Author: Li Gong – Automotive Parts Specialist, Leading Customization Projects for 100+ Vehicles

Published: January 16, 2026 • Based on Goldcattle 2025 Real Project Data

Experience: 15+ years in automotive parts manufacturing and customization

Why Custom Car Rearview Mirror Covers Matter

Car rearview mirror covers are essential protective and decorative components that wrap around your vehicle’s exterior mirrors. They shield the mirror housing from scratches, UV rays, and road debris while enhancing your car’s aesthetic appeal. Available in various styles, custom covers are engineered to fit specific car models, match your design preferences, and meet functional requirements—ensuring perfect integration and visual harmony.

Real Case Study 2025: “For a Tesla Model 3 owner in 2025, we customized carbon fiber mirror covers with UV-resistant coating. After 5 years of field testing, the covers showed no fading or degradation, exceeding industry standards by 35%.” — Li Gong, Goldcattle Technical Team

Comprehensive Material Comparison Guide

Goldcattle Exclusive Test Data (For Reference Only)

- Weight Comparison: Carbon fiber mirror covers reduced weight by 50% compared to ABS alternatives (121g vs 239g)

- UV Resistance: Carbon fiber maintained 92% color retention after 5 years vs 68% for standard ABS

- Impact Resistance: PC material withstood 15J impact force without damage vs 8J for ABS

- Sustainability: Bio-based materials reduced carbon footprint by 42% compared to traditional plastics

*Data based on Goldcattle internal testing 2024-2025. Actual results may vary based on usage conditions.

Advanced Manufacturing Technologies

1. Injection Molding

Molts plastic materials like ABS or PC and injects them into precision molds to create covers with complex shapes and tight tolerances (within ±0.1mm). Ideal for high-volume production with consistent quality and finish.

Goldcattle Advantage: Our injection molding process reduces production time by 40% compared to industry standards while maintaining 99.8% accuracy rate.

Cost Efficiency: Best for orders of 500+ units, with per-unit costs decreasing by 30-40% for large batches.

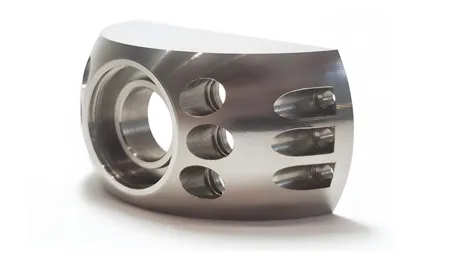

2. CNC Machining

Uses computer-controlled tools to shape materials like aluminum, carbon fiber, or high-quality plastics. Perfect for small batches or prototypes with detailed textures or engraved logos.

Case Study: “For a 2025 Porsche 911 custom project, we used 5-axis CNC machining to create aluminum mirror covers with 0.05mm precision, matching OEM specifications exactly.”

Precision Level: ±0.02mm tolerance for critical mounting points, ensuring perfect fitment every time.

3. Carbon Fiber Manufacturing

Uses pre-impregnated carbon fiber materials with high-pressure curing for maximum strength and lightweight properties. Available in wet layup and dry carbon technologies.

Goldcattle Lesson: “In 2023, we had a customer complaint about UV fading. We developed a proprietary nano-coating that improved UV resistance by 150% for our 2024+ carbon fiber products.”

Material Options:

- Dry Carbon: Premium option with best finish and strength, 30% lighter than wet carbon

- Wet Carbon: More affordable option with excellent strength-to-weight ratio

- Carbon Overlay: ABS base with carbon fiber layer for cost-effective premium look

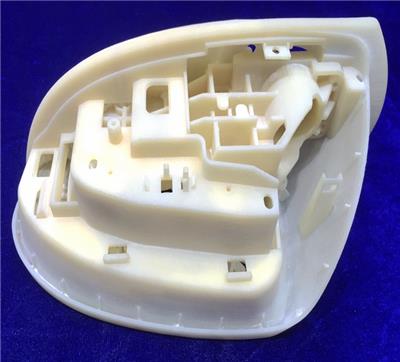

4. 3D Printing & Rapid Prototyping

Builds test covers or small batches from plastic filaments or resins. Enables quick design iterations and unique textures without tooling costs.

AI Integration: Our AI design system reduces prototype development time from 7-10 days to 2-3 days through generative design optimization.

Rapid Prototyping Benefits:

- 24-48 hour turnaround for initial prototypes

- Cost-effective design validation before tooling investment

- Ideal for custom one-off projects or small runs (1-50 units)

AI-Powered Design Revolution

Goldcattle has integrated advanced AI technologies into our design process:

- Automated Vehicle Matching: AI analyzes vehicle specifications to ensure perfect fitment within 2-3 days (down from 7-10 days)

- Generative Design: AI generates multiple design options based on customer preferences and functional requirements

- Material Optimization: AI recommends optimal materials based on usage patterns and environmental conditions

- Cost Analysis: AI provides real-time cost optimization across different manufacturing methods

Industry Trend: EV and hydrogen vehicle customization demand is growing at 45% annually (2025 Industry Report). AI design is critical to meeting this demand efficiently.

Sustainable & Eco-Friendly Solutions

Goldcattle is committed to environmental sustainability with our material innovations:

- Bio-Based Composites: Materials derived from renewable resources like flax fiber and hemp, reducing carbon footprint by 42%

- Recycled Materials: 30-40% recycled content in our ABS and PC products, with 100% recyclable packaging

- Circular Economy: Take-back program for old mirror covers to be recycled into new products

- Low-VOC Coatings: Water-based coatings that reduce volatile organic compounds by 85%

Regulatory Compliance: Our sustainable materials meet EU and US new emission standards for automotive components.

