In the field of modern manufacturing precision machining, CNC milling and turning are like two “shape master sculptors”, each specializing in different technological languages. When an engineer faces a part drawing, the choice of process often determines the balance of cost, precision, and efficiency. This article will comprehensively analyze these two core machining processes from technical principles, application scenarios to selection logic.

Ⅰ.Process Essence: Movement Modes Determine “Specialized Fields”

CNC Milling: The ‘Multi-Dimensional Dance’ of Cutting Tools

The core of milling is fixing the workpiece while the cutting tool rotates and moves multi-axially. Imagine a five-axis milling machine where the spindle drives multi-point cutting tools like end mills and ball nose cutters, moving translationally along the X/Y/Z axes while swinging via A/B axes for multi-angle cutting. This model of “the tool rotating around the workpiece” excels at sculpting complex surfaces, grooves, and multi-planar features, such as the curved casings of aerospace engines or the bionic structures of medical joint prostheses. A typical case: A medical enterprise used five-axis milling to machine a titanium alloy knee prosthesis, importing 3D models to complete 27 complex surface processes in one clamping, achieving a precision of ±0.01mm.

The core of milling is fixing the workpiece while the cutting tool rotates and moves multi-axially. Imagine a five-axis milling machine where the spindle drives multi-point cutting tools like end mills and ball nose cutters, moving translationally along the X/Y/Z axes while swinging via A/B axes for multi-angle cutting. This model of “the tool rotating around the workpiece” excels at sculpting complex surfaces, grooves, and multi-planar features, such as the curved casings of aerospace engines or the bionic structures of medical joint prostheses. A typical case: A medical enterprise used five-axis milling to machine a titanium alloy knee prosthesis, importing 3D models to complete 27 complex surface processes in one clamping, achieving a precision of ±0.01mm.

CNC Turning: The ‘Rotational Ballet’ of Workpieces

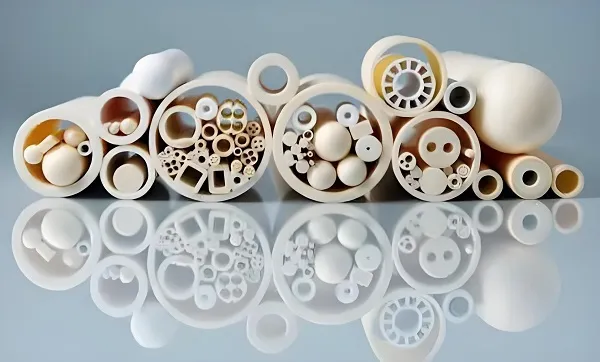

Turning follows the logic of high-speed workpiece rotation with single-point tool cutting. The chuck clamps the bar stock (rotating at up to 8,000rpm), and the tool feeds along the X/Z axes to remove material like sharpening a pencil, specializing in manufacturing axisymmetric parts—shafts, sleeves, bolts, etc. For example, crankshafts in automotive engines can achieve a roundness precision of 0.005mm and surface roughness of Ra0.4μm through turning, advantages that milling struggles to achieve at low cost.

Turning follows the logic of high-speed workpiece rotation with single-point tool cutting. The chuck clamps the bar stock (rotating at up to 8,000rpm), and the tool feeds along the X/Z axes to remove material like sharpening a pencil, specializing in manufacturing axisymmetric parts—shafts, sleeves, bolts, etc. For example, crankshafts in automotive engines can achieve a roundness precision of 0.005mm and surface roughness of Ra0.4μm through turning, advantages that milling struggles to achieve at low cost.

Ⅱ.Technical Characteristics: The “Adaptation Code” from Equipment to Materials

| Dimension | CNC Milling | CNC Turning |

|---|---|---|

| Core Movement | Multi-axial tool linkage (3-5 axes), suitable for asymmetric complex shapes | Workpiece rotation + linear tool feed, specializing in axisymmetric |

| Tool Types | Multi-point cutting tools (end mills, drills, thread mills, etc.) | Single-point cutting tools (external turning tools, boring tools, thread tools, etc.) |

| Material Compatibility | Metals (aluminum/titanium/steel), plastics, composite materials (carbon fiber), ceramics | Metals (steel/copper/aluminum), plastics, limited wood/composite materials |

| Precision Advantages | Complex surface precision ±0.02mm, multi-plane parallelism 0.01mm/m | Rotational part roundness 0.003mm, coaxiality 0.005mm |

| Efficiency Advantages | Rapid prototyping for small-batch complex parts (e.g., 3D printing mold machining) | High-efficiency mass production of cylindrical parts (e.g., 10 automotive bolts per minute) |

Equipment Differences: Milling machines can hold 20-30 tools in their tool magazines, suitable for frequent machining action changes; turning machines typically equip turrets with 6-12 specialized tools, with live tool turrets enabling auxiliary functions like drilling and slot milling (e.g., Swiss-type sliding headstock lathes improve material utilization by 40% when machining slender shafts).

