CNC parts for Ducati motorcycles are precision components crafted using Computer Numerical Control machining technology. These parts, which can range from engine components to aesthetic upgrades, are designed to meet the high – performance and stylish standards of Ducati bikes. They offer enhanced durability, better fitment, and often improved functionality compared to stock parts, whether for racing, street riding, or customizing Ducati motorcycles.

1. Types of CNC Parts for Ducati

Engine Components

- Cylinder Heads: CNC – machined cylinder heads for Ducati engines are designed to optimize the intake and exhaust flow. By precisely shaping the ports and valve seats, these heads can significantly improve the engine’s breathing. For example, in high – performance Ducati models like the Panigale V4, CNC – ported cylinder heads can increase horsepower by ensuring a more efficient fuel – air mixture combustion. The tolerances in CNC – machined cylinder heads are extremely tight, often within ±0.01mm, which helps in better sealing and reduced gas leakage.

- Crankshafts: Ducati’s high – revving engines demand extremely balanced crankshafts. CNC – lathed crankshafts can be crafted with precision to reduce vibration. The material used, often high – strength steel, is carefully machined to the exact specifications required for the engine’s performance. A well – balanced CNC – made crankshaft can enhance the engine’s smoothness at high RPMs, which is crucial for both street – legal Ducatis and those used in racing.

- Pistons: CNC – manufactured pistons for Ducati engines are designed to have a perfect fit within the cylinders. They are made from lightweight yet strong materials such as aluminum alloys. The precise machining of the piston skirts and the piston crown ensures minimum friction and maximum power transfer. In racing Ducatis, where every bit of performance matters, custom – CNC pistons can be designed to withstand the extreme pressures and temperatures generated during high – speed runs.

Suspension and Chassis Parts

- Suspension Link Arms: Brands like CNC Racing offer suspension link arms for Ducati models such as the Panigale 1299/1199/959/899, V2, and Superleggera. These arms are machined from 7075 aluminum, which provides a good balance between strength and weight. By replacing the stock cast link arms, the rear – end feedback can be improved as the CNC – machined ones are stiffer. They are also anodized in colors like red, gold, or black, adding a touch of style.

- Frame Brackets: CNC – machined frame brackets are used to ensure precise alignment of various components on the Ducati chassis. Whether it’s mounting the suspension, engine, or body panels, these brackets are made to exact specifications. In custom Ducati builds, frame brackets can be designed to fit non – standard components, allowing for greater customization and fine – tuning of the bike’s handling characteristics.

- Fork Sliders: Fork sliders play a crucial role in the smooth operation of the front suspension. CNC – machined fork sliders for Ducati motorcycles are made to have a very smooth surface finish, reducing friction as the forks compress and extend. They are often made from high – quality materials like aluminum alloys or steel, depending on the intended application and the level of performance required.

Drivetrain Parts

- Sprockets: CNC – cut sprockets for Ducati bikes, such as the CNC Racing Ducati ring gear with 5 – hole and 520 pitch, are available in different tooth counts (ranging from 39 – 47 teeth). These sprockets are machined from light alloy billets and then given a black anodized hard – surface finish. They ensure uniform tooth spacing, which reduces chain wear and improves power transfer. In racing, the right choice of sprocket ratio, made possible by CNC – machined sprockets, can significantly impact acceleration and top speed.

- Transmission Gears: CNC – machined transmission gears for Ducati motorcycles are made to have extremely tight meshing tolerances. This reduces backlash, ensuring smooth shifting. High – strength materials are used to withstand the high torque generated by Ducati engines. In high – performance Ducati models, the precision – made transmission gears contribute to seamless gear changes, which are essential for maintaining speed and power during acceleration.

Aesthetic and Custom Parts

- Handlebars: CNC – machined handlebars for Ducati can be ergonomically designed to provide a more comfortable grip for the rider. They can be made from aluminum alloys and come in various shapes and finishes. Some handlebars may also have CNC – machined lever pivots, which offer a more precise feel when operating the brakes and clutch. In custom Ducati builds, unique handlebar designs can enhance the overall look and feel of the bike.

- Body Panels and Trim: Carbon fiber or aluminum body panels, such as fairings and fuel tank covers, are often CNC – machined for Ducati motorcycles. These parts not only reduce the overall weight of the bike but also add to its aerodynamic efficiency. For example, CNC – machined carbon fiber fairings on the Ducati Panigale V4 are designed to minimize drag at high speeds, while also providing a sleek and stylish appearance.

