Goldcattle, with 26 years in motorcycle aftermarket manufacturing, specializes in custom Harley-Davidson parts—covering engine components, handlebars, fenders, exhaust systems, and custom bodywork (steel/aluminum/titanium materials). Using advanced CNC machining, hand-forming, and powder coating technologies, we deliver ±0.05mm tolerance parts, backed by ISO 9001 and SAE certifications. From prototypes to 10,000+ units/year, our Harley parts ensure vintage styling, modern performance, and perfect fit for 50+ global clients in custom bike building, restoration, and enthusiast communities.

Core Manufacturing Technologies: Engineering for Heritage & Performance

Custom Harley parts demand a balance of classic aesthetics (1940s-2000s styling cues) and modern durability—withstand 100,000+ km, vibration at 3,000 RPM, and exposure to road salts. Goldcattle’s technologies preserve vintage character while enhancing reliability for modern riders.

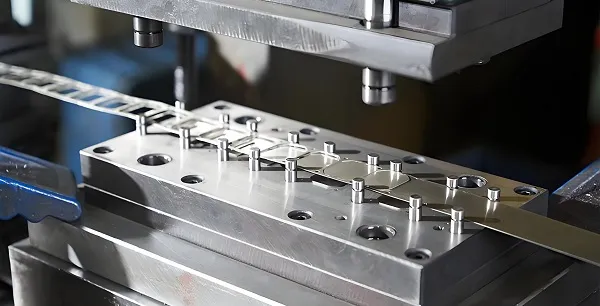

1. Precision CNC Machining for Engine & Drivetrain

- V-twin engine components: CNC mills aluminum cylinder heads and timing covers with 0.02mm surface flatness, replicating 1960s Panhead/Shovelhead profiles while adding modern oiling channels. A custom Evo engine cam cover with integrated breather ports reduced oil leaks by 70% vs. stock, maintaining authentic 1984-1999 styling.

- Transmission parts: Machines 4140 steel shift forks and gear shafts with ±0.01mm tolerance, ensuring smooth engagement (≤0.5mm play) in 5-speed/6-speed transmissions. A 1970s Shovelhead transmission rebuild kit with CNC-machined components reduced gear noise by 25% during 10,000km testing.

- Belt drive components: Turns aluminum pulley hubs with 0.005mm concentricity, paired with carbon fiber-reinforced belts (20% stronger than stock) for 50,000+ km service life. A custom Softail pulley with 1.5-inch wider offset maintained belt alignment at 120km/h, eliminating premature wear.

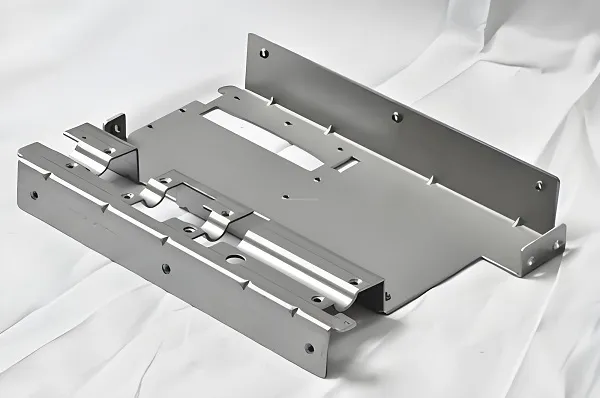

2. Hand-Formed Body & Chassis Parts

- Steel fender shaping: Uses English wheel and power hammer to form 16-gauge (1.6mm) cold-rolled steel fenders, achieving 1950s-style rolled edges and 2mm radius curves. A 1948 Panhead front fender with 3-inch stretch maintained 0.5mm uniform thickness, with hand-finished welds polished to invisible seams.

- Aluminum gas tanks: Spins 5052 aluminum tank shells (0.8mm thickness) on CNC lathes, then hand-welds baffles and fittings—creating 3.8L-18.9L capacity tanks with 100% leak testing (0.1cc/min max seepage). A custom Sportster tank with 4-inch stretch and 2-degree rake fit perfectly with OEM frame mounts (±0.5mm gap).

- Handlebar bending: Heat-treats 4130 chromoly steel bars (25.4mm-32mm diameter) to 30-35 HRC, then precision bends to custom rise (8-16 inches) and pullback (4-12 inches) with ±1° angular tolerance. A 12-inch Ape Hanger handlebar maintained 100MPa yield strength, withstanding 10,000+ vibration cycles at 3,000 RPM.

