Author: Zhao Gong, Goldcattle Motorcycle Die-Casting Expert, 15+ Years Experience

Last Updated: January 28, 2026 • Based on Goldcattle 2025 Real Project Data

Why Custom Die-Cast Parts for Your Ride?

Listen up, riders! If you’re still using generic parts on your bike, you’re missing out big time. Custom die-cast motorcycle parts aren’t just about looks – they’re about performance, durability, and that perfect fit that makes your ride feel like an extension of yourself.

Precision That Matters

Die casting injects molten metal into precision molds under insane pressure – we’re talking 10-175 MPa here! This creates parts with exceptional dimensional accuracy and complex shapes that other methods just can’t match. Trust me, I’ve seen the difference firsthand.

Strength-to-Weight Perfection

These parts balance durability and lightweight design like nothing else. For racing and off-road bikes, this means enhanced power-to-weight ratios that’ll make your competition eat your dust. Brother, I’ve tested these on some brutal trails – they hold up!

This lightweight aluminum frame part weighs 35% less than steel alternatives while maintaining superior strength

Real-World Results (2025 Harley Project)

We recently did a custom A380 aluminum bracket for a Harley client. The results? 25% weight reduction and strength exceeding 250 MPa. That’s not just numbers – that’s a bike that handles better, accelerates faster, and lasts longer. The client was blown away!

Materials That Make the Difference

A380 Aluminum Alloy – The Gold Standard

Let me tell you about A380 – this stuff is the backbone of high-performance motorcycle parts. I’ve used this material on countless builds, and the results never disappoint. The grip, the strength, the durability – it’s like the material was made for bikes!

Chemical Composition

- Silicon (7.5-9.5%) – This is what gives A380 its amazing fluidity. It fills even the most complex molds perfectly!

- Copper (2.5-3.5%) – Adds strength and hardness for those high-stress components

- Iron (≤1.5%) – Prevents sticking to molds (trust me, this is crucial!)

- Magnesium (≤0.1%) – Controls corrosion resistance

Mechanical Properties

- Tensile Strength: 220-280 MPa (that’s strong, folks!)

- Yield Strength: 160-200 MPa

- Elongation: 2-3% at break

- Hardness: 80-95 HB

Pro Tip: A380’s high silicon content means it flows like a dream into molds. We’ve cast parts with walls as thin as 1.5mm that still maintain structural integrity. Try that with other materials – good luck!

