Introduction: Your Precision Manufacturing Solutions Expert

Chapter 1: Basic Understanding – Why Choose Stainless Steel CNC Turning?

1.1 Introduction to CNC Turning Technology

1.2 Core Advantages of Stainless Steel Materials

1.3 Synergistic Effect: The Perfect Combination of 1+1>2

- High-precision machining capability: CNC turning can achieve ±0.01mm machining accuracy, fully utilizing the material potential of stainless steel

- Complex shape manufacturing: Capable of processing complex geometric shapes that are difficult to achieve with traditional processes

- Batch consistency: Ensuring complete consistency in dimensional accuracy and performance for each batch of parts

- Design freedom: Providing engineers with greater design space to realize innovative design concepts

Chapter 2: Technical Core – Key Decision Points in the Customization Process

2.1 Stainless Steel Material Selection Guide

|

Grade

|

Main Composition

|

Corrosion Resistance

|

Machinability

|

Strength Level

|

Typical Applications

|

|

303

|

Cr17-19%, Ni8-10%, S≥0.15%

|

Good

|

Excellent

|

Medium

|

Precision gears, valve parts, shaft components

|

|

304

|

Cr18-20%, Ni8-10.5%

|

Excellent

|

Good

|

Medium

|

Food equipment, household appliances, architectural decoration

|

|

304L

|

Cr18-20%, Ni8-12%, C≤0.03%

|

Excellent

|

Good

|

Medium

|

Welded pipes, low-temperature vessels, petrochemical equipment

|

|

316

|

Cr16-18%, Ni10-14%, Mo2-3%

|

Excellent

|

Medium

|

Medium

|

Marine equipment, chemical vessels, medical equipment

|

|

316L

|

Cr16-18%, Ni10-14%, Mo2-3%, C≤0.03%

|

Excellent

|

Medium

|

Medium

|

Semiconductor chambers, medical implants

|

|

416

|

Cr12-14%, S0.15%

|

Fair

|

Excellent

|

High

|

Precision mechanical parts, valves, fasteners

|

|

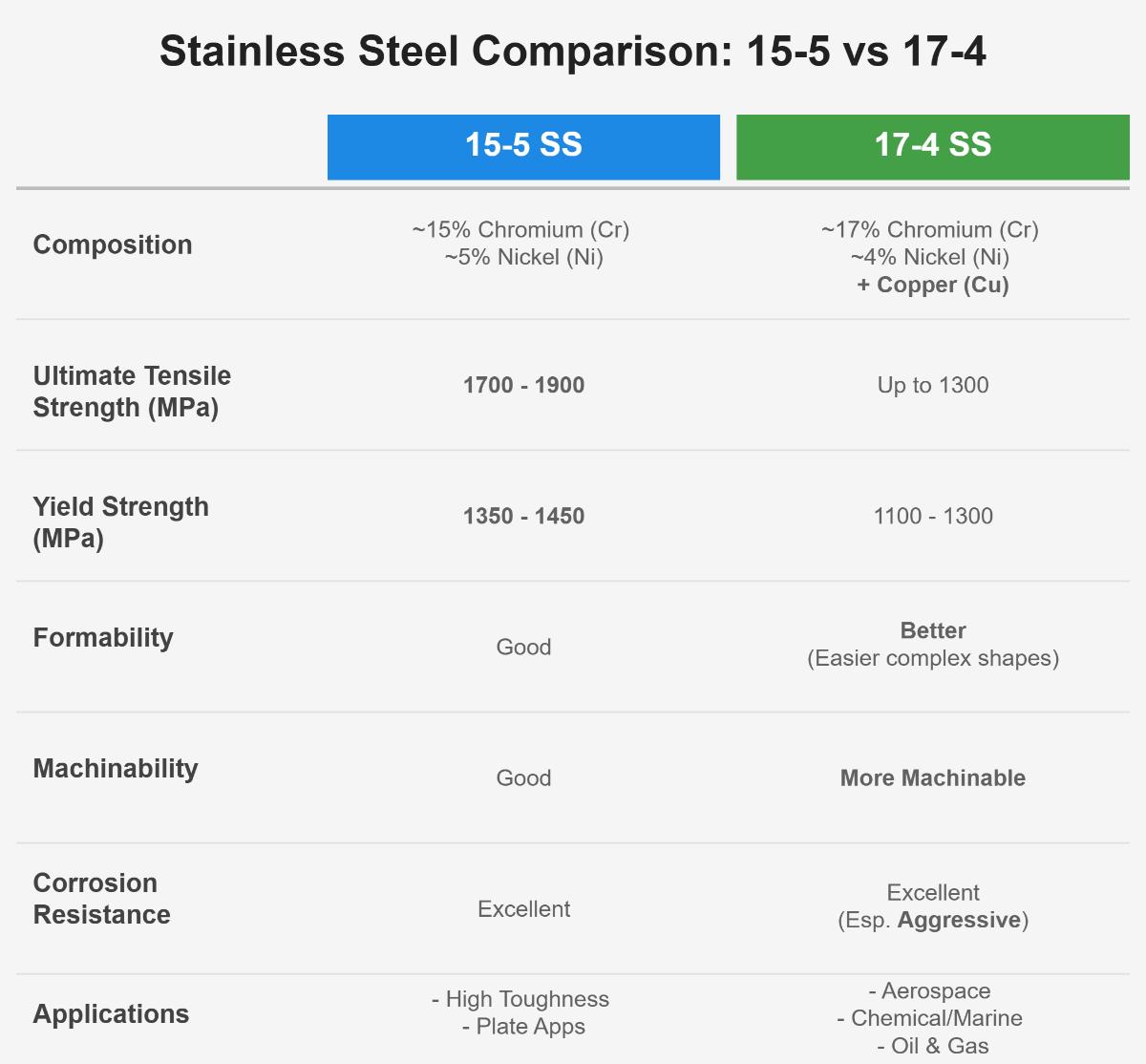

17-4PH

|

Cr15-17.5%, Ni3-5%, Cu3-5%

|

Good

|

Medium

|

Very High

|

Aerospace components, high-strength structural parts

|

- Pursuing ultimate machining efficiency: Choose 303 stainless steel, where sulfur significantly improves cutting performance

- General corrosion resistance requirements: 304 stainless steel is the most cost-effective choice

- Marine or highly corrosive environments: 316/316L stainless steel with molybdenum provides excellent chloride corrosion resistance

- Needing heat treatment strengthening: 17-4PH can achieve high strength above 1300MPa through aging treatment

- Cost-sensitive with moderate corrosion resistance: 416 stainless steel is a good choice

2.2 Key Design and Process Parameters

Tolerance and Precision Control

- Dimensional tolerance: ±0.01mm

- Roundness: 0.005mm

- Cylindricity: 0.01mm/m

- Surface roughness: Ra0.8-3.2μm

Surface Treatment Processes

|

Surface Treatment Process

|

Treatment Effect

|

Main Function

|

Applicable Scenarios

|

|

Passivation Treatment

|

Maintains original color, forms protective film

|