2. Materials Used in CNC Ducati Parts

Aluminum Alloys

- 6061 Aluminum: This alloy is widely used for non – load – bearing parts such as covers, brackets, and some aesthetic components in Ducati motorcycles. It is relatively easy to machine, which makes it cost – effective for OEM production. Its moderate strength and good corrosion resistance make it suitable for parts that do not experience extreme stresses. For example, many engine covers and some handlebar components on Ducati bikes are made from 6061 aluminum.

- 7075 Aluminum: Preferred for high – stress components like suspension link arms, swingarms, and some engine mounts in Ducati models. It has a high tensile strength (around 570 MPa) and excellent fatigue resistance. In racing Ducatis, where components need to withstand extreme forces, 7075 aluminum CNC – machined parts are commonly used. However, due to its hardness, it requires more specialized tooling and machining techniques compared to 6061 aluminum.

Steels

- 4130 Chromoly Steel: Used for frame components and some drivetrain parts in Ducati motorcycles, especially in off – road and vintage – style builds. It offers a good strength – to – weight ratio and is highly weldable. This makes it suitable for fabricating custom frames or modifying existing ones. For example, in some custom – built Ducati scramblers, 4130 chromoly steel is used to create a more robust and durable frame structure.

- Stainless Steel (304/316): Stainless steel is often used for parts that are exposed to harsh environments, such as exhaust flanges, fasteners, and components on Ducati motorcycles used in marine or muddy terrains. Its corrosion – resistant properties ensure the longevity of these parts. Stainless steel parts are also used in areas where a clean and rust – free appearance is desired, like some decorative trim pieces.

Titanium Alloys (Ti – 6Al – 4V)

Titanium alloys are a premium choice for high – performance Ducati parts such as valves, exhaust headers, and some critical engine components. They offer an exceptional strength – to – weight ratio and excellent heat resistance. Although titanium is more expensive and harder to machine compared to other materials, its use in Ducati bikes can significantly reduce the overall weight of the bike, which improves acceleration, handling, and fuel efficiency. For example, in high – end Ducati racing models, titanium valves can allow for higher engine RPMs due to their lightweight nature.

Carbon Fiber Composites

Carbon fiber composites are increasingly being used in CNC – machined parts for Ducati motorcycles, especially in racing and high – performance street models. Parts like fairings, fenders, and some body panels are made from carbon fiber. It offers ultra – lightweight properties with high rigidity, which is crucial for aerodynamic performance. Carbon fiber parts can be CNC – machined to precise shapes, allowing for optimal aerodynamic design. In MotoGP – inspired Ducati models, carbon fiber fairings are designed to reduce drag and improve high – speed stability.

3. Manufacturing Process of CNC Ducati Parts

Design and Programming

Engineers start by using CAD (Computer – Aided Design) software like SolidWorks or Fusion 360 to create detailed 3D models of the parts. They take into account the specific requirements of the Ducati motorcycle, such as the engine’s performance needs, the bike’s handling characteristics, and the aesthetic design. Once the design is complete, CAM (Computer – Aided Manufacturing) software is used to convert the CAD model into toolpaths. The CAM software optimizes the feeds and speeds based on the material being used. For example, when machining aluminum parts, the spindle speed may be set between 10,000 – 20,000 RPM, and the feed rate could range from 500 – 2000 mm/min.

Material Preparation

The raw materials, whether it’s an aluminum billet, a steel bar, or a carbon fiber pre – form, are prepared before machining. They are cut to near – net shape to minimize the amount of material that needs to be removed during CNC machining, which saves time and reduces waste. For high – strength materials like some steels and titanium alloys, pre – heat treatment such as annealing may be carried out to soften the material, making it easier to machine.

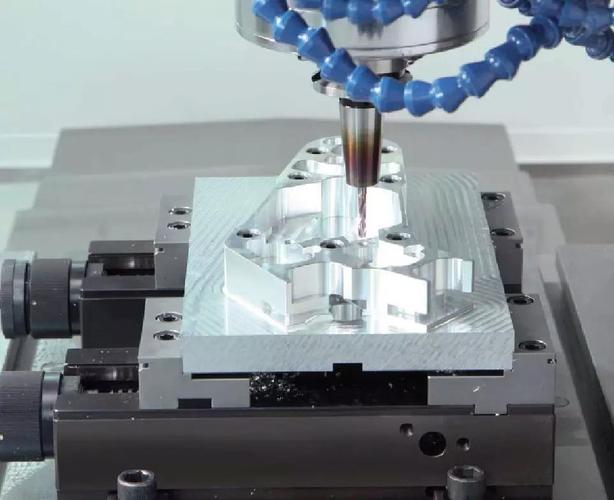

CNC Machining

- Roughing: In the roughing stage, large end mills are used to remove the bulk of the material quickly. This stage prioritizes speed to reduce the overall machining cycle time. For example, a 10 – 20 mm end mill may be used to rapidly remove material from an aluminum billet when manufacturing a Ducati engine block.