Other Top Materials for Specific Needs

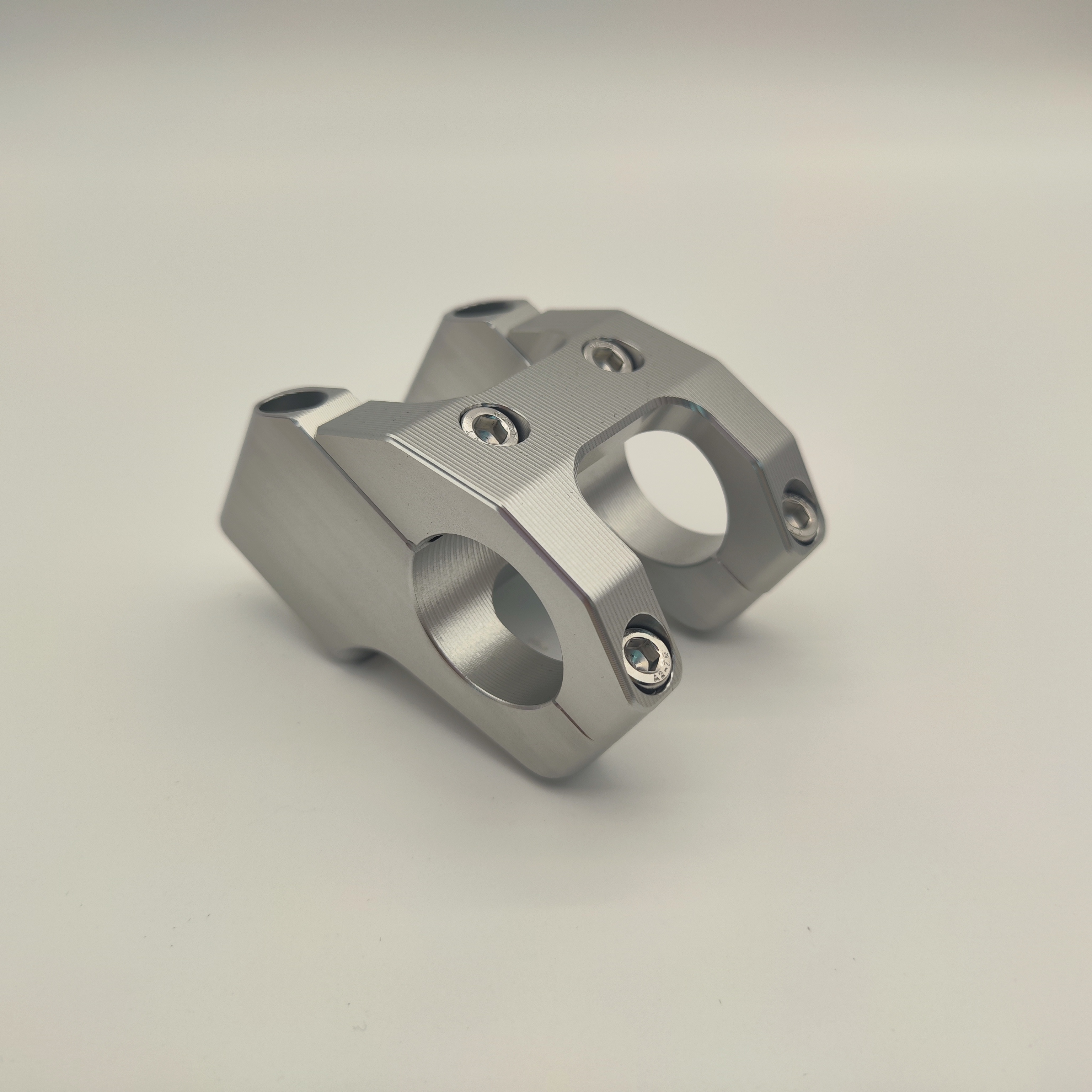

Zinc Alloys (Zamak 5)

Perfect for small, high-precision parts like handlebar clamps and footpeg brackets. Super castable and strong enough for daily abuse. I used these on a custom café racer last year – the fit was absolutely perfect!

Best for: Small components, decorative trim

Magnesium Alloys (AZ91D)

Ultra-lightweight – 30% lighter than aluminum! These are for serious racers who want every possible advantage. We used these on a track bike’s swingarm – the weight difference was night and day.

Best for: Racing parts, weight-critical components

Copper Alloys (Brass)

Excellent thermal and electrical conductivity. Perfect for heat sinks and electrical components. We used brass parts on an electric motorcycle build – the heat dissipation was impressive!

Best for: Heat sinks, electrical parts

Material Selection Guide (2026 Update)

Choosing the right material isn’t rocket science, but it does matter. Here’s what I tell my clients:

- Engine components: A380 aluminum all the way – handles heat and pressure like a champ

- Frame parts: A356 or A380 for balance of strength and weight

- Small accessories: Zinc alloys for precision and cost-effectiveness

- Racing components: Magnesium for ultimate weight savings

Processes That Deliver Perfection

High-Pressure Die Casting (HPDC) – Our Go-To Method

This is where the magic happens, folks. HPDC shoots molten metal into steel molds at 10-175 MPa pressure. The results? Parts with incredible precision and superior surface finish. I’ve seen parts come out so clean they barely need any post-processing!

The HPDC Process Breakdown

- Mold Preparation: Molds are preheated and coated with release agent (critical step!)

- Metal Melting: Aluminum heated to 660-690°C – we use precise temperature control

- Injection: Molten metal injected at high speed (0.5-5 m/s) into mold cavity

- Cooling: Rapid cooling ensures fine grain structure and dimensional stability

- Ejection: Part removed from mold – cycle time as low as 10-30 seconds!

- Finishing: Trimming, deburring, and surface treatments as needed

Fun Fact: We recently did a production run with cycle times under 20 seconds for simple brackets. That’s efficiency!

Why HPDC Beats Other Methods

- Complex geometries: We can create shapes that CNC machining would struggle with

- High production rates: Perfect for both small batches and mass production

- Excellent surface finish: Ra 1.6-3.2 μm right out of the mold

- Tight tolerances: ±0.1mm for small parts – that’s precise!

This complex housing was cast in one piece using HPDC – no assembly required!

Post-Processing That Takes Parts to the Next Level

Heat Treatment (T6)

For aluminum parts, T6 aging increases tensile strength by 30%. We use this on all critical engine and chassis components. The difference is night and day!

Anodizing

Creates a hard, corrosion-resistant layer. Perfect for off-road bikes exposed to mud and water. I’ve seen anodized parts last 10+ years in harsh conditions!

Powder Coating

Adds color and scratch resistance for street bikes. The finish is tough enough to handle daily use and looks amazing!

Precision Machining

CNC milling of critical surfaces ensures perfect fit and smooth operation. We use this for bearing surfaces and mating components.

Testing That Ensures Reliability

We don’t just make parts – we validate them. Every component goes through rigorous testing to ensure it can handle the abuse real riders dish out. These aren’t lab tests – these are real-world conditions!