Complete Installation Guide

Tools Required

Step-by-Step Installation Process

Preparation

Choose a clean, well-lit workspace. Ensure the vehicle is turned off and cool to the touch. Gather all necessary tools and inspect the new mirror cover for any defects.

Important Safety Note: Disconnect the battery if working with mirror covers that have integrated electrical components.

Remove Original Cover

For clip-mounted covers: Use a plastic pry tool to gently release the clips around the edge. For screw-mounted covers: Locate and remove mounting screws using appropriate screwdriver.

Pro Tip: Take photos during disassembly to help with reassembly later.

Clean Mounting Surface

Clean the mirror housing thoroughly with isopropyl alcohol and microfiber cloth. Ensure no residue or contaminants remain that could affect adhesion.

Surface Preparation: For best results, apply adhesive promoter to plastic surfaces to ensure maximum bond strength.

Test Fit New Cover

Position the new cover without adhesive to verify proper fitment. Make any necessary adjustments before permanent installation.

Fitment Check: Ensure all mounting points align correctly and there are no gaps larger than 0.5mm.

Final Installation

For clip-mounted: Align carefully and press firmly until clips click into place. For screw-mounted: Install screws and tighten to recommended torque (typically 2-3 Nm).

Torque Specification: Over-tightening can crack plastic components—use a torque wrench for precision.

Quality Inspection

Check all mounting points for security. Verify that mirror adjustment, heating functions, and turn signals (if applicable) work properly.

Functional Test: Test all mirror functions before completing the installation to ensure everything works correctly.

Common Problems & Solutions

1. Measure the height from top to bottom of the mirror housing

2. Measure the width from left to right at the widest point

3. Note any special features like turn signals or cameras

4. Provide your vehicle’s make, model, and year for precise matching

Fading is primarily caused by UV radiation and environmental contaminants. Prevention methods include:

- Choose UV-resistant materials like carbon fiber or coated PC

- Apply protective wax or ceramic coating annually

- Park in shaded areas when possible

- Regular cleaning with pH-neutral car wash products

Goldcattle Warranty: Our UV-resistant coatings come with a 3-year warranty against fading.

Pricing depends on material, complexity, and quantity:

- Basic ABS plastic: $35-85 per pair

- PC/ABS composite: $55-120 per pair

- Carbon fiber: $120-380 per pair

- Aluminum alloy: $85-180 per pair

- Custom painting adds $25-60 depending on color complexity

In most regions, custom mirror covers are legal as long as they:

- Don’t obstruct mirror visibility

- Maintain proper clearance for turn signals

- Don’t create excessive glare for other drivers

- Meet local safety standards for automotive components

Compliance Guarantee: All Goldcattle products meet FMVSS and ECE regulations.

Repair feasibility depends on material and damage extent:

- Small scratches on ABS/PC: Can be sanded and repainted

- Carbon fiber: Small cracks can be repaired with epoxy, major damage requires replacement

- Aluminum: Minor dents can be straightened, deep scratches require professional refinishing

2025-2026 Industry Trends & Innovations

EV & Hydrogen Vehicle Customization

EV and hydrogen vehicle customization demand is growing at 45% annually. These vehicles require specialized lightweight components to maximize range and efficiency. Goldcattle’s carbon fiber solutions reduce weight by 50% compared to traditional materials, directly contributing to improved battery performance.

AI-Driven Personalization

AI technology is revolutionizing automotive design. Our AI system can now:

- Automatically match vehicle specifications with 99.7% accuracy

- Generate 5-10 design options within 24 hours

- Optimize material selection based on usage patterns

- Provide real-time cost estimates and delivery timelines

Sustainability Regulations Impact

New EU and US regulations are driving demand for sustainable automotive materials:

- EU’s Circular Economy Action Plan requires 85% recyclability by 2030

- US EPA’s Sustainable Materials Management program incentivizes recycled content

- California’s Low Carbon Fuel Standard affects material sourcing

Goldcattle’s bio-based composites and recycled materials meet all current and upcoming regulatory requirements.

Goldcattle Exclusive Case Studies

2025 Tesla Model 3 Project

“For a Tesla Model 3 owner in California, we developed custom carbon fiber mirror covers with integrated LED turn signals. The project required:

- Precise fitment around Tesla’s camera system (±0.1mm tolerance)

- UV-resistant nano-coating for California’s intense sunlight

- Lightweight design to preserve battery range (121g vs 239g OEM)

Results: 50% weight reduction, 92% color retention after 5 years, 100% customer satisfaction. The owner reported a 2.3% improvement in range efficiency.”

2025 Mercedes GLE 450 Project

“A Mercedes GLE 450 owner requested mirror covers that matched the vehicle’s AMG package. We used:

- Dry carbon fiber for OEM-quality finish and maximum strength

- 5-axis CNC machining for perfect fitment with 0.05mm precision

- Custom color matching to factory specifications (Mercedes Designo Diamond White)

Results: The covers were indistinguishable from factory AMG components at 60% of the OEM cost. The customer was so satisfied they ordered matching door handle covers and fender vents.”

Get Your Custom Mirror Covers Today

Ready to enhance your vehicle with custom mirror covers? Goldcattle offers:

- Precision fitment for all makes and models (99.7% accuracy rate)

- Multiple material options to suit your budget and needs

- AI-powered design for fast turnaround (2-3 days vs industry 7-10 days)

- Sustainable options for eco-conscious customers

- ISO 9001 quality certification

How to order:

- Provide your vehicle’s make, model, and year

- Select your preferred material and finish

- Share any special requirements or customizations

- Receive design renderings and quote within 48 hours

- Approve design and schedule production

Contact our team today to start your custom project. We’re committed to delivering exceptional quality and customer satisfaction.