I. Definition of CNC Multi – axis Machining

CNC multi – axis machining, namely Computer Numerical Control Multi – axis Machining, is an advanced CNC machining technology that adds rotation axes (such as A, B, C axes, rotating around the X, Y, Z axes respectively) based on three – axis CNC machining (X, Y, Z linear axes). It enables the coordinated movement of multiple axes. Through the precise control of multiple axes by the CNC system, the cutting tool can move along complex trajectories in three – dimensional space to complete the machining of complex workpieces such as curved surfaces and special – shaped structures. Compared with traditional three – axis machining, multi – axis machining can reduce the number of clamping times, avoid machining blind spots, and significantly improve the machining accuracy and surface quality of complex parts. It is especially suitable for the manufacturing of parts with features such as free – form surfaces, undercut structures, and complex cavities.

II. Key Points of CNC Multi – axis Machining Technology

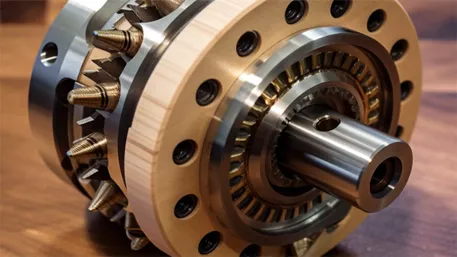

Equipment Selection and Axis Configuration

Select appropriate multi – axis machining equipment according to processing requirements. Common machine tools include four – axis (three linear axes + one rotation axis), five – axis (three linear axes + two rotation axes), or even machines with more axes. Different axis configurations determine the complexity and flexibility of machining. For example, five – axis simultaneous machining can adjust the tool attitude in real – time, making it more suitable for the machining of complex curved surfaces such as aero – engine blades. Four – axis equipment is often used for the side – profile machining of simple rotary parts.

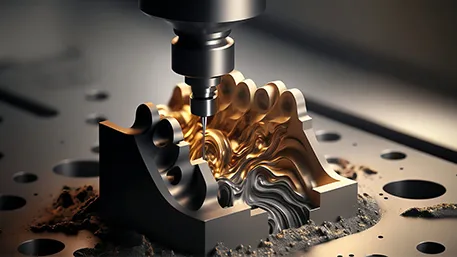

Tool Path Planning and Programming

Use advanced CAM software (such as UG, MasterCAM, PowerMill) for tool – path planning. Interference problems caused by the movement of rotation axes need to be fully considered. Special path strategies such as spiral milling and trochoidal milling are adopted to optimize the cutting angle and step – over. When programming, the curvature changes of the curved surface should be taken into account. By adjusting the tool – axis vector, the cutting force can be ensured to be uniform, reducing tool wear and vibration.

Cutting Parameter Optimization

Cutting parameters have a significant impact on machining quality in multi – axis machining. The cutting speed, feed rate, and cutting depth need to be adjusted dynamically according to material properties and tool types. For example, when machining high – hardness materials such as titanium alloys, the cutting speed is reduced to reduce tool thermal wear. When machining soft materials such as aluminum alloys, the feed rate is appropriately increased to improve efficiency. At the same time, the Constant Cutting Volume (Ctv) control strategy is used to maintain a stable cutting load and avoid over – cutting or under – cutting.

Accuracy Compensation and Error Control

The motion chain of multi – axis machine tools is complex, and geometric errors and thermal deformation errors are likely to occur. Precision detection is carried out using equipment such as laser interferometers and ball – bar gauges, and an error compensation model is established to correct the parameters of the CNC system. In addition, temperature sensors are used to monitor the thermal deformation of the machine tool in real – time, and combined with thermal error compensation algorithms to improve machining accuracy.

III. CNC Multi – axis Machining Process

Part Analysis and Process Planning

Analyze the structural characteristics, accuracy requirements, and material properties of the part to determine the machining process route. For example, for aero – engine blades, a step – by – step strategy of roughing, semi – finishing for surface forming, and finishing for contour smoothing needs to be planned. The tools, cutting parameters, and clamping methods used in each process are also clearly defined.

3D Modeling and Programming

Complete the 3D modeling of the part using CAD software and import it into CAM software for tool – path design. Set cutting parameters, safe height, approach and retract methods, etc. according to the process plan, generate the NC machining program, and verify the feasibility of the program through simulation to avoid collisions and interferences in actual machining.

Workpiece Clamping and Tool Setting

Select special fixtures (such as the double – tilting table fixture commonly used in five – axis machining centers) to fix the workpiece to ensure positioning accuracy. Use a tool – setting instrument or the trial – cutting method to accurately measure the tool length and radius compensation values, and establish the correspondence between the workpiece coordinate system and the machine – tool coordinate system.

Processing Process Monitoring

Start the machine tool to execute the machining program, and monitor parameters such as cutting force, spindle load, and tool wear in real – time. Capture abnormal signals through built – in sensors of the machine tool or external monitoring equipment (such as vibration sensors), and adjust machining parameters or replace tools in a timely manner to ensure processing stability.

