- Demand Analysis & DFM (Design for Manufacturability)

- 3D CAD Design & Simulation

- Mold Material Selection & Cutting

- Rough Machining (Shape the Die Blank)

- Precision Machining (EDM/Wire EDM for Cavities)

- Heat Treatment (Harden the Die)

- Surface Finishing & Die Assembly

- Die Tryout & Optimization

Step 1: Demand Analysis & DFM (The Foundation of a Good Die)

Key Tasks:

- Clarify Part Specifications:

-

- Material (aluminum/zinc/magnesium): Determines die material (e.g., aluminum needs heat-resistant H13 steel).

-

- Tolerance (±0.05mm vs. ±0.1mm): Defines machining precision (tighter tolerances need Wire EDM).

-

- Volume (10k vs. 1M parts): Multi-cavity dies for high volume; single-cavity for low volume.

-

- Critical Features: Undercuts (need slides), thin walls (≥0.8mm for aluminum) that affect cavity design.

- DFM Review (Critical for Cost & Quality):

-

- Optimize part design to simplify the die: Remove unnecessary undercuts (replace with post-machining), add draft angles (1–3° for easy ejection), and ensure uniform wall thickness (avoid >5mm sections to prevent porosity).

-

- Match die size to the die casting machine: Check platen size (die must fit between moving/fixed platens) and maximum clamping force (die weight + injection pressure can’t exceed machine capacity).

Tools & Output:

- Software: SolidWorks, AutoCAD (for part analysis); DFM software (e.g., Sigmetrix) for design validation.

- Output: A DFM report with optimized part design and die feasibility assessment.

Common Mistake:

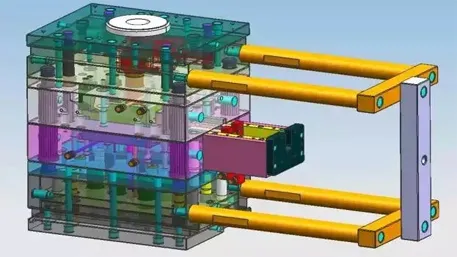

Step 2: 3D CAD Design & Simulation (Digital Prototyping)

Key Tasks:

- Design Die Components:

-

- Cavity: 3D model of the part (add 0.1–0.2mm shrinkage allowance—aluminum shrinks ~1.2% when cooling).

-

- Gating System: Design sprue (main channel), runners (distribute metal), and gates (control flow speed: 5–15 m/s for aluminum). Overflows (1–2x gate size) catch impurities.

-

- Cooling System: Embed water channels (6–10mm diameter) 8–15mm from the cavity—ensure uniform cooling (temperature variation <5°C to avoid warping).

-

- Ejection System: Place ejector pins (3–6mm diameter) in low-stress areas (e.g., part edges) to avoid visible marks.

- Flow Simulation:

-

- Use software like ANSYS Fluent or MAGMAsoft to simulate molten metal filling the cavity:

-

-

- Check for air traps (fix with larger vents: 0.1–0.3mm wide).

-

-

-

- Identify cold shuts (when metal streams don’t merge—increase gate size or flow speed).

-

Tools & Output:

- Software: SolidWorks 3D, AutoCAD Mechanical; Simulation tools (ANSYS, MAGMAsoft).

- Output: A fully annotated 3D die model (with BOM: Bill of Materials) and simulation report.

