Metal 3D printing has evolved into a diverse ecosystem of technologies, each tailored to specific industrial needs—from intricate medical implants to large aerospace components. While all methods build parts layer-by-layer, their approaches to melting, fusing, and shaping metal differ dramatically. This guide breaks down the 4 primary categories of metal 3D printing technologies, their working principles, and ideal applications, helping you navigate the complex landscape of additive manufacturing.

1. Powder Bed Fusion (PBF): High-Precision Metal 3D Printing

Powder Bed Fusion (PBF) is the most widely adopted metal 3D printing category, known for producing dense, high-strength parts with complex geometries. It uses a laser or electron beam to selectively fuse metal powder in a build chamber, layer by layer.

1.1 Selective Laser Melting (SLM): Full Melting for Industrial Strength

- Core Principle: A high-power fiber laser (500–1000W) fully melts metal powder particles (15–45μm) into a homogeneous melt pool, creating fully dense parts (99.5%+ density) .

- Key Parameters:

- Layer thickness: 20–100μm

- Laser energy density: 100–500 J/mm³

- Materials: Titanium alloys (Ti-6Al-4V), stainless steel (316L), aluminum (AlSi10Mg), nickel superalloys (Inconel 718) .

- Advantages:

- Superior mechanical properties (tensile strength comparable to wrought metal)

- Fine surface finish (Ra 6.3–12.5μm) with minimal post-processing

- Applications:

- Aerospace: Lightweight satellite brackets and turbine components

- Medical: Custom titanium implants (hip joints, dental crowns)

- Focus: SLM metal 3D printing process, high-precision metal 3D printing applications.

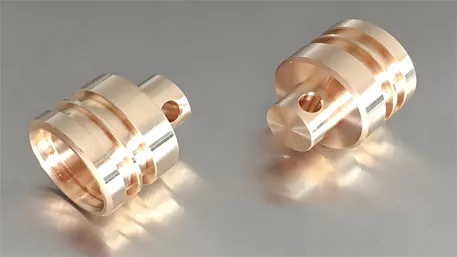

1.2 Direct Metal Laser Sintering (DMLS): Versatile Powder Bonding

- Core Principle: Similar to SLM but sinters powder at temperatures just below melting point, fusing particles without full liquefaction (95–98% density) .

- Key Distinction: Often used interchangeably with SLM in industry due to patent terminology, but DMLS offers broader material flexibility .

- Materials: Tool steels (H13), cobalt-chrome (CoCrMo), copper alloys (CuCrZr) .

- Advantages:

- Faster print speeds than SLM

- Ability to process heat-sensitive alloys

- Applications:

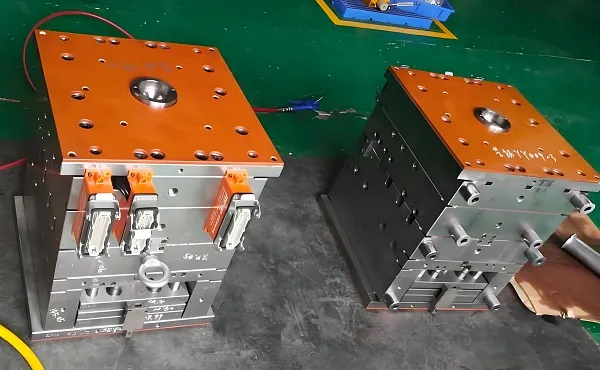

- Automotive: Custom tooling and die inserts

- Jewelry: Intricate metal designs with fine details

- Focus: DMLS vs SLM differences, metal 3D printing for tooling.

1.3 Electron Beam Melting (EBM): High-Temperature Vacuum Processing

- Core Principle: Uses an electron beam (instead of a laser) to melt powder in a vacuum chamber, ideal for oxidation-sensitive metals like titanium .

- Key Parameters:

- Build chamber temperature: Up to 1000°C

- Layer thickness: 50–200μm

- Advantages:

- Reduced residual stress (no post-print heat treatment needed for some alloys)

- Faster build speeds than laser-based PBF

- Applications:

- Large medical implants (spinal cages, bone scaffolds)

- Aerospace: High-temperature engine components

- Focus: EBM metal 3D printing technology, vacuum metal 3D printing.

2. Directed Energy Deposition (DED): Large-Scale & Repair Solutions

Direct Energy Deposition (DED) excels at producing large parts and repairing existing components by depositing molten metal onto a substrate. It uses wire or powder feedstock melted by lasers, electron beams, or arcs.

2.1 Wire Arc Additive Manufacturing (WAAM): High-Speed Large Parts

- Core Principle: An electric arc melts metal wire (e.g., steel, aluminum) which is deposited layer-by-layer, achieving deposition rates up to 15 kg/h (vs. 0.5 kg/h for SLM) .

- Key Advantages:

- Low material cost (wire is cheaper than powder)

- Ability to print parts over 10 feet in size

- Materials: Carbon steel, aluminum alloys (AA6061), nickel alloys .

- Applications:

- Aerospace: Hydrogen storage tanks and aircraft frames

- Marine: Large structural components for ships

- Focus: WAAM metal 3D printing applications, large-scale metal additive manufacturing.

