I. What is Carbon Steel?

Carbon steel, the full name is carbon structural steel, is an iron-carbon alloy with a carbon mass fraction ranging from 0.0218% to 2.11%, and no alloying elements are deliberately added. Due to its simple smelting process, affordable cost, and performance that can meet the standards for general engineering components, mechanical parts, and tools, it is widely used in numerous fields.

According to different classification criteria, carbon steel can be divided into various types. Classified by carbon content, it can be divided into low-carbon steel (carbon mass fraction < 0.25%), medium-carbon steel (carbon mass fraction = 0.25% – 0.6%), and high-carbon steel (carbon mass fraction > 0.6%); by smelting method, it can be divided into open-hearth steel and converter steel; by smelting quality, it can be further divided into ordinary carbon steel (with higher phosphorus and sulfur content), high-quality carbon steel (with lower phosphorus and sulfur content), high-grade high-quality steel (with even lower phosphorus and sulfur content), and special-grade high-quality steel. In practical applications, classification by use is the most common, specifically divided into carbon structural steel, carbon tool steel, and free-cutting structural steel.

II. Characteristics of Carbon Steel CNC Machined Parts

2.1 Mechanical Properties

The mechanical properties of carbon steel are closely related to its carbon content. Low-carbon steel has good plasticity and toughness, but relatively low strength. For example, common Q195 and Q215 steels are often rolled into thin plates, steel bars, and welded steel pipes, and are used in structures such as bridges and buildings. They are also used to manufacture common rivets, screws, nuts, and other parts. Medium-carbon steel has a more balanced comprehensive performance, with moderate strength, plasticity, and toughness. The 45# steel, for instance, is widely used in the field of mechanical manufacturing and can be used to manufacture shafts, gears, and other parts. High-carbon steel has high strength and hardness, but poor plasticity and toughness, and is often used to manufacture tools, molds, etc.

2.2 Machinability

Carbon steel has good machinability. Compared with some special alloys, its hardness is moderate. During CNC machining, it causes relatively little wear on the cutting tools, enabling efficient machining operations such as cutting, drilling, and milling. At the same time, carbon steel has good thermal conductivity. The heat generated during machining can be dissipated quickly, which helps to maintain machining accuracy and reduce errors caused by workpiece thermal deformation.

2.3 Corrosion Resistance

Generally, the corrosion resistance of carbon steel is not ideal, especially in harsh environments such as humidity, acids, and alkalis, it is prone to rust. To improve its corrosion resistance, surface treatment processes such as galvanizing, painting, and passivation are often required.

III. How to Perform CNC Machining on Carbon Steel?

3.1 Preparation before Machining

Before machining, a three-dimensional model needs to be constructed using computer-aided design (CAD) software according to the part design drawings, and then a numerical control machining program is generated with the help of computer-aided manufacturing (CAM) software. At the same time, suitable carbon steel materials should be selected. According to the usage requirements of the parts, the specific grade of carbon steel is determined. For example, low-carbon steel can be selected for parts that require good plasticity, and medium-carbon steel or high-carbon steel can be chosen for parts that require higher strength. In addition, appropriate cutting tools need to be prepared. Commonly used cutting tools for machining carbon steel include cemented carbide tools and high-speed steel tools. Different types and specifications of tools should be selected according to different machining processes (such as rough machining, finish machining) and machining parts (such as planes, holes).

3.2 Machining Process

The prepared carbon steel material is clamped on the CNC machine tool. It is essential to ensure that the clamping is firm and the position is accurate to avoid displacement during machining, which may affect the machining accuracy. According to the generated numerical control program, the machine tool controls the cutting tool to machine the workpiece. During the machining process, cutting parameters, including spindle speed, feed rate, and cutting depth, need to be precisely controlled. For example, for ordinary carbon steel, the spindle speed is generally controlled at 800 – 1500 revolutions per minute, the feed rate at 50 – 150 mm/min, and the cutting depth at 1 – 5 mm. Meanwhile, the rational use of coolant can effectively reduce the cutting temperature, reduce tool wear, and improve the surface quality of the machining. Common coolants include emulsions, cutting oils, and water, and the selection should be based on specific machining processes and workpiece materials.

3.3 Post-processing

After machining is completed, the parts are cleaned to remove residual cutting fluid, iron filings, and other impurities on the surface. Then, according to the quality standards of the parts, measuring tools (such as calipers, micrometers, coordinate measuring machines, etc.) are used to detect the dimensional accuracy, shape accuracy, and position accuracy of the parts to ensure that the parts meet the design requirements. For some parts with extremely high precision requirements, subsequent finishing processes such as grinding and polishing may be required.

