strength and toughness. However, the structural uniformity of CNC – machined parts is limited by the raw materials. Compared with forged parts, their internal structural uniformity is poor, and they are more likely to fail in local stress – concentration areas.

III. The Relationship between Defect Control in the Process and Strength

The forging process requires strict control of process parameters; otherwise, defects such as folds, cracks, and incomplete filling may occur. However, as long as the process is reasonable, forging can effectively eliminate internal looseness and pores in the metal and improve its density. For example, for large – scale marine crankshafts, forging with a ten – thousand – ton press can reduce internal defects, and the density can approach 100%, improving the overall strength.

During the CNC – machining process, the cutting force may cause residual stress in the part. If the residual stress distribution is unreasonable, it will reduce the fatigue strength of the part. In addition, problems such as tool wear and improper cutting parameters during the processing may cause surface – processing defects, such as tool marks and micro – cracks. These defects will become crack sources when the part is under stress, reducing the part’s strength and service life.

IV. The Adaptability of Application Scenarios to Strength Requirements

In fields such as aerospace and energy power, key stressed components such as aircraft landing gears and steam – turbine rotors, which need to withstand high loads and complex stresses, are mostly produced by forging to ensure that the parts have sufficient strength and reliability. In industries such as electronic equipment and medical devices, the parts are subject to relatively low stress, but have high requirements for shape accuracy and surface quality. CNC machining is often used. Through reasonable material selection and heat treatment, the strength requirements during use can also be met. For example, for mobile – phone casings, CNC – machined aluminum alloys, after anodizing treatment, can not only ensure the appearance quality but also withstand minor impacts and extrusions during daily use.