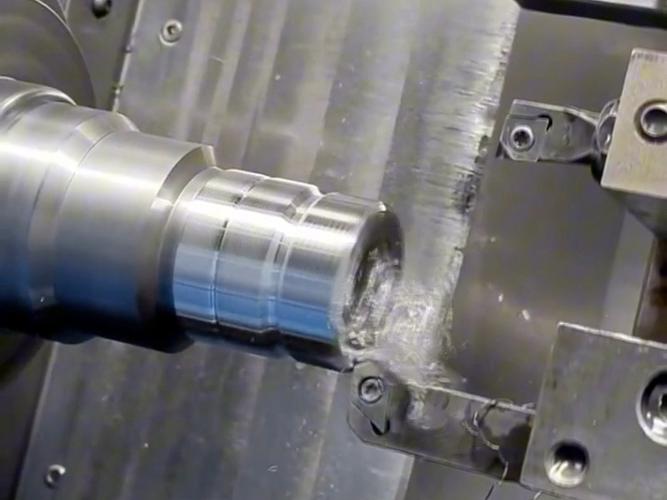

Eccentric turning CNC is like a “Transformer” in the machine tool industry, specialized in processing special-shaped, asymmetric parts. Examples include eccentric shafts of bicycles and eccentric wheels in mechanical watches—these parts have their geometric center offset from their rotation center, appearing “crooked” in shape.

Ordinary lathes can only process symmetric, regular parts, while eccentric turning CNC enables the tool to move precisely around the offset center of the workpiece, gradually shaping the raw material into the desired eccentric form. It is similar to drawing a circle with a compass but intentionally shifting the center. By presetting the eccentric distance and cutting path in the computer program (CNC system), the machine tool can automatically complete complex machining with high precision, producing parts that ordinary lathes cannot.

1. Technical Essence and Mathematical Modeling of Eccentric Turning

(1) Geometric Characteristics and Coordinate Transformation of Eccentric Machining

The key to eccentric turning lies in the fixed eccentric distance (e) between the workpiece’s rotation center and the machine tool spindle’s rotation center. To achieve perfect coordination between the tool’s movement trajectory and the workpiece’s eccentric rotation, a CNC system is essential. This involves the transformation between two coordinate systems: polar coordinates and Cartesian coordinates.

- Denote the spindle rotation angle as θ (ranging from 0° to 360°). Taking the spindle center as the origin, the position of the workpiece’s rotation center can be expressed as (e·cosθ, e·sinθ).

-

- Position in the X-axis direction = workpiece radius R + eccentric distance e × cosθ + radial feed amount of the tool (fᵣ);

-

- Position in the Z-axis direction = axial feed amount of the tool (fₐ).

The angle θ changes in real time with spindle rotation, measured and fed back by the encoder mounted on the spindle.

- Critical note: The eccentric distance e must be smaller than the workpiece radius R (e < R); otherwise, the workpiece will collide with the chuck during rotation. Additionally, the eccentric error caused by workpiece clamping must be controlled within ±0.002 mm, typically adjusted and corrected via fixtures.

(2) Dynamic Compensation Model for Eccentric Errors

- System Error Compensation

Use a laser interferometer to measure spindle runout (radial runout ≤ 3 μm) and feed axis positioning deviation (deviation ≤ 5 μm per 1000 mm). Organize these error data into an error matrix, then input 21 geometric error compensation parameters into the CNC system, including linear errors, angular errors, and perpendicularity errors.

- Random Error Correction

Measure the spindle rotation angle θ in real time at a frequency of over 1000 times per second, and adjust the power output of the X-axis servo motor using the PID algorithm. This offsets errors caused by centrifugal force generated by uneven workpiece mass during rotation, achieving a compensation accuracy of ±0.5 μm.

