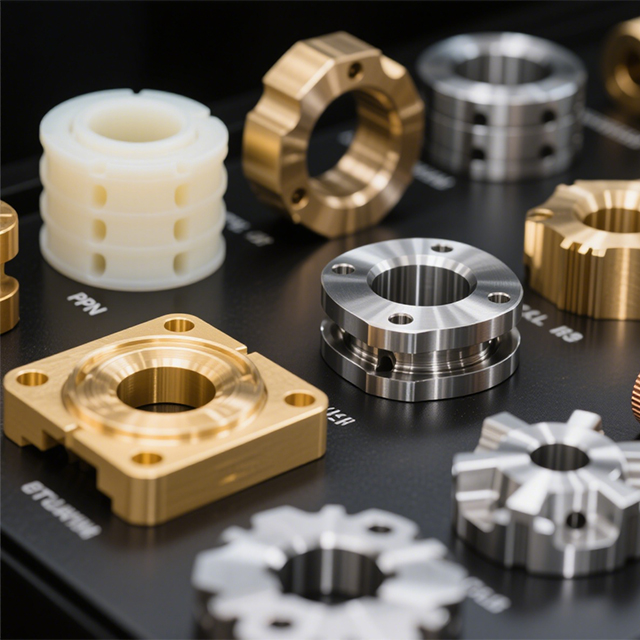

Custom OEM CNC Machining | Plastic & Metal Parts

Materials: POM, PEEK, ABS, Stainless Steel, Titanium, Brass, Copper, Aluminum

Process: Precision CNC Machining (Milling, Turning, Drilling)

Tolerance: ±0.01mm (High Precision)

Surface Finish: Anodizing, Polishing, Plating, Sandblasting

Applications: Industrial, Medical, Automotive, Electronics, Aerospace

Description

Discover our premium custom OEM CNC machining services, delivering precision parts in plastic and metal for diverse industries. We combine advanced technology with expert craftsmanship to turn your designs into high-quality components.

Our material range meets every requirement: Engineering plastics like POM (wear-resistant, low friction) and PEEK (high-temperature resistance, chemical stability) excel in demanding environments. ABS offers excellent impact resistance for structural parts. For metals, we provide stainless steel (corrosion-resistant), lightweight titanium (high strength-to-weight ratio), conductive brass/copper, and versatile aluminum (easy machining, good heat dissipation). All materials comply with international standards for reliability.

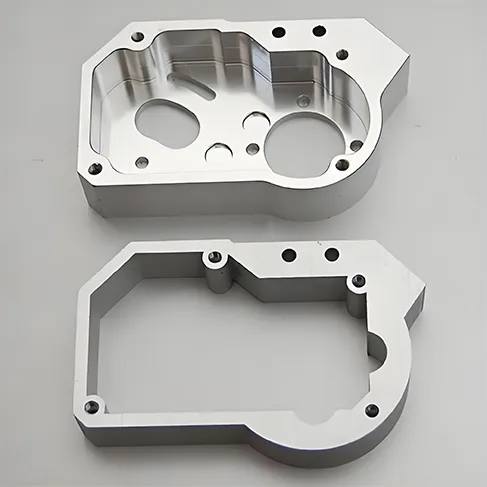

Precision is our hallmark. Our CNC machining processes—including milling, turning, and drilling—achieve tight tolerances of ±0.01mm, ensuring perfect fit and function. Advanced CNC systems handle complex geometries, from simple brackets to intricate mechanical parts, with consistent accuracy across production runs. We support both prototyping and mass production, maintaining the same high standards at any scale.

Our streamlined workflow guarantees quality: Start with your CAD files or samples—our engineering team conducts DFM (Design for Manufacturability) analysis to optimize designs for cost and precision. Next, we select the right material and program CNC machines for production. During machining, real-time monitoring ensures dimensional accuracy. Post-processing includes surface treatments (anodizing for aluminum, plating for metals) to enhance durability and aesthetics. Final inspection uses 3D scanning and coordinate measuring machines (CMM) to verify every specification.

These parts power critical applications across industries: Industrial machinery relies on our durable components for gears and brackets. Medical devices use our biocompatible parts (titanium, PEEK). Automotive and electronics benefit from our precision connectors and heat sinks. Aerospace trusts our high-strength metal parts for performance under extreme conditions.

What makes us stand out? Full customization—we adapt to your unique designs, material preferences, and volume needs. Fast turnaround (3-5 days for prototypes, 10-20 days for bulk orders) keeps your projects on schedule. Our quality control system ensures zero defects, backed by material certificates and inspection reports.

Partner with us for reliable CNC machining solutions. Whether you need a single prototype or large-scale production, we deliver consistent quality at competitive prices. Order now to get a free design consultation and quote within 24 hours. Experience hassle-free manufacturing where precision meets efficiency—your perfect parts are just a design away!