Custom UPE wear-resistant Special-shaped parts (including mechanical slides, gears, and lathe-turned components) are precision-machined components made from ultra-high molecular weight polyethylene. These specialized parts deliver exceptional wear resistance and low friction in demanding mechanical applications, with customizable geometries to fit unique equipment requirements across industries.

Applications, Common Sizes & Product Features

Typical Applications

Widely used in conveyor systems (chain guides, slider beds), mining machinery (wear liners, pulley components), construction equipment (bushings, spacers), food processing (gear drives, guide rails), and material handling (cam followers, bearing components). Ideal for applications requiring abrasion resistance and self-lubrication without metal-to-metal contact.

Common Specifications

- Dimensions: Length 10mm-1500mm, width 5mm-800mm, thickness 2mm-300mm

- Tolerance Range: ±0.05mm (for precision components), ±0.1mm (for large structural parts)

- Gear Parameters: Module 0.5-10, number of teeth 10-120, pressure angle 20° (standard)

- Surface Finish: Ra 0.8-3.2μm (depending on functional requirements)

- Operating Temperature Range: -20°C to 80°C (continuous use)

Key Product Features

- Exceptional Wear Resistance: 6-8 times more wear-resistant than carbon steel; 3-4 times better than nylon in dry sliding conditions.

- Low Friction Coefficient: 0.05-0.1 (dry), reducing energy consumption by 15-20% compared to metal components.

- High Impact Strength: Absorbs impact energy without cracking (impact strength ≥150kJ/m² at 23°C).

- Chemical Resistance: Resists corrosion from acids, alkalis, and most organic solvents (except strong oxidizing agents).

- Self-Lubricating: Eliminates need for frequent lubrication, reducing maintenance costs by 30%+.

- Lightweight: Density 0.93-0.94 g/cm³ (70% lighter than steel, 40% lighter than aluminum).

Alternative Processable Materials & Their Features

- HDPE (High-Density Polyethylene): Cost-effective alternative with good chemical resistance but lower wear resistance (50% of UPE). Suitable for low-load, non-abrasive applications.

- POM (Polyoxymethylene): Higher rigidity and dimensional stability than UPE, with better creep resistance. Ideal for precision gears requiring tight tolerance (tolerance down to ±0.02mm).

- PTFE (Polytetrafluoroethylene): Lower friction coefficient (0.02-0.04) but lower wear resistance than UPE. Used in high-temperature (up to 260°C) or food-grade applications.

- Nylon 6/6: Higher tensile strength than UPE (80MPa vs. 40MPa) but inferior wear resistance. Better for applications requiring structural strength with moderate abrasion.

- PEEK (Polyether Ether Ketone): High-temperature resistance (up to 260°C) and chemical resistance, but 5-8 times more expensive than UPE. Used in aerospace/medical high-performance applications.

Manufacturing Process

- Material Selection & Preparation: Choose UPE rods/sheets with appropriate molecular weight (3-6 million g/mol) based on wear requirements; cut blanks to rough size with 5-10mm machining allowance.

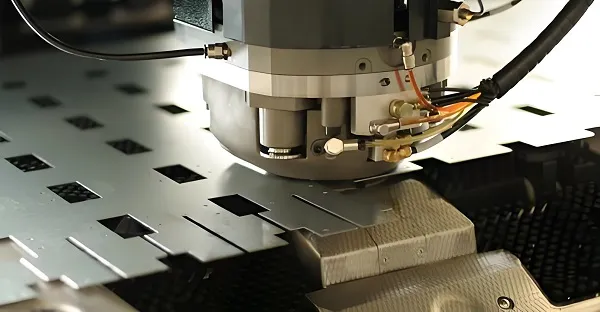

- Precision Machining:

-

- Turning: CNC lathes for cylindrical parts (shafts, bushings) with live tooling for features.

-

- Milling: 3-axis/5-axis CNC mills for complex Special-shaped geometries (slides, gears, irregular shapes).

-

- Grinding: Surface grinders for flatness control (≤0.01mm/m) and precision finishes.

- Heat Treatment: Stress-relief annealing at 80-100°C for 2-4 hours to reduce machining-induced stresses.

- Surface Treatment: Optional anti-static coating or bonding preparation (sandblasting) for composite assemblies.

- Quality Inspection: Dimensional verification with CMM (coordinate measuring machine), surface finish testing, and wear resistance sampling.

Manufacturing Challenges

- Thermal Deformation: UPE’s low thermal conductivity (0.4 W/(m·K)) causes heat buildup during machining, leading to dimensional shifts. Requires controlled cutting speeds (100-300m/min) and coolant use.

- Material Viscoelasticity: UPE’s tendency to “spring back” after machining demands precise tool path compensation (typically 0.03-0.05mm oversize machining).

- Large Part Stability: Maintaining flatness in parts over 500mm length requires specialized fixturing and sequential machining passes.

- Sharp Feature Preservation: Thin walls (<3mm) and fine gear teeth are prone to chipping; requires high-speed steel (HSS) or carbide tools with optimized rake angles (10-15°).

- Consistent Wear Performance: Achieving uniform material properties across large batches requires strict raw material control (molecular weight variation ≤5%).

Customization Process

- Requirement Collection: Customers provide 2D/3D drawings or sample parts, specifying operating conditions (load, speed, environment, mating materials).

- Material & Design Consultation: Our engineers recommend optimal UPE grade and machining approach within 2 working days, including DFM (Design for Manufacturability) feedback.

- Prototype Production: Manufacture 1-3 prototypes using CNC machining, with delivery in 5-7 working days.

- Testing & Validation: Conduct dimensional inspection, friction coefficient testing, and wear simulation; adjust machining parameters if needed.

- Bulk Production: Full-scale manufacturing with 10-15 day lead time (depending on quantity), including 100% dimensional checks for critical features.

Frequently Asked Questions

- Q: Why is my UPE part showing faster wear than expected?

A: Possible causes include operating beyond 80°C (softens material), excessive load (exceeding 10MPa contact pressure), or abrasive particle contamination. Check mating surface finish (should be Ra ≤1.6μm).

- Q: Can UPE parts replace metal in high-load applications?

A: For static loads up to 20MPa or dynamic loads up to 10MPa, yes. For higher loads, consider metal-UPE composites or reinforced UPE grades with glass fiber (increases load capacity by 40%).

- Q: How to improve dimensional stability in large UPE parts?

A: Specify stress-relief annealing after machining and avoid sudden temperature changes in operation. We recommend designing with 0.1% linear expansion allowance for parts over 300mm.

- Q: Are UPE parts suitable for food contact applications?

A: Yes—food-grade UPE complies with FDA 21 CFR 177.2600 and EU 10/2011 standards, with no toxic leaching and easy cleanability (smooth surfaces prevent bacterial growth).

Need durable, low-friction custom parts for your machinery? Goldcattle specializes in UPE wear-resistant Special-shaped components—slides, gears, and precision machined parts tailored to your specs. Our UPE parts deliver 6x better wear resistance than steel, with self-lubricating properties that cut maintenance costs. From small gears (module 0.5) to large slides (1500mm), we achieve ±0.05mm precision with CNC machining. Choose from UPE, POM, nylon, or PTFE based on your needs. Have a drawing or sample? Leave us a message through our contact form, and our engineers will respond within 24 hours with material recommendations and a quote. Visit https://www.xmgoldcattle.com/ to start your custom UPE part project today!