In the intricate landscape of modern manufacturing, the term “CNC” frequently emerges as a cornerstone of technological advancement. But what does CNC stand for? CNC is an acronym that stands for Computer Numerical Control. At its core, CNC represents a revolutionary approach to controlling machine tools, leveraging computer systems to automate and precisely manage the movement and operation of machinery. This technology has transformed traditional manufacturing processes, offering unparalleled precision, efficiency, and flexibility.

The Basics of CNC

CNC systems operate by interpreting digital instructions, typically in the form of G – code or M – code, which are programming languages specifically designed for controlling machine tools. G – code, for example, is used to specify the toolpath, such as linear and circular interpolation movements. M – code controls auxiliary functions like spindle start/stop, coolant on/off, and tool changes. These codes contain detailed information about the toolpath, speed, feed rate, and other parameters required to perform a specific machining operation. For instance, in a CNC milling machine, the G – code will precisely define the coordinates of the points that the cutting tool needs to follow, the depth of the cut (which can be controlled to within micrometers in high – end machines), and the rotational speed of the spindle, often measured in revolutions per minute (RPM) and adjustable from a few hundred to tens of thousands of RPM depending on the material and operation.

The integration of computers into the control system of machine tools is what sets CNC apart from traditional manual or mechanical control methods. In manual machining, an operator directly controls the movement of the tool using levers, handles, and dials. This approach is highly dependent on the skill and experience of the operator and is prone to human error. A study has shown that manual machining error rates can be as high as 10 – 15% in complex operations. Mechanical control systems, on the other hand, use cams, gears, and other mechanical components to guide the tool, but they lack the flexibility and precision offered by CNC. Mechanical systems are limited in their ability to execute complex geometries and typically have a repeatability error in the range of ±0.1 – 0.5 mm.

CNC systems, however, can execute complex machining operations with a high degree of accuracy, repeatability, and consistency. High – end CNC machines can achieve positional accuracy of ±0.001 – 0.01 mm and repeatability of ±0.0005 – 0.005 mm. Once the program is loaded into the CNC controller, the machine can automatically perform the same operation multiple times without significant variations, ensuring the production of identical parts. This makes CNC technology ideal for mass production, where large quantities of parts need to be manufactured with tight tolerances. For example, in the automotive industry, engine components such as cylinder heads require tight tolerances (within ±0.05 mm) for proper fit and function, and CNC machining can consistently meet these requirements.

The Components of a CNC System

A typical CNC system consists of several key components, each playing a crucial role in its operation. The CNC controller, also known as the machine control unit (MCU), is the brain of the system. It receives the digital instructions from the computer, processes them, and sends control signals to the various components of the machine tool. Modern CNC controllers are often equipped with multi – core processors, which can handle complex machining algorithms in real – time. They also feature high – resolution displays and user – friendly interfaces for programming, monitoring, and controlling the machining process. Some advanced controllers support touch – screen operation and have built – in diagnostic tools to quickly identify and resolve issues.

The servo motors are another essential component of a CNC system. These motors are responsible for driving the axes of the machine tool, converting the electrical signals from the controller into precise mechanical movements. Servo motors are highly accurate and can provide smooth, continuous motion, enabling the machine to achieve the required precision in machining. They are often equipped with encoders, which provide feedback to the controller about the position and speed of the motor, allowing for closed – loop control and ensuring that the actual movement of the tool matches the programmed instructions. High – performance servo motors can achieve acceleration rates of up to 10 – 20 m/s² and positioning accuracies of ±0.001 mm.

