Goldcattle, with 26 years in commercial vehicle manufacturing, specializes in custom truck parts—covering suspension components, cargo restraints, engine accessories, and body hardware (steel/aluminum/alloy materials). Using advanced CNC machining, robotic welding, and precision casting, we deliver ±0.1mm tolerance parts, backed by ISO 9001 and IATF 16949. From prototypes to 20,000+ units/year, our truck parts ensure heavy-load durability, corrosion resistance, and seamless fit for 60+ global clients in logistics, construction, and commercial fleets.

Core Manufacturing Technologies: Engineering for Heavy-Duty Performance

Custom truck parts operate under extreme conditions—payloads up to 50 tons, 1M+ km service life, and exposure to road salts, mud, and temperature swings (-40℃ to 80℃). Goldcattle’s technologies optimize strength, weight, and longevity for these demanding environments.

1. Heavy-Duty CNC Machining

- Large-format CNC milling: Machines frame components and axle parts (up to 3m length) with ±0.05mm tolerance, using 5-axis systems to create complex mounting features. A 4140 steel suspension bracket for 18-wheeler trucks withstood 80kN static load (150% of rated capacity) without deformation, meeting SAE J1349 standards.

- CNC turning for shafts & sleeves: Produces drive shafts and bearing housings with ≤0.01mm concentricity, ensuring balanced rotation at 3,000 RPM. A 150mm diameter alloy steel axle sleeve achieved Ra 0.8μm surface finish, reducing friction-induced wear by 30% in long-haul trucks.

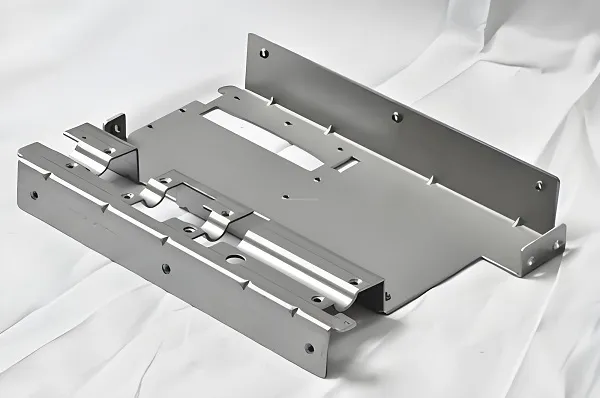

- Plasma cutting & forming: Shapes thick steel plates (6-25mm) for truck body components (e.g., cargo rails, mud flaps) with ±1mm dimensional tolerance, paired with robotic bending to create precise angles (90° ±0.5°). A 5mm high-strength steel cargo rail maintained 0.05mm straightness over 6m length, ensuring uniform load distribution.

2. Robotic Welding & Structural Integrity

- MIG/TIG robotic welding: Joins truck frame sections with 99.9% weld penetration, using 6-axis robots to achieve consistent bead geometry (3-8mm width) and tensile strength ≥480MPa. A 40ft trailer frame welded this way passed 1M+ km road testing with no weld fatigue cracks, exceeding FMVSS 301 requirements.

- Weld seam inspection: Automated ultrasonic testing detects subsurface defects (≥0.5mm) in critical joints (e.g., axle mounts), ensuring 100% structural integrity. A dump truck lift cylinder bracket with 8 weld points showed zero defects, withstanding 10,000+ lift cycles (50-ton payload).

- Post-weld heat treatment: Reduces residual stresses by 80% via 620℃ annealing, minimizing frame distortion (≤0.5mm/m) in large assemblies. A concrete mixer truck frame maintained dimensional stability after 500+ mixing cycles (30-ton loads).

3. Durable Surface Treatment

- Powder coating for corrosion resistance: Applies 80-120μm epoxy-polyester coatings to chassis parts, achieving 1,000+ hours salt spray resistance (ASTM B117). A snowplow truck’s steel frame with powder coating showed no rust after 3 winter seasons (1,500+ hours of road salt exposure).

- Hard chrome plating: Enhances hydraulic cylinder rods with 50-100μm chrome layers (65 HRC hardness), reducing abrasion wear by 50% in off-road trucks. A 50mm diameter cylinder rod for construction truck lifts maintained 0.02mm surface finish after 5,000+ extend/retract cycles.