Ⅲ.Industry Applications: “Precision Partners” with Distinct Roles

CNC Milling’s ‘Complex Battlefield’

- Aerospace: Airframe structural components (e.g., multi-hole weight-reducing designs for titanium alloy wing ribs), complex engine cavities (one-step five-axis milling)

- Medical Devices: Surgical instruments (e.g., multi-curved ergonomic designs for arthroscope handles), implants (precision machining of customized 3D printing molds)

- Electronic Manufacturing: Mobile phone mid-frames (one-piece aluminum alloy forming with curved chamfers and heat-dissipating slots), PCB precision brackets (0.1mm-level hole positioning accuracy)

CNC Turning’s ‘Symmetric Kingdom’

- Automotive Industry: Engine shafts (roundness 0.005mm for Φ50mm titanium alloy shafts), piston pins (surface hardness HRC55, roughness Ra0.2μm)

- Petroleum Equipment: High-pressure pipeline joints (corrosion-resistant nickel-based alloys with sealing surface flatness 0.002mm after turning)

- Precision Instruments: Watch gear shafts (coaxiality 0.001mm for Φ1.5mm stainless steel shafts, requiring Swiss-type lathe machining)

Ⅳ.Selection Logic: The Part’s “Requirement List” Determines the Optimal Solution

-

Shape Priority Principle

- Asymmetric/multi-curved parts with side holes (e.g., mold cores) → Milling

- Cylindrical/disk-shaped parts with concentric threads (e.g., flanges) → Turning

Case: A drone customer originally used milling for Φ10mm carbon fiber drive shafts, incurring high costs and insufficient concentricity. Switching to sliding headstock turning improved efficiency by 300% and reduced defect rates from 8% to 1%.

-

Precision and Surface Requirements

- Multi-plane parallelism, complex contour fitting → Milling (e.g., multi-station positioning surfaces for medical devices)

- Rotational part roundness, coaxiality, mirror surfaces → Turning (e.g., aluminum alloy lens barrels for optical lenses)

-

Production Scale and Cost

- Small-batch complex parts (1-100 pieces): Milling offers flexibility with low programming cost allocation

- Mass-produced standard parts (1,000+ pieces): Turning provides efficiency advantages in tool wear and labor costs

Data: For the same Φ30mm aluminum bolt, turning costs ¥0.8 per piece, while milling costs ¥3.2 (including multiple tool changes and positioning time).

-

Material Machining Characteristics

- Difficult-to-machine materials (titanium alloys, superalloys): Turning’s single-point cutting distributes heat more evenly, extending tool life by 20%

- Brittle materials (ceramics, fiberglass): Milling’s multi-blade micro-cutting reduces chipping risks

Ⅴ.Future Trends: Turn-Mill Composite—The “All-Round Craftsman” Breaking Boundaries

With the popularity of high-end equipment from DMG MORI and Mazak, turn-mill composite machining has become mainstream. For example, an aerospace component is first turned to rapidly form the shaft body, then its side hexagonal grooves are milled via a live tool turret without secondary clamping, improving precision by 70%. Manufacturing service providers like Xiamen Goldcattle have realized “one-stop” solutions: 5-axis milling for complex surfaces, CNC turning for rotational parts, combined with an online quotation system (30-minute accurate quotes) and 24-hour prototyping, allowing engineers to focus on product innovation without worrying about process details.

Conclusion: Empowering Design with Processes

CNC milling and turning are not opposites but “complementary skills” in precision manufacturing. The former is the “breaker of complex shapes,” while the latter is the “guardian of symmetric precision.” When engineers master the technical languages of both, they can select the optimal path based on the part’s “genetics” (shape, material, precision). With support from professional manufacturing platforms like Xiamen Goldcattle, this selection is becoming smarter—upload a 3D drawing, and the system automatically matches the process, transforming technical advantages into tangible production efficiency.

The next time you face a part design, remember: Milling gives parts “personality,” turning gives them “generality,” and the best manufacturing solution always lies in the insight into details.