IV. Characteristics Table of CNC Carbon Steel Parts

V. How to Customize CNC Carbon Steel Parts?

5.1 Clarify Requirements

Communicate fully with customers to understand in detail the usage scenarios, functional requirements, precision standards, appearance requirements, and required quantity of the parts. Customers are required to provide detailed part design drawings. If there are no drawings, a professional design team can design according to customer requirements.

5.2 Select a Machining Manufacturer

Choose a CNC machining manufacturer with rich experience, advanced equipment, and a professional technical team. Check the manufacturer’s past cases and customer reviews to evaluate its machining capabilities and quality control levels. It is advisable to conduct on-site inspections of the manufacturer to understand its production scale, equipment status, and management level.

5.3 Quotation and Order Placement

The machining manufacturer quotes according to factors such as the complexity of the parts, material costs, machining processes, and quantity. After the customer approves the quotation, both parties sign a machining contract, clearly defining machining requirements, delivery time, price, payment method, and other terms. After the customer pays the advance payment, the manufacturer officially arranges production.

VI. Machining Process of CNC Carbon Steel Parts

6.1 Drawing Design and Review

Design the drawings according to customer requirements. After the design is completed, organize professionals to review the drawings to ensure that the dimensional markings on the drawings are accurate and the technical requirements are clear and reasonable, avoiding machining errors caused by drawing problems.

6.2 Material Procurement and Inspection

Purchase suitable carbon steel materials according to the requirements of the drawings. Conduct strict inspections on the purchased materials, checking whether the specifications, hardness, chemical composition, etc. of the materials meet the standards to ensure the quality of the materials.

6.3 CNC Machining

Perform machining on the CNC machine tool according to the established machining process and numerical control program. Monitor the machining status in real-time during the machining process and adjust the parameters in a timely manner to ensure machining accuracy and quality.

6.4 Quality Inspection

Conduct a comprehensive quality inspection on the machined parts. The inspection items include dimensional accuracy, shape accuracy, position accuracy, surface roughness, and hardness, etc., to ensure that the parts meet the design and customer requirements.

6.5 Surface Treatment

Select appropriate surface treatment processes, such as galvanizing, chrome plating, painting, passivation, etc., according to the usage environment of the parts and the customer’s requirements for appearance, to improve the corrosion resistance and aesthetics of the parts.

6.6 Packaging and Delivery

Package the parts that have passed the inspection and completed the surface treatment. Select appropriate packaging materials to ensure that the parts are not damaged during transportation. Deliver the parts to the customer according to the delivery time and method stipulated in the contract.

VII. Machining Technologies of CNC Carbon Steel Parts

7.1 High-precision Machining Technology

To meet the machining requirements of some parts with extremely high precision requirements, advanced CNC control systems and high-precision machine tools are adopted, combined with optimized machining processes, to achieve machining with micron-level or even higher precision. For example, in the machining of some carbon steel parts in the aerospace field, through the use of high-precision grinding processes and on-line detection technologies, the dimensional accuracy of the parts can be controlled within ±0.001mm.

7.2 High-speed Machining Technology

High-speed machining technology can significantly improve machining efficiency and reduce production costs. By increasing the spindle speed and feed rate of the machine tool, the machining time can be greatly shortened while ensuring machining quality. When machining carbon steel parts, the high-speed milling technology is used, and the spindle speed can reach more than 20,000 revolutions per minute, and the feed rate can reach several meters per minute, effectively improving the machining efficiency.

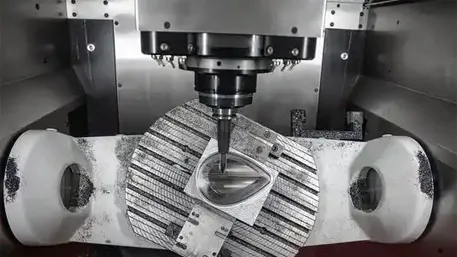

7.3 Multi-axis Linkage Machining Technology

Multi-axis linkage machining technology can realize the machining of complex-shaped parts. Through the coordinated movement of multiple axes, the cutting tool can cut the workpiece at various angles and postures. For some carbon steel parts with complex curved surfaces, the five-axis linkage machining technology is used, which can complete the machining of multiple surfaces at one clamping, reduce the number of clamping times, and improve machining accuracy and surface quality.

VIII. Machining Equipment for CNC Carbon Steel Parts

8.1 CNC Machining Centers

CNC machining centers are comprehensive numerical control machining equipment with a wide range of functions. They integrate multiple machining functions such as milling, boring, drilling, and tapping, and can achieve automatic tool change and continuous multi-process machining through programming. Machining centers have high precision and stability and are suitable for machining various carbon steel parts with complex shapes and high precision requirements. Common machining centers include vertical machining centers and horizontal machining centers, which are selected according to the shape and machining requirements of the parts.