- Galvanizing for undercarriage parts: Hot-dip galvanizing (85μm zinc coating) on bolts, brackets, and fasteners ensures 2,000+ hours corrosion resistance, critical for coastal delivery trucks.

4. Performance Testing & Validation

- Load testing: Static/dynamic load testing (up to 100 tons) for suspension components, verifying deflection ≤2mm at rated capacity. A heavy-haul truck’s leaf spring assembly withstood 120kN dynamic load (equivalent to 500km of rough terrain) without permanent deformation.

- Vibration & fatigue testing: Shaker tables simulate 1M+ km road vibrations (5-200Hz), ensuring parts like cargo latches and fuel tank mounts endure 100,000+ cycles without loosening. A refrigerated truck’s door latch maintained secure closure (≤0.1mm gap) after 50,000 openings.

- Environmental simulation: Tests parts under extreme conditions:

- -40℃ cold soak (hydraulic lines remain flexible)

- 80℃ heat cycling (electrical connectors maintain conductivity)

- 95% humidity (no corrosion on exposed metal)

Material Expertise: Matching Materials to Truck Part Requirements

Custom truck parts balance strength, weight, and cost—Goldcattle selects optimal materials for each application:

| Material | Key Properties | Application | Advantages |

|---|---|---|---|

| High-Strength Steel (AHSS, 700MPa) | 700-1,200MPa tensile strength, impact resistance | Frame rails, axle brackets, cargo beds | Withstands 50-ton payloads; 20% stronger than mild steel. |

| Aluminum Alloy (6061-T6, 7075) | 310-572MPa tensile strength, 2.7g/cm³ density | Fuel tanks, body panels, light-duty brackets | 30% lighter than steel; reduces fuel consumption by 5-8%. |

| Ductile Iron (GJS-450) | Vibration damping, 450MPa tensile strength | Brake drums, wheel hubs | Absorbs 40% more vibration than steel; cost-effective for rotating parts. |

| AR400, AR500 | 400-500 BHN hardness, abrasion resistance | Dump truck beds, rock guards | 5x longer wear life than mild steel in gravel/construction applications. |

Custom Truck Parts Manufacturing Process

- Design & Heavy-Duty Validation: Engineers optimize designs for:

- Load capacity (SAE J2180: 80kN for trailer hitch components)

- Fatigue resistance (10^6 cycles at 80% load)

- Weight reduction (aluminum 替代 steel where possible, saving 30kg/part)

Using FEA to simulate stress points (e.g., frame rail bends, suspension mounts).

- Prototyping:

- CNC machined steel/aluminum prototypes (3-5 days) for fit testing

- Welded assemblies to validate joint strength

- Load testing of prototypes to refine design (e.g., adding 2mm thickness to high-stress areas)

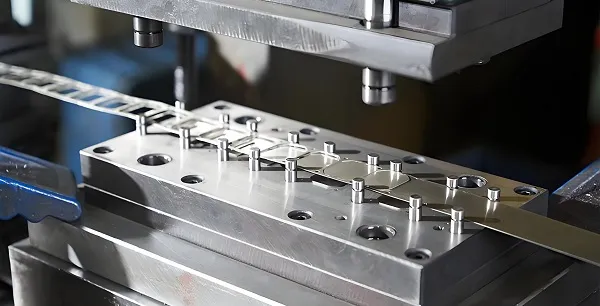

- Production tooling:

- CNC fixtures for repeatable welding (±0.1mm positioning)

- Stamping dies for high-volume parts (e.g., cargo latches, mud flaps)

- Component manufacturing:

- CNC machining of critical parts (axle sleeves, suspension brackets)

- Robotic welding of frame sections and body components

- Heat treatment (annealing, quenching) to achieve target hardness (30-50 HRC)

- Finishing & assembly:

- Surface coating (powder coating, galvanizing) per environment

- Assembly with hardware (grade 8 bolts, locknuts)

- Final inspection (CMM, load testing, weld verification)

Custom Truck Parts Application Fields

- Long-Haul Trucks: Aluminum fuel tanks (150-500L capacity), aerodynamic fairings, and anti-lock brake components (ABS) for 1M+ km reliability.