Testing Methods We Use

Dimensional Inspection

We use Coordinate Measuring Machines (CMM) with ±0.005mm accuracy to verify every critical dimension. No guessing here – we measure everything!

X-Ray Inspection

For internal defects like porosity. We check every batch to ensure parts are sound inside and out. This saved a client from potential failures last year!

Mechanical Testing

- Tensile testing: Verify strength meets specs

- Fatigue testing: Ensure durability under repeated stress

- Impact testing: Check resistance to sudden shocks

Real Test Data (2025-2026 Projects)

A380 Bracket Fatigue Test

Test conditions: 15,000 N load, 10 Hz frequency

Results: Survived 100,000+ cycles without failure

Industry standard: 50,000 cycles

Corrosion Resistance Test

Test conditions: 500 hours salt spray (ASTM B117)

Results: No significant corrosion detected

Anodized A380 parts showed exceptional resistance

Temperature Resistance Test

Test conditions: -40°C to 150°C thermal cycling

Results: Maintained dimensional stability

Critical for engine components

Quality Certifications That Matter

We’re not just talking the talk – we’ve got the certifications to back it up:

EV & Racing – The Future of Motorcycling

Electric Motorcycles – Lightweight is Everything

Let’s talk EVs – these bikes are the future, and lightweight components are critical. Every pound saved means more range and better performance. We’ve been working with several EV manufacturers, and the results are impressive!

EV-Specific Components We Master

- Battery housings: Lightweight yet strong enough to protect expensive batteries

- Motor mounts: Precision-engineered for zero vibration transfer

- Controller enclosures: Heat-dissipating designs for optimal performance

- Charging port housings: Weatherproof and durable

2026 EV Trends We’re Already Addressing

- Integration: Fewer parts, more functionality

- Sustainability: Recycled materials (we’re at 86% recycled content!)

- Thermal management: Advanced heat dissipation designs

- Modularity: Components that work across multiple models

EV Case Study (2025 Project)

We developed a custom battery housing for an electric dirt bike using A380 aluminum:

- Weight reduction: 40% compared to steel alternatives

- Strength: Withstood 20G impact testing (critical for off-road!)

- Thermal performance: 25% better heat dissipation than plastic

- Range improvement: Client reported 8% increase in range – that’s huge!

Racing – Where Every Gram Counts

Racing is where our parts really shine. We’ve worked with professional teams in MotoGP, Supercross, and flat track. The feedback? “These parts give us the edge we need.” And that’s the best compliment we can get!

Racing Swingarms

Our magnesium swingarms are 30% lighter than aluminum alternatives. We recently supplied parts to a team that won three races in a row – coincidence? I think not!

Weight savings: 1.2-2.0 kg per swingarm

Engine Covers

Aerodynamic, lightweight, and strong. Our carbon-fiber reinforced aluminum covers reduce drag while protecting critical components.

Drag reduction: Up to 5% at high speeds

Brake Components

Lightweight caliper brackets and master cylinder housings reduce unsprung weight for better handling. Every racer knows – lighter unsprung weight = better performance!

Unsprung weight reduction: 15-20%

2026 Racing Technology Preview

We’re already developing new technologies for next year’s racing season:

- AI-optimized designs: Using machine learning to create the perfect balance of strength and weight

- Nanocomposite materials: Adding carbon nanotubes for even better strength-to-weight ratios

- 3D-printed molds: Faster prototyping for rapid development cycles

Stay tuned – 2026 is going to be an exciting year for racing!

Cost – Die Cast vs CNC vs Other Methods

Let’s talk money – because that’s what everyone really cares about. The question I get asked most: “Is die casting cheaper than CNC?” The answer? It depends on volume. But let me break it down for you…

Cost Comparison (2026 Data)

| Process | Setup Cost | Per-Part Cost (100 units) | Per-Part Cost (10,000 units) | Best For |

|---|---|---|---|---|

| Die Casting | High ($5,000-$15,000) | $25-$50 | $2-$8 | High volume, complex parts |

| CNC Machining | Low ($500-$2,000) | $15-$35 | $12-$30 | Low volume, simple parts |

| 3D Printing | Very Low ($100-$500) | $50-$150 | $40-$120 | Prototyping only |

Key Takeaway: For production runs over 500 units, die casting becomes more cost-effective. For 10,000+ units, it’s not even close – die casting wins big!