Improves corrosion resistance, extends service life

|

Medical devices, food equipment

|

|

Electroplating Treatment

|

Surface covered with metal layer (e.g., nickel, chromium)

|

Enhances aesthetics, improves wear resistance

|

Decorative parts, friction components

|

|

Sandblasting Treatment

|

Surface forms uniform matte effect

|

Eliminates machining marks, uniform appearance

|

Industrial components, structural parts

|

|

Brushing Treatment

|

Surface forms uniform linear texture

|

Aesthetic decoration, easy to clean

|

Panels, housings, handles

|

|

Mirror Polishing

|

Surface achieves mirror effect

|

Ultimate aesthetics, easy to clean

|

High-end decorative parts, optical components

|

Design Optimization Recommendations

- All external corners are recommended to be designed with R0.5-R1.0mm fillets

- Minimum internal corner radius not less than 0.2mm

- Minimum wall thickness not less than 0.8mm (diameter <20mm)

- Maximum wall thickness to minimum wall thickness ratio not exceeding 3:1

- Avoid sudden wall thickness changes, use gradual transitions

- Thread length not exceeding 1.5 times the thread diameter

- Design undercut at thread start and end

- 6g/6H thread tolerance fit is recommended

2.3 Machining Challenges and Solutions

Work Hardening Problem

- Reasonable cutting parameters: Use lower feed rates and appropriate cutting speeds

- Sharp tools: Use dedicated stainless steel machining tools

- Adequate cooling: Adopt high-pressure coolant system to ensure adequate cooling of the cutting area

Chip Control

- Chip breaker design: Select appropriate tool chip breakers

- Vibration cutting: Adopt micro-vibration cutting technology

- High-pressure flushing: Use high-pressure coolant for forced chip breaking

Chapter 3: Quality Control – How to Ensure Professional Reliability of Parts?

3.1 Testing Equipment and Methods

- Coordinate Measuring Machine (CMM): Tests 3D dimensional accuracy of complex parts

- Optical Projector: Tests 2D contour and shape accuracy

- Micrometers, calipers: Precise measurement of conventional dimensions

- Thread gauges, ring gauges: Thread size and accuracy testing

- Surface roughness tester: Measures surface roughness Ra value

- Metallographic microscope: Observes surface microstructure

- Visual inspection system: Automated appearance defect detection

- Hardness tester: Tests material hardness (HV, HRC)

- Tensile testing machine: Tests material mechanical properties

- Spectrometer: Verifies material chemical composition

- Material chemical composition verification

- Material mechanical property testing

- Material surface quality inspection

- Material dimensional tolerance confirmation

- Complete dimensional inspection

- Geometric tolerance verification

- Surface roughness measurement

- Functional performance testing

- First article inspection report confirmation

- Regular sampling inspection system (1 piece sampled every 10-20 pieces)

