|

Advantage

|

Challenge

|

|

Low cutting force (1/5 of aluminum)

|

Risk of melting from frictional heat

|

|

High machinability (fast feed rates)

|

Easy chipping at hole entry/exit

|

|

Transparent finish (no post-polish if done right)

|

Molten chips sticking to hole walls

|

2. Key Technologies for CNC Drilling Acrylic

A. Tool Selection: Sharpness & Low Friction Are Critical

|

Tool Feature

|

Acrylic-Optimized Design

|

Rationale

|

|

Tool Type

|

Single-flute spiral end mill > Double-flute drills > HSS tools

|

Single-flute design reduces contact area (less heat); wide flutes prevent molten chip buildup

|

|

Material

|

Solid carbide (WC-Co) with polished flutes > Uncoated HSS

|

Carbide maintains sharpness longer; polished flutes reduce friction (avoids melting)

|

|

Coating

|

Thin TiAlN (1-2μm) or uncoated (polished 刃口)

|

Thick coatings trap heat; thin TiAlN enhances wear resistance without heat retention

|

|

Point Angle

|

60°-90° (shallow angle) > 118° (metal drill angle)

|

Shallow angles reduce axial force (prevents chipping at hole exit)

|

|

Shank Type

|

Straight shank (φ≤10mm) with precision grinding (runout ≤0.002mm)

|

Low runout avoids uneven cutting (prevents cloudy holes)

|

B. Cutting Parameter Optimization: Avoid Heat Buildup

|

Tool Diameter (d)

|

Spindle Speed (S)

|

Feed Rate (F)

|

Cutting Speed (Vc)

|

Key Rationale

|

|

φ1-3mm

|

8000-12000r/min

|

150-250mm/min

|

25-113m/min

|

High speed minimizes cutting time; moderate feed avoids tool dwell (prevents melting)

|

|

φ3-6mm

|

6000-9000r/min

|

200-300mm/min

|

57-170m/min

|

Balance speed/feed to reduce friction; avoid <5000r/min (causes slow cutting & heat)

|

|

φ6-10mm

|

4000-7000r/min

|

250-350mm/min

|

75-219m/min

|

Lower speed for tool rigidity; higher feed to clear chips quickly

|

C. Cooling & Lubrication: No Liquids—Air-Cooling Is Key

|

Cooling Method

|

Application Scenario

|

Advantages

|

Implementation Tips

|

|

Compressed Air (5-8 bar)

|

All acrylic drilling (especially transparent)

|

No residue; cools chips/tool; clears debris

|

Position air nozzle 3-5mm from cutting zone (aim at tool flute)

|

|

Dry Cutting (No Air)

|

Thick acrylic (>10mm) with low precision

|

Simple setup

|

Reduce speed by 10% to compensate for lack of cooling

|

D. Chip Evacuation: Prevent Molten Buildup

- Peck Drilling (G83): For holes >3×diameter (e.g., φ4mm×15mm), use small peck increments (Q=2-3mm) to eject chips before they melt. Example code:

- Spiral Chip Clearance: Single-flute tools’ helical design lifts chips upward—pair with compressed air to blow chips away from the hole (avoid re-cutting molten debris).

- Post-Peck Pause: Add a 0.1-second dwell (G04 P100) after each peck to let air cool the tool before re-entering.

3. Practical Case: CNC Drilling Transparent Acrylic Sign

Step 1: Process Planning

- Pre-Drilling: Use φ2mm single-flute end mill to drill 1mm-deep pilot holes (reduces chipping at hole entry).

- Final Drilling: φ4mm single-flute carbide end mill (TiAlN-coated) with G83 peck cycle (Q=2mm).

- Deburring: Use φ5mm chamfer mill (15° edge) to drill 0.3mm-deep chamfers (removes sharp edges without scratching).