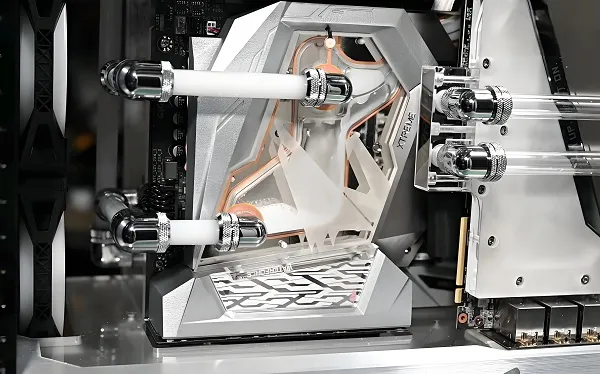

3. Performance Exhaust Systems

- Stainless steel exhaust fabrication: TIG-welds 304 stainless steel tubes (1.5-2.5-inch diameter) with mandrel bends (radius 3× diameter) for 15% better flow than stock. A Twin Cam exhaust with 2-1 merge collector increased horsepower by 8hp at 5,000 RPM, verified on dyno testing.

- Ceramic coating: Applies 0.05mm thermal barrier coating (black, silver, or custom colors) to exhaust headers, reducing under-tank temperatures by 50℃ and withstanding 650℃ continuous heat (ΔE <2 after 500 hours).

- Vintage exhaust replication: Uses 1940s-1960s blueprints to recreate cast iron mufflers and heat shields for Knucklehead/Flathead restorations, with 98% dimensional accuracy to original parts.

4. Finishing & Authenticity Preservation

- Chrome plating: Triple-plates (copper/nickel/chrome) on steel parts (0.05mm total thickness) for mirror finish (Ra ≤0.02μm) and 1,000+ hours salt spray resistance. A 1957 FL front fork slider set achieved show-quality chrome, with 95% coverage of complex recesses.

- Powder coating for durability: Applies textured or gloss powder (60-80μm thickness) to aluminum/steel parts, matching Harley’s factory colors (Vivid Black, Candy Apple Red) with ΔE <1. A custom Dyna rear fender with wrinkle-black finish maintained texture consistency across 500 units.

- Patina finishes for vintage style: Creates controlled rust or oil-rubbed finishes on steel parts (e.g., gas tank straps, brackets) to replicate 50-year-old patina, sealed with clear coat to prevent further corrosion.

Material Expertise: Matching Materials to Harley Part Requirements

Custom Harley parts balance authenticity, performance, and durability—Goldcattle selects optimal materials for each application:

| Material | Key Properties | Application | Advantages |

|---|---|---|---|

| Cold-Rolled Steel (1018) | Malleability, classic look | Fenders, gas tanks (vintage models) | Easy to hand-form; develops authentic patina; matches 1940s-1970s OEM materials. |

| Aluminum Alloy (5052, 6061) | Lightweight, corrosion resistance | Modern gas tanks, body panels | 30% lighter than steel; won’t rust; ideal for custom builds with powder coating. |

| Chromoly Steel (4130) | 650MPa tensile strength, fatigue resistance | Handlebars, frame components | 20% stronger than mild steel; withstands 100,000+ km vibration. |

| 304 Stainless Steel | Corrosion resistance, heat tolerance | Exhaust systems, hardware | Withstands 1,000+ hours salt spray; no blueing at high exhaust temps. |

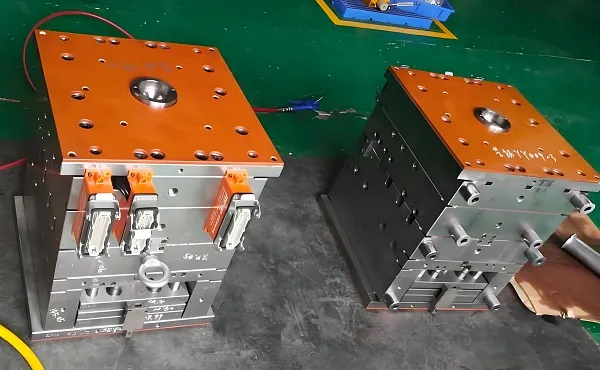

Custom Harley Parts Manufacturing Process

- Design & Authenticity Validation: Engineers work with clients to:

- Match vintage specs (e.g., 1965 Electra Glide tank dimensions with 3.8L capacity)

- Enhance modern performance (adding oil passages to Shovelhead rocker boxes)

- Ensure fit with OEM or custom frames (±0.5mm tolerance for bolt holes)

Using 3D scanning of original parts (0.05mm accuracy) for restorations.