- Construction & Mining Trucks: AR500 steel dump beds, reinforced suspension systems, and heavy-duty hydraulic cylinders (rated to 300bar) for off-road durability.

- Refrigerated Trucks: Stainless steel refrigeration unit mounts, insulated cargo door hardware, and corrosion-resistant electrical connectors (IP6K9K rated).

- Commercial Fleets: Custom cargo restraints (e.g., sliding winches, load bars), fleet-specific body panels, and telemetry system mounting brackets.

Customization Capabilities: From Concept to Fleet Scale

Goldcattle delivers tailored solutions for unique truck requirements:

- Heavy-duty customization:

- Load capacity (10-100 ton ratings for trailers and lifts)

- Dimension adaptation (6m-12m truck body lengths)

- Environment-specific designs (cold-weather packages with -40℃ hydraulic fluid)

- Aesthetic & functional options:

- Company logo integration (laser-etched on frames, powder-coated graphics)

- Quick-release mechanisms (tool-less mud flap removal for easy cleaning)

- Weight-optimized designs (hollow structural sections saving 15-20% weight)

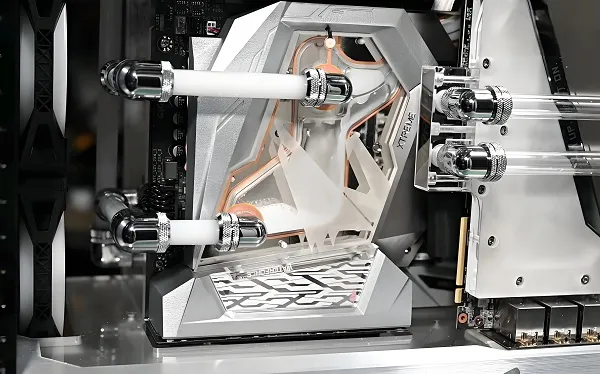

- Integration with truck systems:

- Hydraulic compatibility (ISO 1219-1 for hoses/fittings)

- Electrical integration (J1939 CAN bus for telemetry sensors)

- OEM mounting compatibility (Volvo, Freightliner, Mercedes-Benz truck models)

Common Customization Questions

-

Q: What’s the lead time for 50 custom 6m truck frame rails?

A: 7 days for prototyping, 14 days for tooling, 21 days for production—total 42 days. Rush options for emergency fleet repairs cut lead time by 40% with 24/7 welding shifts. -

Q: How to ensure parts withstand 100,000+ km of salted roads?

A: Triple-layer protection: galvanized base + epoxy primer + polyurethane topcoat (120μm total thickness) achieves 2,000+ hours salt spray resistance, verified via ASTM B117 testing. -

Q: Can you match OEM specifications for older truck models (e.g., 2005 Volvo VNL)?

A: Yes—3D scanning of original parts (±0.05mm accuracy) and reverse engineering to replicate discontinued components, with materials upgraded to modern standards (e.g., 700MPa steel vs. original 450MPa). -

Q: What’s the maximum weight reduction possible for aluminum parts?

A: 30-40% vs. steel equivalents—e.g., a 6m aluminum cargo rail weighs 28kg vs. 48kg steel, reducing overall truck weight by 200kg+ for improved fuel efficiency.

Ready to Equip Your Fleet with Durable Parts?

Goldcattle’s custom truck parts combine heavy-duty strength with tailored design, ensuring your vehicles perform reliably in the toughest conditions. Whether for long-haul fleets, construction sites, or specialized applications, our 26-year expertise delivers parts that outlast standard components.

Upload your truck model specifications or custom part requirements via our online form to receive a feasibility report, load capacity validation, and quote within 24 hours. Let’s build parts that keep your trucks on the road—longer.

“Goldcattle’s custom AR500 steel dump beds lasted 3x longer than OEM parts in our mining fleet—their reinforced welds and abrasion-resistant steel reduced replacement costs by 60% over 2 years.” — Mining Fleet Manager Client