8.2 CNC Lathes

CNC lathes are mainly used for machining rotary parts, such as shaft parts and disc parts. They control the movement trajectory of the cutting tool through the numerical control system to achieve turning machining of the workpiece. CNC lathes have the advantages of high machining accuracy, high production efficiency, and high degree of automation, and can meet the turning machining requirements of carbon steel parts with different precision requirements. Some advanced CNC lathes also have the function of turning-milling compound machining, which can complete multiple machining processes in one clamping.

8.3 CNC Grinding Machines

CNC grinding machines are used for grinding carbon steel parts to obtain high-precision dimensions and surface quality. Grinding can remove tiny defects and allowances on the surface of the parts, improving the shape accuracy and surface roughness of the parts. According to different grinding methods, CNC grinding machines can be divided into surface grinding machines, cylindrical grinding machines, internal grinding machines, etc., which are selected according to the machining parts and requirements of the parts.

IX. Application Fields of CNC Carbon Steel Parts

9.1 Mechanical Manufacturing

In the field of mechanical manufacturing, CNC carbon steel parts are widely used in the manufacturing of various mechanical equipment, such as machine tools, engines, reducers, etc. For example, many parts of machine tools, such as machine tool beds, guide rails, gears, etc., are made of carbon steel materials and manufactured by CNC machining to ensure the precision and mechanical properties of the parts.

9.2 Automobile Manufacturing

In automobile manufacturing, a large number of CNC carbon steel parts are used, such as engine crankshafts, connecting rods, gears, and various brackets and steering knuckles of the automobile chassis. These parts have high requirements for strength, precision, and reliability, and CNC machining can meet the strict standards of automobile manufacturing.

9.3 Construction Engineering

In the field of construction engineering, CNC machined parts made of carbon steel materials are often used in building structural components and construction equipment. For example, many parts such as connectors, bolts, nuts in building steel structures, and various components in construction equipment are made of carbon steel through CNC machining.

9.4 Hardware Tools

For various hardware tools, such as wrenches, screwdrivers, pliers, etc., their main bodies are usually made of carbon steel and obtain precise shapes and dimensions through CNC machining to ensure the performance and quality of the tools.

X. Customization of CNC Carbon Steel Parts

10.1 Customization Advantages

Customizing CNC carbon steel parts can achieve personalized production according to the unique needs of customers, meeting the special requirements of parts in different industries and scenarios. Through customization, precise control can be achieved in material selection, dimensional accuracy, shape design, surface treatment, etc., thereby improving the adaptability and performance of the parts. At the same time, customized production can effectively avoid possible performance redundancy or deficiencies of general-purpose parts, reduce costs, and improve production efficiency.

10.2 Customization Process

The customization process of CNC carbon steel parts generally includes links such as demand communication, drawing design, process planning, machining and manufacturing, quality inspection, surface treatment, and packaging and delivery. In the demand communication stage, communicate deeply with customers to clarify various requirements of the parts; in the drawing design stage, draw detailed design drawings according to the requirements; the process planning determines the machining process and parameters; machining and manufacturing are carried out according to the plan; quality inspection ensures that the quality of the parts meets the standards; surface treatment improves the corrosion resistance and appearance of the parts; finally, the parts are packaged and delivered to the customer.

XI. Common Problems of CNC Carbon Steel Parts

11.1 Dimensional Deviation

During the machining process, dimensional deviation of parts may occur due to reasons such as tool wear, unreasonable cutting parameters, and decline in machine tool accuracy. Solutions include regularly checking and replacing cutting tools, optimizing cutting parameters, and regularly detecting and maintaining the accuracy of the machine tool.

11.2 Surface Quality Problems

Problems such as non-compliance with surface roughness requirements, scratches, and burns may occur. This may be caused by reasons such as too high cutting speed, too large feed rate, improper use of coolant, or wear of the tool edge. Improvement can be achieved by adjusting cutting parameters, reasonably selecting and using coolant, and replacing cutting tools in a timely manner.

11.3 Deformation Problems

Cutting forces, thermal stresses, etc. generated during the machining process may cause part deformation. Deformation can be reduced by optimizing the machining process, such as adopting a reasonable machining sequence, multi-pass cutting, and increasing support. For deformed parts, correction processes can be used for repair.

XII. Marketing Speech for Message Consultation

If you have any questions or needs regarding the customization of CNC carbon steel parts, please feel free to leave us a message for consultation. We have a professional technical team that can provide you with a one-stop solution from design to machining. Whether you need single-piece customization or mass production, we can meet your requirements with an efficient production process, strict quality control, and reasonable prices. Leave a message now, and let’s work together to create the highest-quality CNC carbon steel parts for you.