1. Introduction

In modern manufacturing, the selection of machining technology directly impacts product quality, production efficiency, and cost control. Computer Numerical Control (CNC) machining and traditional manual machining represent two core manufacturing approaches, embodying the characteristics of automated production and traditional craftsmanship, respectively. This article analyzes their technical principles, performance differences, and application scenarios to provide a scientific basis for manufacturing professionals to make informed decisions.

2. Technical Definitions and Working Principles

2.1 CNC Machining

CNC machining is a subtractive manufacturing process that uses computer control to automate material removal from a workpiece to produce custom-designed parts. The workflow involves:

- Design Modeling: Creating a 3D digital model using CAD software (e.g., SolidWorks);

- Programming: Translating the model into G-code instructions readable by CNC machines;

- Automated Machining: The machine executes precise cutting paths via servo motors, driven by pre-programmed instructions, to shape the workpiece.

Core Advantages: Achieves tolerances as tight as ±0.001mm, supports multi-axis (up to 5-axis) machining, and is ideal for mass-producing complex parts.

2.2 Traditional Machining

Traditional machining relies on manual operation of machines such as lathes, milling machines, and drill presses. Operators control tool movement via levers and dials, adjusting parameters like cutting speed and feed rate based on experience. The process includes:

- Workpiece Clamping: Securing the raw material in a vise or fixture;

- Manual Cutting: Operating the machine while observing and adjusting the process in real time;

- Measurement and Refinement: Checking dimensions with tools like calipers and making iterative adjustments.

Core Characteristics: High flexibility for prototype development, but precision is heavily dependent on operator skill.

3. Key Performance Comparison

| Dimension | CNC Machining | Traditional Machining |

|---|---|---|

| Precision & Repeatability | Tolerances of ±0.001mm–±0.01mm, high consistency | Tolerances of ±0.05mm–±0.1mm, operator-dependent |

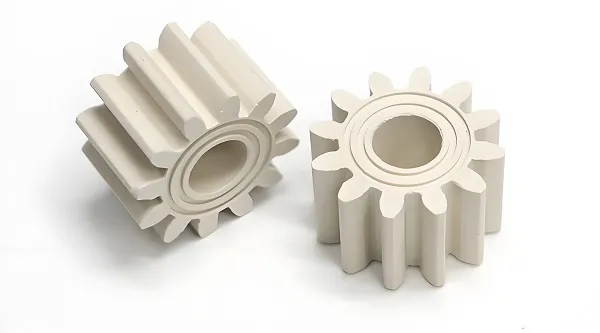

| Complex Geometry Handling | Supports multi-curved surfaces and intricate structures | Limited to simple profiles; complex shapes require multi-step processes |

| Material Compatibility | Processes hard/brittle materials (e.g., titanium, ceramics) | Primarily works with soft materials (e.g., aluminum, low-carbon steel) |

| Production Efficiency | High-speed automated batch production | Slower manual operation, suitable for small batches |

| Initial Cost | High (industrial machines: $10k–millions) | Low (basic lathes: thousands of dollars) |

| Skill Requirement | Requires programmers; lower operator | Demands highly skilled machinists with long training cycles |

4. In-Depth Analysis of Advantages and Limitations

4.1 Advantages and Limitations of CNC Machining

Advantages:

- High Precision: Eliminates human error, critical for industries like aerospace (e.g., engine impellers) and medical devices (e.g., implants).

- Complex Geometry Capability: 5-axis machines can produce parts in one setup that traditional methods require multiple steps for, reducing clamping errors.

- Scalability: 24/7 continuous operation lowers unit costs for large batches.

Limitations:

- High Upfront Investment: Costs for machines, software, and programming are prohibitive for small businesses.

- Limited Flexibility: Time-consuming reprogramming for design changes makes it inefficient for low-volume or custom projects.

4.2 Application Scenarios and Challenges of Traditional Machining

Advantages:

- Low-Cost Prototyping: Ideal for startups or artisanal projects requiring one-off custom parts.

- Real-Time Adjustability: Operators can make immediate modifications during machining, suitable for non-standard requirements.

- Simple Maintenance: No complex electronics, making it viable in remote or unstable power environments.

Challenges:

- Productivity Bottlenecks: Manual operations slow down mass production, limiting output capacity.

- Quality Variability: Inconsistencies between operators make it hard to meet international standards like ISO.

5. Application Scenario Selection Strategies

- Precision-Critical Scenarios:

- CNC machining is preferred for medical implants and aerospace components requiring strict tolerance control.

- Low-Volume & Customization Scenarios:

- Traditional machining offers cost advantages for automotive modifications or artistic sculptures.

- Special Material Scenarios:

- Hard materials (e.g., quenched steel above HRC50) require CNC’s advanced tools (e.g., carbide cutters) or EDM.

- Hybrid Models:

- Combine “CNC roughing + traditional finishing” for complex parts to balance efficiency and cost.

6. Manufacturing Solution Case Study

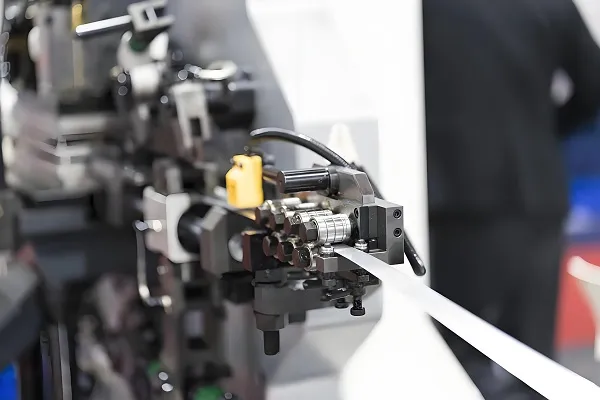

Platforms like Xiamen Goldcattle provide end-to-end CNC machining services via cloud-integrated multi-axis machines. Key benefits include:

- Lower Entry Barrier: Access high-precision machining without equipment investment.

- Technical Integration: Support for 3-axis to 5-axis machining across 50+ materials (e.g., aluminum, titanium, PEEK).

- Rapid Turnaround: Prototype delivery within 72 hours, accelerating new product iteration.

7. Conclusion

CNC machining and traditional machining are complementary rather than mutually exclusive. The former drives industrial-scale production, while the latter retains irreplaceable value in customization and low-threshold scenarios. Enterprises should choose based on project precision requirements, batch size, material properties, and budget. As Industry 4.0 advances, intelligent CNC technology continues to expand its applications, but traditional craftsmanship remains vital for flexibility and human-centric innovation.