Quality Inspection and Post – processing

After machining, use equipment such as coordinate measuring machines and blue – light scanners to detect the dimensional accuracy, geometric tolerance, and surface roughness of the part. Re – machine unqualified parts, and complete post – processing procedures such as deburring, cleaning, and rust – prevention.

IV. Processable Materials for CNC Multi – axis Machining

Metallic Materials

High – temperature Alloys: Such as nickel – based alloys and titanium alloys, which are widely used in aero – engine components. Multi – axis machining can achieve the precision forming of complex cooling channels and blade profiles.

High – strength Alloy Steels: Used for manufacturing automotive molds and medical device parts. Through multi – axis milling, deep – cavity thin – wall structures can be processed to reduce stress concentration.

Non – ferrous Metals: Light metals such as aluminum alloys and magnesium alloys. In the aerospace and 3C product fields, multi – axis machining can efficiently process thin – walled shells and complex – curved – surface housings.

Non – metallic Materials

Engineering Plastics: Such as Polyetheretherketone (PEEK) and Polycarbonate (PC), which are often used in medical implants and precision instrument housings. Multi – axis machining can ensure the high – precision forming of complex shapes.

Composite Materials: Carbon – Fiber – Reinforced Polymer (CFRP) and Glass – Fiber – Reinforced Polymer (GFRP). In aerospace and wind – turbine blade manufacturing, multi – axis machining can avoid delamination and fiber damage, improving material utilization.

V. Parts Processed by CNC Multi – axis Machining

Aerospace Category

Engine Blades: Five – axis simultaneous machining is used to achieve the one – time forming of twisted blade profiles, reducing splicing errors and improving aerodynamic performance.

Integral Blisks: The combination of multi – axis milling and electrical – discharge machining is adopted to directly process the integrated structure of blades and discs from the blank, reducing weight and improving reliability.

Mold – making Category

Injection Molds: Machining the complex cavities of automotive interior part molds, realizing the one – time forming of structures such as undercuts and side holes, and shortening the mold – making cycle.

Die – casting Molds: Multi – axis polishing is carried out on the mold surface to improve surface finish and reduce the demoulding resistance of die – cast parts.

Medical Equipment Category

Artificial Joints: According to the personalized needs of patients, titanium – alloy hip and knee joint prostheses are customized through multi – axis machining to ensure precise matching with human bones.

Medical Device Housings: Machining the precision housings of minimally invasive surgical instruments, ensuring dimensional accuracy and surface quality to meet the strict requirements of the medical industry.

VI. Application Fields of CNC Multi – axis Machining

Aerospace Industry

It is used for manufacturing aircraft fuselage structural parts, high – temperature engine components, aero – engine integral blisks, etc., and is a key technology to achieve lightweight and high – performance aerospace equipment. For example, the wing structural parts of the Airbus A380 are processed by five – axis machining, reducing the assembly workload by 30%.

Automotive Manufacturing Industry

It is widely used in automotive mold manufacturing, new – energy vehicle battery – pack housing, and precision transmission part machining. Multi – axis machining can achieve the rapid manufacturing of automotive body panel molds, shortening the R & D cycle of new vehicle models.

Energy Industry

It is applied to the machining of wind – turbine blade molds, gas – turbine blades, and nuclear – power equipment parts, improving the efficiency and reliability of energy equipment. For example, gas – turbine blades processed by five – axis machining can increase the power – generation efficiency by 5% – 8%.

High – end Equipment Manufacturing

It is used for processing key parts of five – axis machining centers, industrial robot joint parts, and precision medical device parts, promoting the localization and intelligent development of high – end equipment.

VII. Technical Description of CNC Multi – axis Machining

CNC multi – axis machining is one of the core technologies for the high – end and precision development of modern manufacturing. It integrates the achievements of multiple disciplines such as numerical control technology, computer – aided design and manufacturing, and sensor technology. Compared with traditional processing methods, multi – axis machining has significant advantages: first, it reduces the number of clamping times, avoids repeated positioning errors, and improves machining accuracy; second, it can machine complex curved surfaces, breaking through the geometric limitations of three – axis machining; third, by optimizing the tool attitude, it extends the tool life and reduces production costs.

With the development of intelligent manufacturing technology, CNC multi – axis machining is evolving towards high – speed, intelligent, and compound directions. High – speed multi – axis machining technology significantly improves processing efficiency by increasing the spindle speed and feed rate. Intelligent processing systems integrate real – time monitoring and adaptive control functions to achieve autonomous optimization of the machining process. Multi – axis compound machining machine tools (such as turning – milling compound and milling – grinding compound) integrate multiple processing technologies, further shortening the process flow. In the future, multi – axis machining technology will play a more important role in high – end manufacturing fields such as aerospace, new energy, and medicine, becoming a key driving force for the transformation and upgrading of the manufacturing industry.

The above interprets CNC multi – axis machining from multiple dimensions. If you want to know application cases in specific fields or discuss the technical details of a certain link in depth, feel free to talk to me at any time.