2. Hardware System Architecture of Eccentric Turning CNC

(1) Technical Parameters and Structural Design of the Spindle Unit

|

Hardware Module

|

Technical Specification Requirements

|

Technical Function

|

|

Electric Spindle

|

Speed adjustable from 50 to 12000 rpm; dynamic balance grade up to G0.4

|

Prevent vibration caused by centrifugal force during high-speed rotation

|

|

Spindle Bearing

|

Paired angular contact ball bearings (Model: 7014AC/P4)

|

Withstand both radial and axial forces; spindle runout ≤ 2 μm

|

|

Spindle Encoder

|

20-bit absolute encoder; angular resolution of 0.001°

|

Real-time measurement of spindle rotation angle, providing accurate data for coordinate calculation

|

|

Dynamic Balancing Device

|

Automatic weight-adjusting type (balance accuracy ≤ 0.1 g·mm)

|

Offset vibration caused by uneven workpiece mass, preventing chatter during machining

|

(2) Precision Assurance Design of the Feed System

- Transmission Mechanism

Adopt high-precision C3-grade ball screws (lead error ≤ 0.003 mm per 300 mm). Apply a preload of 5%–10% of the rated dynamic load during installation to control the backlash of the screw reverse movement within 0.001 mm.

- Servo Drive

Equip both X-axis and Z-axis with servo motors featuring 17-bit incremental encoders (torque ≥ 20 N·m). These motors enable simultaneous control of current, speed, and position, with a response frequency of over 1000 times per second, ensuring tool movement error ≤ 3 μm.

- Guideway System

Use H1-grade linear rolling guideways with low friction (torque ≤ 0.5 N·m). Ensure the straightness error of the tool’s linear movement is ≤ 2 μm per 1000 mm.

3. Core Control Algorithms of the CNC System

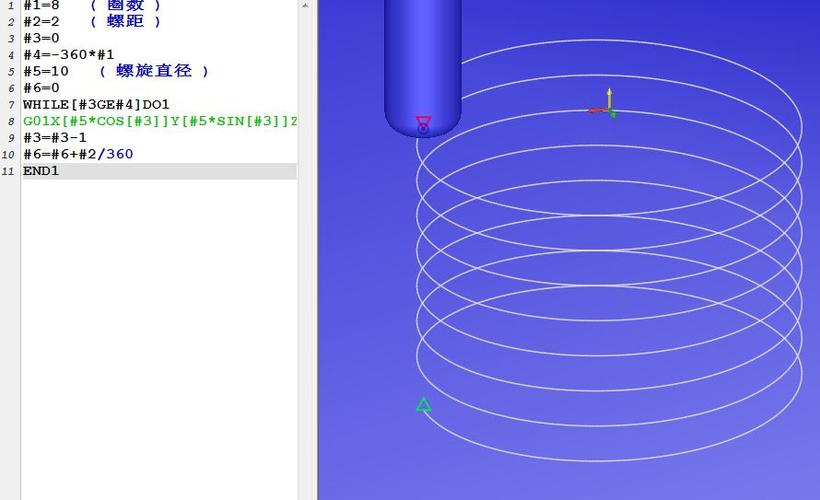

(1) Specialized Interpolation Algorithms for Eccentric Machining

- Spline Interpolation (NURBS)

For workpieces with multi-segment eccentric curved surfaces (e.g., shafts with varying eccentric distances), connect the eccentric segments using 3rd-order NURBS curves to ensure smooth tool transitions. The interpolation calculation time per cycle is < 0.1 ms, and the error between the actual tool path and the theoretical path is ≤ 1 μm.

- Angle-Synchronized Interpolation

Using the spindle rotation angle θ as a reference, express the tool feed amounts of the X-axis and Z-axis as functions of θ: fₓ(θ) = e·sinθ + Δf and f_z(θ) = f_const. This ensures consistent tool feed per spindle revolution, with an error ≤ 0.002 mm/r.

(2) Chatter Suppression Control Strategies

- Force-Feedback Adaptive Control

Install a piezoelectric force sensor (measuring range: 0–5 kN; accuracy: 0.1 N) inside the spindle to monitor cutting force in real time. If the cutting force exceeds 2 kN, the system automatically reduces the tool feed rate by 10%–20%, controlling machining chatter amplitude within 5 μm.

- Modal Damping Optimization

Pre-set vibration parameters for different materials in the CNC system (e.g., natural frequency of aluminum alloy: 200–300 Hz; titanium alloy: 300–400 Hz). Adjust the spindle speed during machining to avoid resonance frequencies, keeping speed fluctuation ≤ 50 rpm.