Critical Check:

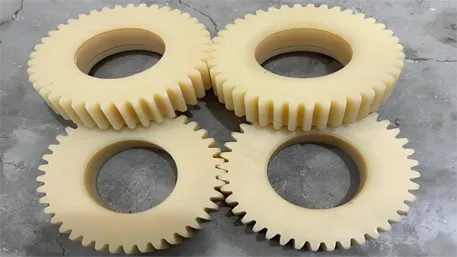

Step 3: Mold Material Selection & Cutting

Material Selection Guide:

|

Die Material

|

Alloy Compatibility

|

Hardness (HRC)

|

Heat Resistance

|

Lifespan (Cycles)

|

Best For

|

|

H13 Tool Steel

|

Aluminum, Magnesium

|

44–48 (after heat treatment)

|

Up to 650°C

|

500k–2M

|

High-volume, high-temperature casting

|

|

P20 Pre-Hardened Steel

|

Zinc

|

28–32 (pre-hardened)

|

Up to 450°C

|

1M–5M

|

Mid-volume zinc casting (cheaper, easier to machine)

|

Material Cutting:

- Process: Use a bandsaw or CNC cutting machine to cut the steel block (die blank) to the required size (e.g., 300x400x200mm for a small die).

- Precision: Cut with ±1mm tolerance—enough for rough machining later.

Common Mistake:

Step 4: Rough Machining (Shape the Die Blank)

Key Tasks:

- Machine Fixed/Moving Die Blanks:

-

- Use a CNC vertical machining center (VMC) (e.g., Haas VF-4) with a 10,000 RPM spindle.

-

- Cut the die’s outer 轮廓 (outline) to match the 3D model, and drill pilot holes for cooling channels (oversized by 1mm for later finishing).

- Mill Gating System Pockets:

-

- Cut slots for the sprue and runners (leave 0.5–1mm 余量 for precision machining).

Tools & Parameters:

- Cutting Tools: Carbide end mills (4–12mm diameter) for steel; coolant (water-soluble oil) to prevent overheating.

- Speeds & Feeds: 150–250 SFM (surface feet per minute) for H13 steel; 250–350 SFM for P20 steel.

Critical Check:

Step 5: Precision Machining (EDM/Wire EDM—The “Heart” of Die Making)

A. EDM (Sinker EDM) for Cavities & Deep Features

- How It Works: Uses an electrode (copper or graphite) to erode the steel via electrical sparks (50–100V, 1–100A). The spark gap (0.01–0.05mm) controls precision.

- Key Tasks:

-

- Machine the cavity: Use a graphite electrode shaped like the part (enlarged by 0.02–0.03mm to account for spark gap).

-

- Cut undercuts: Use a “collapsible electrode” for internal undercuts (e.g., pipe fittings).

- Equipment: Sodick AQ35L, Makino EDNC65.

- Parameters:

-

- Rough EDM: High current (50–100A) for fast material removal (surface finish Ra 12.5–25 μm).

-

- Finish EDM: Low current (1–5A) for precision (Ra 0.8–3.2 μm)—matches the part’s required surface finish.

B. Wire EDM for Thin Walls & Precision Holes

- How It Works: Uses a thin brass wire (0.1–0.3mm diameter) to cut through steel via electrical discharge—ideal for straight edges, thin walls (≥0.5mm), and holes (≥0.2mm diameter).

- Key Tasks:

-

- Cut ejector pin holes (±0.001mm tolerance).

-

- Machine slide components for undercuts (must be parallel to the die’s opening direction).

- Equipment: Fanuc Robocut α-C400iB, Mitsubishi MV2400S.

- Parameters: Wire speed 5–15 m/min; spark gap 0.01–0.02mm.

Critical Check:

Step 6: Heat Treatment (Harden the Die for Durability)

Process for H13 Tool Steel (Most Common):

- Preheat: Heat to 650–750°C for 2–3 hours (reduces thermal shock).

- Austenitizing: Heat to 1020–1050°C for 1–2 hours (converts steel to austenite).

- Quenching: Cool rapidly in oil (100–150°C) to form martensite (hardens the steel to HRC 58–62).

- Tempering: Heat to 520–580°C for 2–4 hours (reduces brittleness while retaining hardness—final HRC 44–48).

-

- Note: Temper twice (double tempering) to eliminate residual stress.

Process for P20 Steel:

- P20 is pre-hardened at the factory (HRC 28–32), so only stress relief annealing is needed: Heat to 550–600°C for 1–2 hours, then cool slowly (prevents warping after machining).

