Custom stainless steel pulleys are precision-engineered components designed for power transmission and load handling in engineering machinery. These durable wheels with grooved rims guide cables, ropes, or belts, distributing loads evenly while reducing friction. Tailored to specific machinery requirements, they offer enhanced corrosion resistance and strength for heavy-duty industrial applications.

Applications, Common Sizes & Product Features

Typical Applications

Widely used in construction machinery (cranes, excavators), material handling equipment (hoists, winches), agricultural machinery (harvesters, tractors), and industrial lifting systems. Critical for applications requiring reliable load movement, including lifting heavy materials (5-500 tons), tensioning cables, and facilitating smooth mechanical motion in harsh working environments.

Common Specifications

- Diameter Range: 50mm-800mm (standard: 100mm-500mm)

- Groove Dimensions: Width 10mm-50mm, depth 5mm-30mm; compatible with cables/belts of Φ6mm-Φ40mm

- Bore Size: 20mm-150mm (tolerance H7 for shaft fit)

- Wall Thickness: 8mm-50mm (depending on load capacity)

- Load Capacity: 5kN-500kN (static), 3kN-300kN (dynamic)

- Tolerance: Diameter ±0.1mm, groove position ±0.05mm

Key Product Features

- High Strength: 304/316 stainless steel construction with tensile strength 515-690MPa, withstands 1.5x rated load without deformation.

- Corrosion Resistance: Resists rust and chemical corrosion in humid, dusty, or outdoor environments; 316 variants survive 1000+ hours in salt spray tests (ASTM B117).

- Low Friction: Precision-machined grooves (Ra ≤1.6μm) reduce cable/belt wear by 25-30% compared to standard pulleys.

- High Wear Resistance: Hardened groove surfaces (HRC 40-45) extend service life to 10,000+ operating hours in standard conditions.

- Dimensional Stability: Maintains tolerance under temperature fluctuations (-20°C to 120°C), ensuring consistent performance.

Alternative Processable Materials & Their Features

- Carbon Steel (S45C): Cost-effective for low-corrosion environments; high tensile strength (600-700MPa) but requires painting/galvanizing for rust protection. Suitable for indoor, dry applications with moderate loads (≤100kN).

- Ductile Iron (GGG50): Excellent impact resistance (15-20J at -20°C) and vibration damping; 30% cheaper than stainless steel but 20% heavier. Ideal for shock-loaded applications like construction cranes.

- Alloy Steel (42CrMo): Superior strength (tensile strength 1000-1200MPa) after heat treatment; handles extreme loads (500kN+). Used in heavy-duty mining machinery but requires corrosion protection.

- Aluminum Alloy (6061-T6): Lightweight (2.7g/cm³ vs. steel’s 7.8g/cm³) for portable equipment; good corrosion resistance but lower load capacity (max 50kN). Suitable for agricultural or light construction machinery.

Manufacturing Process

- Material Preparation: Cut stainless steel round bars/plates to blank size using plasma cutting or sawing; verify material certification (3.1B reports for chemical composition).

- Rough Forming:

-

- Forged pulleys (diameter >300mm): Hot forging at 1100-1200°C to shape the rim and hub, improving grain structure.

-

- Machined pulleys (diameter ≤300mm): CNC turning to rough dimensions with 5-10mm machining allowance.

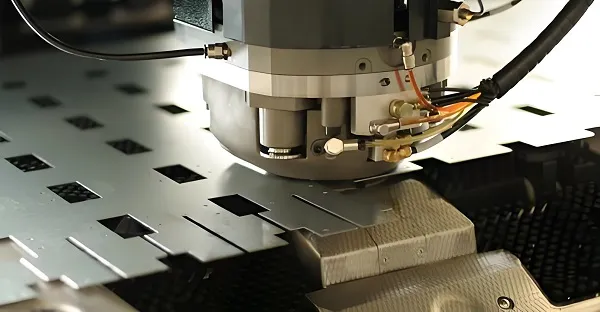

- Precision Machining:

-

- CNC turning for outer diameter, bore, and hub faces (tolerance ±0.05mm).