4. Precision Detection and Calibration Technology

(1) On-Machine Detection Technology Solutions

- Contact Probe Detection

Use a Renishaw OMP40 probe (detection accuracy: ±1 μm) to measure the eccentric distance during machining pauses:

-

- Measurement method: Rotate the spindle by 180°, record the X-axis coordinates at two extreme positions (X₁, X₂);

-

- Eccentric distance calculation: e = |X₁ – X₂|/2; measurement error ≤ 0.001 mm.

- Laser Profile Detection

For complex eccentric curved surfaces (e.g., eccentric arcs), use a laser scanning probe (resolution: 0.5 μm) to scan the workpiece surface, generate point cloud data, and compare it with the design model. The profile error is ≤ 2 μm.

(2) Machine Tool Calibration Process

- Spindle Eccentric Reference Calibration

Use a standard eccentric rod (eccentric distance e = 5 mm; accuracy: ±0.0005 mm) to measure the eccentric distance at different speeds (1000, 3000, 5000 rpm). Plot the curve of speed vs. eccentric error, then input the compensation parameters into the CNC system.

- Feed Axis Synchronization Precision Calibration

Use a ballbar (QC20-W) to detect the circularity error of the X-axis and Z-axis during combined movement (circularity error ≤ 3 μm). Adjust the servo motor gain parameters in the CNC system (position loop gain: 2000–3000 s⁻¹).

5. Typical Process Difficulties and Technical Breakthroughs

(1) Deformation Control of Thin-Walled Eccentric Parts

- Fixture Design

Adopt a hydraulic expansion mandrel (expansion range: 0.02–0.05 mm) with elastic jaws (hardness: HRC30–35) to clamp the workpiece evenly from all sides (clamping force ≤ 500 N). This controls clamping-induced deformation within 1 μm.

- Cutting Parameter Optimization

For thin-walled aluminum alloy parts (wall thickness: 1–2 mm), use high-speed, light-cutting methods:

-

- Cutting speed V = 1500–2000 m/min; feed rate f = 0.05–0.1 mm/r; depth of cut aₚ = 0.1–0.2 mm;

-

- Use PCD inserts (nose radius: 0.2 mm) to reduce cutting heat, keeping the cutting zone temperature ≤ 200°C.

(2) Synchronization Control for Continuous Machining of Multi-Eccentric Segments

- Programming Optimization

Use the G76 eccentric turning cycle command to set multiple eccentric distances (e₁, e₂, …, eₙ) and transition angles α (10°–30°) in the program. This ensures smooth tool transitions between different eccentric segments without sudden speed changes.

- Dynamic Following Error Correction

Enable the “look-ahead control” function in the CNC system (calculating at least 100 tool path segments in advance). Precompute the tool’s acceleration and jerk (acceleration ≤ 5000 mm/s²; jerk ≤ 100000 mm/s³) to ensure the servo motor follows commands without delay.

6. Common Issues with Eccentric Turning CNC

(1) Insufficient Machining Precision

- Deformation Caused by Cutting Force

Material properties (e.g., elastic modulus, Poisson’s ratio) and tool wear lead to uneven cutting forces, causing workpiece deformation. For example, when machining titanium alloy eccentric shafts (eccentric distance: 8 mm; diameter: 50 mm), deformation may reach 8 μm. Use software such as ANSYS/LS-DYNA to simulate cutting forces and thermal deformation, adjust machining parameters to reduce deformation to 3 μm, and control simulation error within 3%.

- Impact of Thermal Deformation

Heat generated by the spindle and feed axes during operation causes thermal expansion/contraction, affecting machining precision. Use an infrared thermometer (resolution: 0.1°C) to monitor temperatures at at least 8 key positions, establish a temperature-error correlation model, and correct thermal deformation in real time with a compensation accuracy of ±1 μm/°C.

(2) Equipment Operation Interference Issues

- Feed Fluctuation Caused by Electromagnetic Interference

Electromagnetic interference from servo motors destabilizes feed axis movement. Use shielded cables with a shielding effectiveness of ≥ 80 dB, ensure grounding resistance ≤ 4 Ω, and add a filter with a cutoff frequency of 100 kHz. This controls errors caused by electromagnetic interference within 0.5 μm.

- Abnormal Dynamic Characteristics of the Machine Tool

Excessive vibration or poor performance of the machine tool affects eccentric turning quality. Conduct regular inspection and maintenance of the machine tool to optimize its performance and ensure stable machining.