Automotive suspension shock absorber dust covers are those flexible, protective sleeves that slide over your car’s shock absorbers. Think of them as tiny raincoats for your shocks—they keep dirt, mud, rocks, and water from getting inside, which helps the shocks last longer and work smoothly. Custom ones are made to fit your specific shocks perfectly, whether you’ve got a fancy sports car, a tough off-road truck, or an old classic that needs a little TLC.

1. Why Bother with Custom Dust Covers?

Stock dust covers are one-size-fits-most, and let’s be real—they often don’t fit your shocks great, especially if you’ve upgraded to bigger, better ones or have a unique suspension setup. Custom covers hug your shocks like a glove, so no gaps for crud to sneak through.

They’re also a lifesaver if you drive in messy conditions: off-roading through mud, city streets full of grit, or rainy climates. And if you’ve got a rare car or a modified ride, good luck finding a stock cover that works—custom is the way to go to keep those expensive shocks protected.

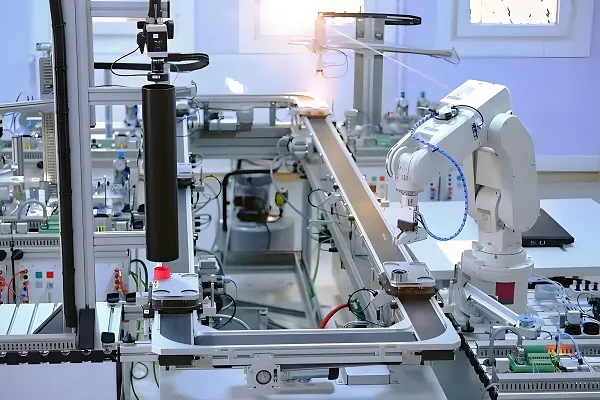

2. How They Make Custom Dust Covers

- Injection Molding: Melted plastic or rubber gets squirted into a mold shaped like your dust cover. Fast, cheap for big batches, and makes super consistent covers.

- Blow Molding: Like making plastic bottles, but for dust covers. A heated tube of material gets blown up inside a mold to take shape—great for flexible, stretchy designs.

- 3D Printing: For one-off or small batches, a 3D printer builds the cover layer by layer. Perfect if you need a quick prototype or have a super unique shape.

- Die Cutting: Thick rubber sheets get sliced into shape with a custom die (like a giant cookie cutter). Good for simple, tough covers that don’t need fancy curves.

3. The Steps to Making Your Custom Cover

- Measure the Shock: We start by measuring your shock absorber—how long it is, how wide, where the curves are. No guesswork here—we need it to fit like a second skin.

- Design It: Using the measurements, we draw up a 3D model. We’ll check for things like how much it needs to stretch when the shock moves, so it doesn’t tear.

- Pick the Material: Rubber? Plastic? We’ll help you choose based on where you drive (more on materials below).

- Make a Mold (if needed): For big orders, we’ll create a mold that matches the design. For small batches, we might skip straight to 3D printing or cutting.

- Produce the Cover: Melt, mold, or print the cover, then trim any extra bits so it looks clean.

- Test It: We’ll slip it over a shock (or a mock-up) to make sure it fits, stretches right, and covers all the important bits. If not, we tweak and try again.

4. Materials Used for Dust Covers

- EPDM Rubber: The workhorse. Super flexible, handles heat and cold like a champ (-40°F to 240°F), and resists water and UV rays. Great for most cars and trucks.

- Polyurethane (PU): Tougher than rubber, less likely to scratch. Good for off-road vehicles where rocks might nudge the cover. A bit stiffer, but lasts longer in rough conditions.

- PVC Plastic: Lightweight and cheap. Works for dry climates but can get brittle in extreme cold. Good for budget builds or temporary covers.

- Neoprene: Like wetsuit material. Stretchy, water-resistant, and soft—great for shocks that move a lot, like on sports cars.

5. Where Custom Dust Covers Shine

- Off-Road Trucks & Jeeps: Mud, rocks, and dirt love to wreck shocks. A custom cover keeps the gunk out, so your shocks don’t seize up mid-trail.

- Sports Cars: Low-slung and fast—their shocks move quickly, so a cover that stretches without tearing is a must. Also keeps road grime off those fancy performance shocks.

- Classic Cars: Old shocks have weird shapes, and stock covers are long gone. Custom ones fit perfectly, keeping your vintage ride’s suspension in top shape.

- Trucks & Work Vehicles: Hauling loads means shocks work hard. A tough cover (like polyurethane) prevents dust from wearing them down prematurely.

- Daily Drivers: Even if you just commute, a custom cover stops salt, rain, and road grit from ruining your shocks—saves you money on replacements.

6. Extra Features for Better Protection

- Reinforced Edges: Thickened rubber or double stitching at the top/bottom where the cover is most likely to stretch or tear.

- UV Resistance: A special coating that stops sunlight from making the cover brittle over time—key if you park outside a lot.

- Lubricated Interior: A slippery coating inside helps the cover slide smoothly over the shock as it moves, so it doesn’t bunch up or wear out.

- Vent Holes (small ones!): Let trapped moisture escape, preventing mold or rust from forming between the cover and the shock.

7. Common Questions About Dust Covers

- Do I really need a dust cover?

If you want your shocks to last. Without one, dirt grinds away at the shock’s seals, leading to leaks and expensive repairs. It’s a cheap insurance policy.

- Can I install it myself?

Absolutely! Most just slip over the shock—no tools needed. If it’s tight, a little soapy water helps it slide on.

- How long do they last?

EPDM or polyurethane covers last 3–5 years (even longer if you clean them occasionally). PVC might need replacing after 1–2 years, especially in harsh weather.

- What if my shocks are modified?

Perfect reason to go custom! Lifted, lowered, or aftermarket shocks rarely fit stock covers. We’ll make one that matches your setup.

- Will it affect how my shocks work?

Nope. Good covers are designed to stretch and move with the shock, so they don’t restrict movement or add extra weight.

Need a dust cover that fits your shocks like it was made for them? Whether you’re slinging mud in a Jeep, cruising in a classic, or just want to protect your daily driver, we’ve got you covered. Drop a comment with your car model, shock type, and where you drive—we’ll help you pick the right material and design. Let’s keep those shocks clean and happy!