The most common CNC language is G-code.

Why is G-code considered the standard?

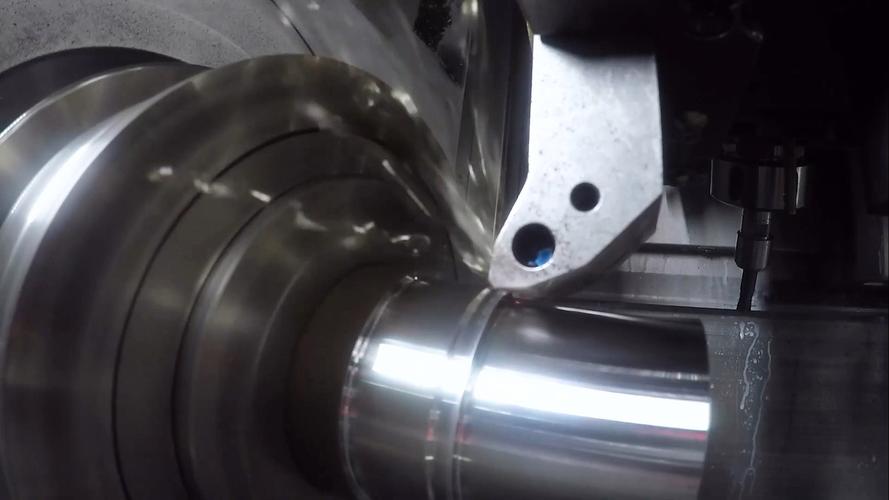

G-code, short for “Geometric Code,” is the universal programming language used to control CNC (Computer Numerical Control) machines. Its widespread adoption stems from its simplicity in defining toolpaths, movements, and machining operations—such as drilling, milling, turning, or cutting. Developed in the 1950s, G-code has evolved into a de facto standard across industries, with most CNC controllers (from brands like Fanuc, Siemens, and Haas) supporting it, either natively or with minimal adaptations.

What does G-code control?

G-code commands dictate precise actions of the CNC machine, including:

- Axis movements (e.g., G00 for rapid positioning, G01 for linear interpolation at a specified feed rate).

- Spindle operations (e.g., G97 for constant spindle speed, G81 for simple drilling cycles).

- Tool changes and work offsets to ensure accuracy.

While some manufacturers use proprietary extensions (e.g., Fanuc’s custom G-codes), the core commands remain consistent, making G-code interoperable across most machines.

Are there other CNC languages?

Yes, but they are less universal. For example:

- M-code (Miscellaneous Code) often works alongside G-code to control auxiliary functions like coolant on/off or spindle start/stop.

- ISO codes or vendor-specific languages (e.g., Siemens’ Sinumerik) may refine G-code logic for advanced applications but still rely on G-code fundamentals.

In summary, G-code remains the backbone of CNC programming due to its standardization, versatility, and broad compatibility.