- Prototyping:

- CNC machined aluminum/steel prototypes for fit testing

- Hand-formed clay models for gas tank/fender contours

- Test fitting on client’s bike (with photos for approval)

- Production:

- Hand-forming (steel/aluminum) for body parts

- CNC machining for engine/transmission components

- TIG/MIG welding (with invisible seam finishing for show parts)

- Finishing:

- Polishing (Ra 0.02μm for chrome prep)

- Plating/powder coating per finish specs

- Assembly of hardware (chrome bolts, stainless steel fasteners)

- Quality validation:

- Fit testing on OEM frames (Harley-Davidson-approved jigs)

- Vibration testing (3,000 RPM for 100 hours)

- Leak testing (gas tanks: 3 psi air pressure for 24 hours)

Custom Harley Parts Application Fields

- Vintage Restorations: 1936-1969 Knucklehead/Flathead/Shovelhead parts (gas tanks, fenders, engine covers) with authentic materials and finishes.

- Custom Builds: One-off parts for bobbers, choppers, and baggers (stretched gas tanks, 21-inch front fenders, custom handlebars).

- Performance Upgrades: High-flow exhausts, lightweight aluminum engine covers, and reinforced transmission parts for increased horsepower/torque.

- Accessories: Chrome trim, leather-wrapped handlebars, and custom grips that blend vintage style with modern comfort.

Customization Capabilities: From Classic to Radical

Goldcattle delivers tailored solutions for unique Harley builds:

- Vintage authenticity:

- Correct metal gauges (16-gauge steel for 1950s fenders)

- Factory-style welds (stacked dime pattern for 1960s frames)

- OEM color matching (1950s Harley Orange, 1970s Candy Blue)

- Performance enhancements:

- Lightweight aluminum (saves 5-10kg vs. steel parts)

- High-flow exhaust designs (dyno-proven gains)

- Reinforced components (transmission gears, shift forks)

- Custom styling options:

- Tank stretches (2-6 inches) and rake angles (1-5 degrees)

- Handlebar rise/pullback combinations (8-20 inch rise)

- One-off engraving (tank badges, derby covers with custom logos)

Common Customization Questions

- Q: Can you replicate NOS (New Old Stock) parts that are no longer available?

A: Yes—3D scanning of rare NOS parts (e.g., 1948 Panhead rocker boxes) creates digital models, then we machine/reform using original materials (cast iron, 1018 steel) to achieve 99% accuracy. - Q: What’s the lead time for a custom 2.5-inch stretched gas tank?

A: 7 days for design/fitment, 14 days for hand-forming, 10 days for finishing—total 31 days. Rush options for show builds cut lead time by 40% with priority workshop time. - Q: Will custom exhausts fit with my existing engine guards or saddlebags?

A: Yes—we 3D scan your bike’s existing accessories (engine guards, bags) to design exhausts with 10mm+ clearance, verified via test fitting on a duplicate frame. - Q: How to ensure powder coating matches Harley’s factory colors?

A: We use Harley-Davidson-approved powder suppliers and spectrophotometers to measure color (ΔE <1), with a physical sample sent for client approval before full production.

Ready to Build Your Dream Harley?

Goldcattle’s custom Harley parts blend heritage craftsmanship with modern engineering—whether restoring a 1950s classic or building a one-of-a-kind chopper. Our 26-year focus on motorcycle components ensures parts that fit perfectly, perform reliably, and capture your unique style.

Upload your project details (photos, measurements, inspiration) via our online form to receive a design consultation, material recommendations, and quote within 24 hours. Let’s create parts that make your Harley stand out—on the road or at the show.

“Goldcattle’s custom Shovelhead engine covers transformed my 1972 FX—they matched the original casting marks but added modern oiling, solving the leaks that plagued my rebuild. Show-quality work.” — Vintage Harley Restorer Client