- Real-time monitoring of key dimensions

- Machining parameter stability monitoring

- Timely handling of abnormal situations

- Full-dimensional inspection

- Appearance quality inspection

- Surface treatment quality verification

- Final confirmation before packaging

3.3 Standards and Certifications

- ISO 9001: Quality management system certification

- AS9100: Aerospace quality management system

- IATF 16949: Automotive industry quality management system

- ISO 13485: Medical device quality management system

- GB/T 1220: Stainless steel bar standard

- GB/T 1221: Heat-resistant steel bar standard

- ASTM A276: Stainless steel bar and shape standard

- DIN 17440: German stainless steel standard

Chapter 4: Cooperation Process – Clear Path from Inquiry to Delivery

4.1 Standard Cooperation Process

- Provide 2D/3D drawings or samples

- Clarify material requirements and quantity

- Determine precision level and surface treatment

- Evaluate technical feasibility and cost

- Technical team reviews drawings

- Provide detailed quotation

- Confirm delivery cycle and payment terms

- Sign technical agreement

- Produce first article sample

- Conduct First Article Inspection (FAI)

- Customer confirms sample quality

- Determine final production plan

- Raw material procurement and inspection

- Mass production and process monitoring

- Product quality inspection

- Packaging and labeling

- Shipping according to agreed method

- Provide quality inspection report

- After-sales service and technical support

- Customer satisfaction survey

4.2 Key Success Factors

- Provide complete 2D/3D drawings (recommended formats: PDF, DWG, IGES, STEP)

- Clearly mark key dimensions and tolerance requirements

- Detailed description of surface treatment and packaging requirements

- Establish dedicated project communication group

- Regular production progress reporting

- Timely handling of technical issues and changes

- Sample production: 3-7 working days

- Small batch production: 5-15 working days

- Mass production: 15-30 working days

- Emergency orders: Expedited service available

Chapter 5: Industry Application Case Analysis

5.1 Medical Device Industry

- Material Selection: 316L stainless steel

- Precision Requirement: ±0.005mm

- Surface Treatment: Passivation treatment

- Quality Standard: ISO 13485 certification

- Key Challenges: Biocompatibility, cleanliness requirements

5.2 Aerospace Industry

- Material Selection: 17-4PH stainless steel

- Precision Requirement: ±0.003mm

- Surface Treatment: Natural passivation

- Quality Standard: AS9100 certification

- Key Challenges: High strength, lightweight, reliability

5.3 Food Processing Equipment

- Material Selection: 304 stainless steel

- Precision Requirement: ±0.01mm

- Surface Treatment: Electrolytic polishing

- Quality Standard: FDA certification

- Key Challenges: Hygiene standards, corrosion resistance

5.4 Electronic Communication Industry

- Material Selection: 303 stainless steel

- Precision Requirement: ±0.008mm

- Surface Treatment: Nickel plating

- Quality Standard: RoHS compliance

- Key Challenges: Miniaturization, high precision, large quantities

Chapter 6: Cost Control and Optimization Strategies

6.1 Cost Composition Analysis

- Raw material price fluctuations

- Material utilization rate

- Scrap disposal cost

- Equipment depreciation

- Tool consumption

- Labor cost

- Energy consumption

- Testing equipment investment

- Testing labor cost

- Rework and scrap cost

- Project management cost

- Quality system maintenance

- After-sales service cost

6.2 Cost Optimization Strategies

- Reasonable selection of material grades

- Optimization of part structure design

- Selection of appropriate tolerance levels

- Simplification of surface treatment requirements

- Optimization of cutting parameters

- Improvement of tool life

- Reduction of processing steps

- Improvement of production efficiency

- Reasonable arrangement of production batches

- Optimization of procurement strategy

- Improvement of equipment utilization

- Reduction of changeover costs

Chapter 7: Future Development Trends and Technological Innovation

7.1 Technology Development Trends

- AI-driven process parameter optimization

- Application of digital twin technology

- Adaptive control machining systems

- Predictive maintenance technology

- Nanoscale machining accuracy

- Ultra-precision testing technology

- Multi-axis linkage machining

- Composite machining technology

- Environmentally friendly cutting fluids

- Energy-saving machining processes

- Waste recycling and utilization

- Clean production technology

7.2 Application Field Expansion

- New energy vehicle components

- Photovoltaic equipment precision parts

- Energy storage equipment structural parts

- Hydrogen energy equipment key components

- Industrial robot precision parts

- 3C equipment structural parts

- Precision instrument components

- Smart equipment core components

Conclusion: Choose Professional Partners to Create a Precision Manufacturing Future

- 15 years of professional experience: Focused on stainless steel precision machining for 15 years

- 80+ advanced equipment: Possessing imported CNC lathes, machining centers, and other equipment

- ISO 9001 certification: Complete quality management system

- 24-hour rapid response: Professional technical team at your service anytime

- One-stop solution: Full-process service from design optimization to final delivery

- Upload drawings for quotation: Send your 2D/3D drawings to our technical email

- Technical consultation hotline: Call our technical hotline for professional technical advice

- Factory visit: Welcome to make an appointment to visit our production workshop and testing center

- Sample production: Rapid sample production to verify product quality and technical solutions