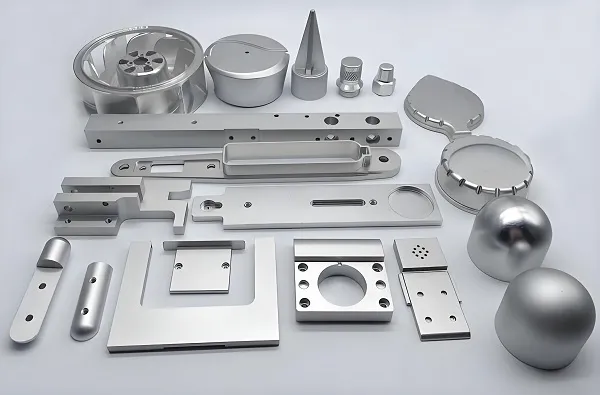

In addition to the controller and servo motors, a CNC system also includes the machine tool itself, which can be a milling machine, lathe, router, plasma cutter, or other types of equipment. The machine tool is designed to perform specific machining operations, such as cutting, drilling, turning, or shaping, and it is equipped with the necessary components, such as spindles, cutting tools, and workholding devices, to carry out these tasks. Spindles in CNC machines can have high – speed capabilities, with some milling spindles reaching speeds of 50,000 – 100,000 RPM for fine – machining operations. Cutting tools are selected based on the material being processed and the type of operation, and they can range from carbide – tipped end mills for metal cutting to diamond – coated tools for machining hard materials like ceramics. Workholding devices, such as vises, chucks, and fixtures, are used to securely hold the workpiece in place during machining, ensuring accurate and repeatable results.

The computer system, which runs the CNC software and generates the digital instructions, is also a vital part of the system. This can be a desktop computer, laptop, or a dedicated industrial computer, depending on the complexity and requirements of the machining operation. Industrial computers are often preferred in manufacturing environments due to their robustness, ability to withstand harsh conditions, and high – reliability components. They are typically equipped with specialized CNC software that integrates computer – aided design (CAD) and computer – aided manufacturing (CAM) functions. CAD software allows designers to create 3D models of parts, while CAM software generates the toolpaths and G – code based on these models, streamlining the programming process.

Applications of CNC Technology

The versatility of CNC technology has led to its widespread adoption across a diverse range of industries. In the aerospace industry, CNC machining is used to manufacture complex components for aircraft engines, wings, and fuselages. These parts often require high precision and tight tolerances to ensure the safety and performance of the aircraft. For example, turbine blades in aircraft engines are manufactured with tolerances as tight as ±0.01 – 0.02 mm. CNC machines can produce parts with intricate geometries and surface finishes that are difficult or impossible to achieve using traditional machining methods. The use of five – axis or even multi – axis CNC machines in aerospace manufacturing allows for the production of parts with complex curved surfaces in a single setup, reducing the need for multiple operations and improving overall part quality.

The automotive industry also relies heavily on CNC technology for the production of engine components, transmission parts, and body panels. CNC machining allows for the efficient production of high – quality parts in large quantities, reducing production costs and improving the overall quality of the vehicles. Engine blocks, which are critical components in automobiles, are machined with high precision using CNC milling and boring machines to ensure proper fit and function of the engine components. In the production of transmission gears, CNC machining can achieve the required tooth profiles and tolerances, resulting in smoother gear operation and reduced noise. Additionally, CNC – controlled robots are used in automotive assembly lines for tasks such as welding, painting, and material handling, further enhancing production efficiency.

In the medical field, CNC machines are used to manufacture medical implants, surgical instruments, and prosthetics. The precision and accuracy of CNC machining are crucial in these applications, as the parts need to fit precisely and meet strict medical standards. For example, dental implants are often made from titanium or other biocompatible materials and are machined with tolerances of ±0.05 – 0.1 mm to ensure proper osseointegration with the patient’s bone. In the production of orthopedic implants such as hip and knee replacements, CNC machining allows for the creation of custom – fit implants based on patient – specific anatomical data, improving the effectiveness of the implants and patient outcomes.

CNC technology is also widely used in the woodworking, plastics, and metalworking industries. In woodworking, CNC routers can create intricate designs and patterns on wood surfaces, enabling the production of custom furniture, cabinetry, and decorative items. These routers can achieve cutting accuracies of ±0.1 – 0.2 mm, allowing for detailed and precise woodworking. In the plastics industry, CNC machines are used for cutting, shaping, and drilling plastic materials. They can handle a variety of plastic materials, from soft polymers to hard engineering plastics, and are capable of producing parts with smooth surfaces and tight tolerances. In metalworking, CNC milling machines, lathes, and grinders are used to manufacture a wide range of metal parts, from simple brackets to complex aerospace components. CNC grinding machines can achieve surface finishes as low as Ra 0.05 – 0.1 µm, which is essential for applications where high – precision and smooth surfaces are required.

The Evolution of CNC Technology

The concept of numerical control dates back to the 1940s and 1950s, when the U.S. military began exploring ways to automate the machining of complex parts for military equipment. The first CNC machines were large, expensive, and used punched cards to store the digital instructions. These early machines were slow and had limited capabilities, with processing speeds measured in kilobytes per second and limited memory for storing programs.