- Finishing: After roughing, smaller tools, typically 3 – 6 mm carbide end mills, are used for the finishing operations. This is where the tight tolerances and smooth surface finishes are achieved. For parts like cylinder heads, the finishing process ensures that the surface finish is within the range of Ra < 1.6μm, which is crucial for proper sealing and engine performance.

- Multi – Axis Machining: Many Ducati parts, especially those with complex geometries such as suspension link arms or some engine components, require multi – axis machining. 4 – axis or 5 – axis CNC machines are used to create these complex 3D shapes in a single setup. This reduces errors that could occur from multiple operations and ensures a more precise final product.

Post – Processing

- Heat Treatment: Parts made from materials like steel, such as sprockets or some engine components, may undergo heat treatment processes such as quenching and tempering. This hardens the surface of the part, increasing its wear resistance. The hardness of the part can be adjusted to a specific Rockwell hardness scale (e.g., 50 – 60 HRC) depending on its application.

- Surface Finishing: Anodizing is a common surface – finishing process for aluminum parts. It not only adds corrosion resistance but also provides a decorative finish in various colors. Powder coating is used for steel parts to enhance their durability and appearance. Polishing is often carried out on parts where a smooth surface is required to reduce friction, such as in some moving engine components.

Inspection

CNC – machined Ducati parts undergo strict inspection procedures. Coordinate Measuring Machines (CMMs) are used to verify the dimensions of the parts, ensuring they meet the tight tolerances specified in the design. Optical comparators are used to check the surface finish. For critical parts like engine valves or transmission gears, non – destructive testing methods such as X – ray or ultrasonic testing may be employed to detect any internal defects that could affect the performance and safety of the motorcycle.

4. Applications in Different Ducati – Related Scenarios

OEM Production

In the original equipment manufacturing (OEM) of Ducati motorcycles, CNC – machined parts play a crucial role. Parts like engine blocks, transmission gears, and suspension components are often CNC – manufactured. The precision of CNC machining ensures consistency across thousands of units produced. This reduces the likelihood of warranty issues due to part failures caused by manufacturing inaccuracies. For example, the CNC – machined engine blocks in Ducati’s production – line motorcycles are made to exact specifications, which helps in maintaining the engine’s performance and reliability.

Aftermarket Performance Upgrades

The aftermarket for Ducati motorcycles is filled with CNC – made performance – upgrade parts. Companies like Akrapovič and Yoshimura offer CNC – machined exhaust headers and intake systems. These parts are designed to optimize the airflow in the engine, which can boost horsepower by 10 – 20% in street – legal Ducatis. Suspension upgrade parts, such as CNC – machined shock absorbers and fork cartridges, can improve the bike’s handling and ride quality. In addition, CNC – made sprockets and chains can change the gear ratio, allowing riders to customize the bike’s acceleration and top – speed characteristics according to their riding style.

Racing and Motorsports

In racing, every component of a Ducati motorcycle needs to be optimized for performance. CNC – machined parts are essential. Lightweight titanium valves, carbon fiber fairings, and precision – made engine components are used to shave off milliseconds from lap times. The high – strength and lightweight nature of CNC – made parts help in reducing the overall weight of the bike, which improves acceleration and handling. In MotoGP, Ducati teams rely on custom – designed and CNC – machined parts to gain a competitive edge. For example, the suspension components are carefully tuned and CNC – machined to provide the perfect balance between stiffness and flexibility for different track conditions.

Custom and Vintage Builds

Enthusiasts often use CNC – machining to create custom parts for their Ducati motorcycles or to recreate rare parts for vintage models. In custom builds, CNC – machined parts can be designed to match the owner’s unique style and performance requirements. For vintage Ducati motorcycles, CNC – machining can be used to reproduce hard – to – find parts with the same level of precision as the original components. This allows vintage Ducati owners to restore their bikes to their former glory while also ensuring that the parts are of high quality and durability.