Common Mistake:

Step 7: Surface Finishing & Die Assembly

A. Surface Finishing:

- Polishing:

-

- Use abrasive stones (80–1200 grit) to polish the cavity to Ra 0.8–1.6 μm (smooth surface = no part sticking).

-

- For cosmetic parts (e.g., die cast model cars), polish to Ra 0.2–0.4 μm (mirror finish).

- Deburring:

-

- Remove burrs from EDM cuts (use a CNC deburring machine or manual tools) to avoid damaging the part during ejection.

- Corrosion Protection:

-

- Coat non-cavity surfaces with anti-rust oil (e.g., Mobil Vactra Oil) to prevent oxidation during storage.

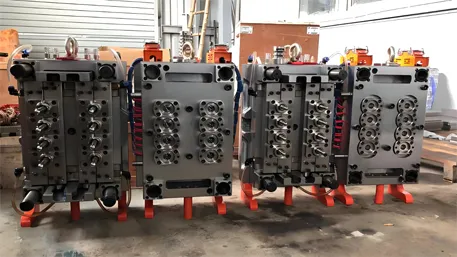

B. Die Assembly:

- Install Components:

-

- Ejection system: Mount ejector pins, plates, and springs (ensure pins move smoothly—no binding).

-

- Cooling system: Install O-rings in cooling channels to prevent water leakage.

-

- Slides (if needed): Attach hydraulic cylinders to slides (align to ±0.01mm to avoid cavity misalignment).

- Align Fixed/Moving Dies:

-

- Use guide pins (4–6mm diameter) to align the two die halves—gap between dies must be <0.01mm (prevents metal flash).

Critical Check:

Step 8: Die Tryout & Optimization (Validate Before Mass Production)

Key Tasks:

- Mount the Die:

-

- Secure the fixed die to the machine’s stationary platen and moving die to the movable platen—use bolts torqued to 50–100 N·m (prevents die movement during injection).

- Set Process Parameters:

-

- Injection temperature: 650–700°C for aluminum; 380–420°C for zinc.

-

- Injection pressure: 5,000–10,000 psi for aluminum; 1,000–3,000 psi for zinc.

-

- Cooling time: 10–30 seconds (part must be solid enough to eject without deformation).

- Produce Test Parts (50–100 Units):

-

- Inspect for defects:

-

-

- Porosity (air bubbles): Widen vents or use vacuum die casting.

-

-

-

- Flash (excess metal): Tighten die clamping force or fix guide pin alignment.

-

-

-

- Warping: Adjust cooling channels (add more near warped areas).

-

-

-

- Undersized parts: Increase cavity size by 0.05–0.1mm (account for shrinkage).

-

Tools & Output:

- Inspection Tools: CMM (for dimensions), X-ray machine (for internal porosity), hardness tester (for part strength).

- Output: Optimized die + validated process parameters (ready for mass production).

Common Mistake:

Key Quality Control (QC) Nodes (Must Not Skip)

- After 3D Design: DFM audit (2+ engineers sign off).

- After Rough Machining: CMM check (±0.2mm tolerance).

- After Precision Machining: CMM cavity measurement (±0.005mm).

- After Heat Treatment: Hardness test (HRC 44–48 for H13).

- After Tryout: X-ray porosity test (<2% porosity for structural parts).

How to Choose a Die Maker (Avoid Low-Quality Dies)

- ISO 9001 Certification: Ensures consistent process control.

- Industry Experience: 5+ years in your niche (e.g., automotive die casting vs. toy die casting).

- Equipment List: In-house EDM/Wire EDM (not outsourced—faster lead times).

- Tryout Capabilities: Owns a die casting machine (can test the die before delivery).

Final Takeaway

- Starting with a DFM-optimized part design.

- Using the right material (H13 for aluminum, P20 for zinc).

- Investing in precision machining (EDM/Wire EDM) and thorough tryout.