Over the years, advancements in computer technology, electronics, and software have led to significant improvements in CNC systems. The development of microprocessors in the 1970s and 1980s made CNC controllers smaller, more powerful, and more affordable. Microprocessors with clock speeds in the range of 1 – 10 MHz replaced the bulky and slow – performing mainframe – based control systems, enabling faster processing of machining instructions. This led to the widespread adoption of CNC technology in industries beyond the military.

The introduction of graphical user interfaces (GUIs) and computer – aided design (CAD) and computer – aided manufacturing (CAM) software in the 1980s and 1990s further enhanced the usability and functionality of CNC systems. CAD/CAM software allows designers to create 3D models of parts and generate the corresponding G – code programs automatically, reducing the time and effort required for programming CNC machines. The early CAD/CAM software had basic 2D and 3D modeling capabilities, but as technology advanced, these software packages now offer highly sophisticated features such as parametric modeling, simulation of machining processes, and integration with enterprise resource planning (ERP) systems.

In recent years, the integration of CNC technology with the Internet of Things (IoT), artificial intelligence (AI), and machine learning has opened up new possibilities for the future of manufacturing. Smart CNC machines can now collect and analyze data from various sensors, enabling predictive maintenance, process optimization, and quality control. For example, sensors can monitor the temperature, vibration, and wear of cutting tools in real – time. AI and machine learning algorithms can then analyze this data to predict when a tool is likely to fail, allowing for proactive tool replacement and minimizing unplanned downtime. These algorithms can also optimize the machining process by adjusting parameters such as feed rate, spindle speed, and cutting depth based on real – time data, improving productivity and part quality.

Advantages and Challenges of CNC Technology

CNC technology offers numerous advantages over traditional machining methods. The high precision and accuracy of CNC machines ensure that parts are manufactured to exact specifications, reducing the need for manual inspection and rework. As mentioned earlier, high – end CNC machines can achieve positional accuracies of ±0.001 – 0.01 mm, which is far beyond what can be achieved manually. The repeatability of CNC machining also allows for the production of identical parts, which is essential for mass production and assembly operations. In a production run of thousands of parts, CNC machines can maintain consistency within tight tolerances, ensuring seamless assembly.

CNC machines can operate continuously for long periods, increasing productivity and reducing production lead times. They can run 24/7 with minimal human intervention, except for periodic tool changes and maintenance. Some factories that rely on CNC machining have reported up to 30 – 50% reduction in production lead times compared to traditional machining methods. They can also perform multiple machining operations in a single setup, eliminating the need for manual part handling and reducing the risk of errors. For example, a five – axis CNC milling machine can perform milling, drilling, and tapping operations on a single workpiece without the need to re – fixture the part, improving both efficiency and accuracy.

The flexibility of CNC technology enables the production of complex parts with a wide range of geometries, and it allows for quick and easy changes to the machining program, making it suitable for both batch production and custom manufacturing. With a simple change in the CAD/CAM model and the corresponding G – code, a CNC machine can switch from producing one type of part to another, reducing the time and cost associated with tooling changes in traditional manufacturing.

However, CNC technology also presents some challenges. The initial investment in CNC machines and software can be significant, making it a costly option for small and medium – sized enterprises. A high – end multi – axis CNC machining center can cost anywhere from $500,000 to several million dollars, and the associated software licenses and training can add tens of thousands of dollars more. The programming and operation of CNC machines require specialized skills and training, and the maintenance and repair of these complex systems can be time – consuming and expensive. CNC technicians need to be proficient in programming languages, machine operation, and troubleshooting, and training programs can take several months to a year to complete. Additionally, the reliance on computer systems and digital instructions means that CNC machines are vulnerable to cyberattacks, which can disrupt production and compromise the security of manufacturing operations. A study by a leading cybersecurity firm found that up to 30% of manufacturing facilities have experienced some form of cyberattack on their CNC systems in the past five years, with potential losses ranging from production downtime to theft of intellectual property.

In conclusion, CNC, or Computer Numerical Control, is a transformative technology that has revolutionized the manufacturing industry. From its humble beginnings as a military innovation to its current status as a cornerstone of modern manufacturing, CNC technology has continuously evolved to meet the changing needs of industries worldwide. With its ability to provide precision, efficiency, and flexibility, CNC technology will undoubtedly continue to play a vital role in the future of manufacturing, driving innovation and shaping the way we produce goods in the digital age. Whether it’s in aerospace, automotive, medical, or other industries, the impact of CNC technology on modern manufacturing is undeniable, and its potential for further development and advancement is limitless.