2.2 Laser Engineered Net Shaping (LENS): Precision Cladding & Repair

- Core Principle: A laser melts metal powder injected into the melt pool, enabling precise repair of high-value parts (e.g., turbine blades) .

- Key Capabilities:

- Multi-material printing (e.g., cladding stainless steel onto carbon steel)

- High positional accuracy (±0.05mm)

- Applications:

- Turbine repair for power generation

- Wear-resistant coatings for industrial machinery

- Focus: LENS 3D printing process, metal part repair technology.

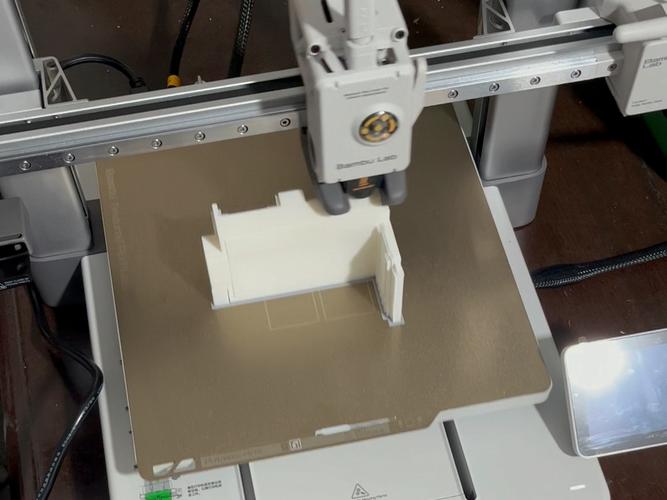

3. Binder Jetting: Cost-Effective Metal 3D Printing

Binder Jetting is a hybrid process that combines additive printing with sintering, offering faster production and lower costs for non-structural parts.

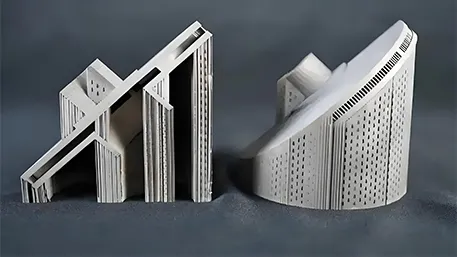

- Core Process:

- A liquid binder is jetted onto a metal powder bed to form a “green part”

- The part is sintered in a furnace to fuse powder particles (final density 96%+) .

- Key Parameters:

- Layer thickness: 50–100μm

- No support structures needed (embedded in powder bed)

- Materials: Stainless steel (316L), bronze, iron-based alloys .

- Advantages:

- Up to 10x faster than SLM for small parts

- Low equipment cost (1/3 of SLM systems)

- Applications:

- Consumer goods: Custom hardware and decorative parts

- Electronics: Heat sinks and sensor housings

- Focus: Binder jetting metal 3D printing, low-cost metal additive manufacturing.

4. Comparison Table: Choosing the Right Metal 3D Printing Type

| Technology | Density | Typical Part Size | Materials | Best For | Cost Level |

|---|---|---|---|---|---|

| SLM | 99.5%+ | Small to medium (<300mm) | Titanium, aluminum, Inconel | High-strength aerospace/medical parts | High |

| DMLS | 95–98% | Small to medium | Tool steels, CoCrMo | Prototyping and tooling | High |

| EBM | 99% | Medium to large | Titanium, refractory metals | Large implants and high-temp parts | Very High |

| WAAM | 98% | Large (>1m) | Steel, aluminum | Structural aerospace/marine parts | Medium |

| Binder Jetting | 96%+ | Small to medium | Stainless steel, bronze | Low-cost mass production | Low |

5. Frequently Asked Questions (FAQs)

Q1: What’s the main difference between SLM and DMLS?

A1: SLM fully melts powder for higher density (99.5%+) and strength, while DMLS sinters powder at lower temperatures for faster speeds and broader material compatibility .

Q2: Can metal 3D printing types be combined for better results?

A2: Yes. For example, DED can be used to add features to SLM-printed parts, combining precision with large-scale production .

Q3: Which metal 3D printing type is best for 3D printing metal jewelry?

A3: DMLS is preferred for jewelry due to its ability to print fine details in gold, silver, and cobalt-chrome alloys .

Q4: Is binder jetting suitable for structural parts?

A4: No. Binder jetting produces parts with lower tensile strength (60–80% of SLM) and is better for non-loaded components .

Conclusion: Matching Technology to Your Needs

The choice of metal 3D printing type depends on your priorities:

- Precision & strength: SLM for aerospace/medical applications

- Speed & cost: Binder jetting for small-batch production

- Large parts: WAAM or EBM for structural components

- Repair/hybrid manufacturing: DED (LENS/WAAM)

As technology advances, hybrid systems combining multiple processes are emerging, blurring the lines between these categories. For personalized recommendations, share your part size, material, and tolerance requirements in the comments!

Stay updated on the latest metal 3D printing innovations by subscribing to our industry newsletter.