Step 2: Equipment & Tools

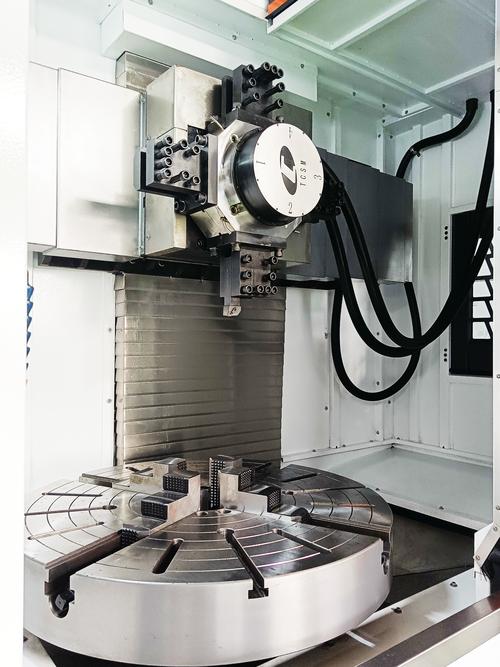

- Machine: Haas TM-1 3-axis milling center (max spindle speed 10,000r/min).

- Tools: T01 (φ2mm single-flute end mill), T02 (φ4mm single-flute end mill, TiAlN), T03 (φ5mm chamfer mill).

- Cooling: 7-bar compressed air (nozzle mounted to spindle).

Step 3: Programming Snippet (FANUC System)

Step 4: Quality Verification

- Chipping Check: Inspect hole edges with a 10× magnifier—no visible chipping (edge smoothness 0.05mm).

- Transparency Test: Hold sheet against light—no clouding or molten residue in holes.

- Surface Roughness: Ra=0.6μm (measured with contactless roughness tester, avoiding scratches).

4. Common Problems & Solutions for CNC Drilling Acrylic

1. Molten Residue on Tool/Hole Walls

- Cause: Low speed (dwell time >0.5s), insufficient air cooling, dull tool.

- Solution:

-

- Increase speed by 20% (e.g., from 6,000r/min to 7,200r/min for φ5mm).

-

- Upgrade air pressure to 8 bar (ensure nozzle is aimed directly at flutes).

-

- Replace tool if 刃口 has visible wear (polished edge becomes dull).

2. Chipping at Hole Entry/Exit

- Cause: No pilot hole, high axial force, tool point angle too steep (118°).

- Solution:

-

- Drill 0.5×d pilot holes (e.g., φ2mm for φ4mm final hole).

-

- Reduce feed rate by 15% (e.g., from 250mm/min to 212.5mm/min).

-

- Switch to 80° point angle tool (reduces force on acrylic edges).

3. Cloudy Holes (Loss of Transparency)

- Cause: Tool runout >0.003mm (uneven cutting), liquid coolant residue, high heat.

- Solution:

-

- Calibrate tool runout (use precision collet; max 0.002mm).

-

- Use only compressed air (no liquids—clean sheet with isopropyl alcohol if needed).

-

- Reduce speed by 10% if hole walls feel warm to the touch.

4. Tool Breakage (Small Diameter <3mm)

- Cause: Excessive speed (>12,000r/min), feed rate too high, workpiece vibration.

- Solution:

-

- Cap speed at 10,000r/min for φ2mm tools.

-

- Lower feed rate to 150-180mm/min.

-

- Use a vacuum chuck (instead of clamps) to secure thin acrylic (<3mm).

5. Q&A: High-Frequency Questions About CNC Drilling Acrylic

Q1: Can I use a standard twist drill for acrylic (instead of single-flute tools)?

- Short Answer: Only for low-precision parts (e.g., non-transparent brackets).

- Limitations: Twist drills have 2 flutes that trap molten chips; 118° point angles cause severe chipping.

- Alternative: If no single-flute tool is available, polish the twist drill’s flutes with 600-grit sandpaper (reduce friction) and use 50% higher speed than metal drilling.

Q2: How to drill deep holes in acrylic (depth >10×diameter, e.g., φ5mm×60mm)?

- Key Steps:

-

- Use a “stepped single-flute tool” (φ3mm→φ4mm→φ5mm) to reduce cutting force.

-

- Peck drill with Q=1.5mm (smaller increments to avoid heat buildup).

-

- Pause 0.2s after each peck (G04 P200) to cool the tool.

-

- Use a long-reach air nozzle (100mm length) to blow chips out of the deep hole.

Q3: How to avoid scratching transparent acrylic during drilling?

- Protective Measures:

-

- Cover the acrylic sheet with low-tack masking tape (remove after drilling—no residue).

-

- Set Z-safe height to ≥10mm (avoids tool dragging on the sheet).

-

- Use a vacuum chuck with a rubber gasket (no metal clamps that scratch edges).