In the field of mechanical engineering, from micro electronic components to large industrial equipment, threads serve as the fundamental structure for connection and transmission, and the machining accuracy directly affects the performance and reliability of equipment. Compared with traditional tapping, thread milling has become the preferred solution for thread machining of medium-to-large workpieces and complex materials due to its flexibility and precision. The following deeply analyzes the core value of this CNC machining process from the dimensions of technical principles, application scenarios, and process advantages.

1.The Technical Essence of Thread Milling: The Art of Spiral Forming Driven by CNC

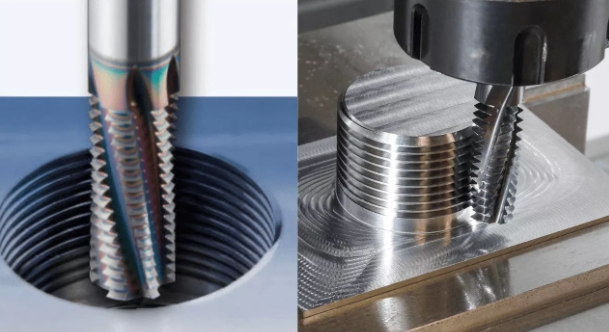

Thread milling is a subtractive manufacturing process based on CNC (Computer Numerical Control) systems. It uses special milling cutters to cut workpieces along a spiral path to form precise thread structures. Different from traditional tapping, which relies on taps for direct extrusion forming, the core of the milling process lies in three-axis control (three-axis simultaneous motion control): the X/Y axis movement determines the thread diameter, the Z axis movement controls the pitch, and the tool removes materials layer by layer along the spiral trajectory to finally construct a thread profile that meets the design requirements.

The unique advantages of this process include:

- Geometric Adaptability: The same tool can be programmed to machine internal/external threads of different diameters and pitches, even achieving high-precision machining on thin-walled parts or large-diameter workpieces;

- Material Compatibility: It can complete thread forming for materials from aluminum alloy, stainless steel to high-strength materials like titanium alloy, especially suitable for difficult-to-machine materials such as tool steel with hardness >45 HRC;

- Precision Advantage: The micron-level control capability of the CNC system enables the surface roughness of threads to reach below Ra1.6, with the pitch circle diameter tolerance controlled within ±0.02mm.

2.Tool System: The “Soul Tool” of Thread Milling

The design of thread milling cutters directly determines machining efficiency and quality, which can be divided into three categories by structure:

-

Groove Design-Driven Type

- Straight Flute Milling Cutters: The cutting edges are arranged in a straight line, suitable for easy-to-cut materials like aluminum and ABS. The chip removal path is direct, but the cutting resistance is relatively large;

- Spiral Flute Milling Cutters: The cutting edges have a spiral angle of 15°-30°, and chips are discharged more smoothly along the spiral grooves, which can increase the cutting speed by more than 30% and obtain a smoother surface (Ra3.2-Ra1.6).

-

Cutting Efficiency-Optimized Type

- Single-Form Milling Cutters: Single-point cutting, high flexibility, suitable for small-batch and multi-specification internal thread machining, but the single-tooth cutting speed is slow;

- Single-Profile Milling Cutters: Multiple edges cut simultaneously to complete thread forming in one pass, with an efficiency 50% higher than single-form cutters, but only suitable for fixed specifications (such as M6×1.0).

-

Bulk Production-Dedicated Type

- Multi-Form Milling Cutters: Through the design of axial pitch matching, they can cut multiple thread grooves simultaneously, especially suitable for mass production of the same specification threads, with a machining efficiency 2-3 times higher than single-edge tools.

3.Process Comparison: Thread Milling VS Tapping, How to Choose?

| Comparison Dimension | Thread Milling | Tapping Process |

|---|---|---|

| Core Principle | CNC spiral interpolation, single-point tool cutting layer by layer | Tap extrusion forming, tool shape directly matches the thread |

| Flexibility | One tool can machine multiple specifications, supporting left/right threads | Need to replace special taps, limited by specifications |

| Material Adaptability | Can machine hard alloys, titanium alloys, nickel-based alloys, etc. | Only suitable for soft materials like aluminum alloy and low-carbon steel |

| Production Efficiency | Slower for small holes (10-15 seconds/hole), better for large sizes | Fast for small holes (2-8 seconds/hole), efficient for mass production |

| Precision Control | High surface finish, tolerance control ±0.02mm | Precision depends on tap quality, with higher surface roughness |

| Cost-Effectiveness | Suitable for small-to-medium batches and high-precision requirements | Lower cost for mass production of standard threads |

Application Scenario Suggestions: When machining sealing threads for titanium alloy aerospace components, micro-precision threads for medical devices, or variable-diameter threads on stainless steel pipes, thread milling is a better choice; while for machining standard bolt holes in automotive parts, the tapping process is more common due to its efficiency and cost advantages.

4.Practical Rules for Efficient Milling: Full-Process Optimization from Programming to Operation

-

Golden Rules for Parameter Setting

- Cutting Speed: When using cemented carbide tools to machine steel, it is recommended to control at 80-120m/min, and reduce to 40-60m/min for titanium alloys;

- Feed Rate: 0.05-0.1mm feed per tooth for single-edge milling cutters, which can be appropriately increased for multi-edge cutters, but avoid cumulative cutting heat.

-

Key Points for Tool and Workpiece Clamping

- When selecting spiral flute milling cutters, preferentially choose coated tools (such as TiAlN coating) to improve wear resistance;

- The clamping force of workpieces should be uniform, and elastic fixtures can be used for thin-walled parts to avoid deformation.

-

Programming and Process Optimization

- Adopt the tool path of “arc entry-spiral cutting-arc exit” to reduce axial impact;

- Add a counterbore of 0.5-1 times the pitch at the end of internal threads, and machine a 45° chamfer at the end of external threads to improve assembly compatibility.

5.Thread Milling in the Industry 4.0 Era: From Technology to Solutions

Under the trend of intelligent manufacturing, thread milling is deeply integrated with digital design (CAD/CAM) and intelligent machine tools. For example, advanced manufacturing service providers like Xiamen Goldcattle achieve full-process automation from drawings to finished products through multi-axis CNC equipment and Design for Manufacturability (DFM) optimization—after customers upload 3D models, the system can automatically generate milling programs, simultaneously complete tool path planning and cost accounting, shortening the traditional preparation work that takes hours to minutes.

For fields with harsh requirements for thread accuracy, such as aerospace and medical devices, thread milling is not only a machining process but also a bridge connecting design creativity and engineering realization. When precision threads become the key nodes of equipment reliability, choosing a professional milling solution often means the leap from “qualified manufacturing” to “excellent manufacturing”.

Conclusion: Thread milling occupies an irreplaceable position in the field of high-end manufacturing with its technical flexibility and precision advantages. Whether facing the machining challenges of complex materials or the design needs of customized threads, this process continues to break through the boundaries of traditional machining, injecting more precise “connecting power” into modern industry.