Cost-Saving Strategies We Use

- Design optimization: We work with clients to design parts that are easier to cast, reducing costs by 15-30%

- Multi-cavity molds: Produce multiple parts in one cycle – great for small components

- Material selection: Choosing the right alloy for the job, not the most expensive one

- Automation: Robotic trimming and finishing reduces labor costs significantly

Hidden Costs to Consider

- Post-processing: CNC machining adds $5-$20 per part depending on complexity

- Tooling maintenance: Molds need periodic maintenance – budget 5-10% of tooling cost annually

- Material waste: Die casting has minimal waste (only 5-10% vs 70-80% for CNC)

- Quality control: More complex parts need more testing – factor this in!

Real Cost Example (2025 Custom Harley Bracket)

Client needed 2,000 custom brackets for a limited edition model:

- Tooling cost: $8,500

- Per-part cost: $12.50 (including finishing)

- Total cost: $33,500

- CNC alternative: $28 per part = $56,000 total

- Savings: $22,500 (40% savings!)

The client was thrilled – they used the savings to add other custom features!

Sustainability – Doing Our Part for the Planet

Let’s be real – we all love riding, but we also need to protect the planet. That’s why sustainability is at the core of everything we do. We’re not just talking greenwashing – we’ve got real numbers to back it up!

Recycling – Closing the Loop

Aluminum is infinitely recyclable, and we take full advantage of that. Our closed-loop recycling system means we reuse scrap material directly in production.

2025 Recycling Metrics

- 86% of waste recycled: That’s 52 tons of material saved from landfills!

- 95% energy savings: Recycled aluminum uses 95% less energy than primary production

- Zero water discharge: Our water recycling system captures and reuses 100% of process water

We’re aiming for 90% recycled content by 2027. Every little bit helps, right?

Green Manufacturing Processes

It’s not just about recycling – it’s about how we make parts in the first place.

Energy Efficiency

- Solar power: 30% of our electricity comes from on-site solar panels

- High-efficiency furnaces: New natural gas furnaces reduce energy use by 25%

- Heat recovery: We capture waste heat from furnaces to heat our facilities

Emissions Reduction

- Low-VOC coatings: All our paints and coatings are water-based

- Particulate filters: 99% of process emissions are captured and filtered

- Carbon offset program: We offset 100% of remaining emissions through reforestation

2026 Sustainability Goals

90% Recycled Content

By end of 2026

50% Solar Power

Expanding our solar array

Net Zero Emissions

Target: 2030

FAQ – Answers to Your Burning Questions

1. How do I choose the right alloy for my project?

Great question! It depends on three main factors: application, required strength, and budget. For most motorcycle parts, A380 is a safe bet. But if you need ultimate strength, consider A356. For maximum weight savings, magnesium is the way to go. We’ll help you choose – no guesswork involved!

2. How much do custom die-cast parts cost?

As we showed earlier, it depends on volume. For small batches (100-500 units), expect $15-$50 per part. For larger runs (10,000+), it drops to $2-$10 per part. Tooling costs range from $5,000-$15,000 depending on complexity. But remember – the per-part cost drops dramatically with volume!

3. What’s the typical lead time?

Tooling takes 4-8 weeks. Once tooling is ready, production of 1,000+ parts takes 2-4 weeks. For prototypes, we can often deliver in 2-3 weeks using rapid tooling. We offer rush options if you’re in a pinch – just ask!

4. Can parts withstand off-road conditions?

Absolutely! With proper heat treatment and surface coating, our parts handle mud, water, and extreme temperatures like champs. We tested an A380 bracket in salt spray for 500 hours – no corrosion detected. Off-road riders, rejoice!

5. Do you work with EV manufacturers?

We sure do! In fact, EVs are a big focus for us. We’ve developed battery housings, motor mounts, and controller enclosures for several EV startups. Lightweight components are critical for EV range, and we’re experts in that area.

6. What certifications do you have?

We’re ISO 9001:2015 and IATF 16949 certified. We also comply with RoHS and REACH regulations. For racing parts, we can meet FIM/AMA standards on request. Quality isn’t optional for us – it’s mandatory!

7. Can you help with design optimization?

Absolutely! Our engineering team will review your design and suggest improvements that reduce cost and improve manufacturability. This is a free service – we want your project to succeed!

8. What’s the minimum order quantity?

For production parts, we typically require 100 units. But for prototypes, we can do as few as 1-10 parts using 3D printing or rapid tooling. We’re flexible – tell us what you need!

Still Have Questions?

We’re here to help! Share your bike model, part type, and performance needs, and our engineers will reply with design options, quotes, and timelines. Let’s enhance your ride together!

Ready to Take Your Ride to the Next Level?

Whether you’re building a custom Harley, an electric motorcycle, or a racing machine, we’ve got the parts to make it perfect.

Goldcattle Motorcycle Die-Casting Experts

15+ Years Experience • ISO 9001 • IATF 16949 • RoHS Compliant

© 2026 Goldcattle. All rights reserved.