-

- CNC milling or grinding for groove profiles, ensuring consistent shape and surface finish (Ra ≤1.6μm).

- Heat Treatment: Solution annealing (1050-1100°C) for stainless steel to relieve internal stresses; optional surface hardening for grooves (HRC 40-45).

- Surface Treatment: Passivation (nitric acid bath) to enhance corrosion resistance; electropolishing for high-precision applications (Ra ≤0.8μm).

- Assembly & Testing: Install bearings/bushings (if integrated); conduct static load testing (1.5x rated load for 10 minutes) and dimensional inspection with CMM.

Manufacturing Challenges

- Groove Precision: Maintaining consistent groove depth and angle (±0.05mm) across large diameters requires advanced CNC grinding with real-time measurement systems—even minor deviations cause uneven cable wear.

- Weld Integrity (for split pulleys): Joining pulley halves requires TIG welding with minimal heat input to prevent distortion; 100% ultrasonic testing ensures no internal defects.

- Balancing Large Pulleys: Pulleys over 500mm diameter must be dynamically balanced (G6.3 grade) to reduce vibration; requires precision balancing machines and careful material removal.

- Corrosion Resistance After Machining: Machining can damage the passive chromium layer; strict post-machining passivation (20-30% nitric acid, 30-60 minutes) is critical for 304/316 variants.

- Thin-Wall Stability: Pulleys with large diameter-to-wall-thickness ratios (>20:1) are prone to deformation during machining; requires specialized fixturing and slow feed rates.

Customization Process

- Requirement Collection: Customers provide application details (load capacity, cable type, environment), dimensions (diameter, bore, groove size), and standards (ISO, ASTM, or custom).

- Engineering Design: 3D modeling (SolidWorks) and FEA simulation to verify strength and deflection; material recommendation based on environment/load within 2 working days.

- Prototype Production: Manufacture 1-2 prototypes using CNC machining/forging; include material test reports and dimensional inspection. Delivery in 7-14 days.

- Testing & Validation: Conduct load testing, wear simulation, and corrosion testing (if applicable); adjust design (e.g., increase wall thickness, modify groove profile) based on results.

- Mass Production: Full-scale manufacturing with batch testing (10% sampling for load capacity); lead time 20-30 days for orders <50 units.

Common Questions

- Q: Why is my pulley causing excessive cable wear?

A: Likely due to mismatched groove size (cable diameter should be 85-90% of groove width) or rough groove surface (Ra >3.2μm). Check groove dimensions and consider re-grinding for smoother finish.

- Q: How to calculate the maximum load for a custom pulley?

A: Load capacity depends on material strength, diameter, and wall thickness. Our formula: Load (kN) = (π × diameter × wall thickness × material tensile strength) / 8 × safety factor (1.5).

- Q: Can stainless steel pulleys be used in marine environments?

A: Yes—specify 316 stainless steel with electropolishing; it resists saltwater corrosion (survives 2000+ hours in salt spray tests) and outlasts 304 by 3-5x in marine conditions.

- Q: When should I choose a forged vs. machined pulley?

A: Forged pulleys (diameter >300mm) offer better strength for heavy loads (>200kN). Machined pulleys are more cost-effective for smaller sizes (<300mm) or complex groove profiles.

Need custom stainless steel pulleys that stand up to tough engineering machinery demands? Goldcattle specializes in tailored pulleys for cranes, excavators, and lifting systems—from 50mm to 800mm diameter, 5kN to 500kN load capacity. Our 304/316 stainless pulleys deliver 25% less cable wear, 10,000+ hour service life, and superior corrosion resistance. Whether you need specific grooves, bore sizes, or high-load designs, we precision-engineer to your specs. Have dimensions, load requirements, or environment details? Leave us a message via our contact form, and our engineers will respond within 24 hours with a personalized quote and design recommendations. Visit https://www.xmgoldcattle.com/ to start your custom pulley project today!