Table of Contents

- What Are Rapid CNC Parts?

- 3 Core Features of Rapid CNC Parts

- Differences Between Rapid CNC Parts and Traditional CNC Parts

- 4 Key Technologies for Achieving “Rapid” Production

- 5 Major Application Areas of Rapid CNC Parts

- 4 Tips for Beginners Choosing Rapid CNC Services

- Frequently Asked Questions (FAQs) for Beginners

1. What Are Rapid CNC Parts?

Rapid CNC Parts (rapid CNC components) are, simply put, “mechanical parts produced quickly using CNC machining technology.”

Their core advantage lies in maintaining basic precision while significantly reducing the time from design to finished product through process optimization and technical improvements. For example, traditional CNC parts may take 15-30 days to deliver, but regular Rapid CNC parts can be ready in 3-7 days. They are ideal for scenarios requiring “fast design verification” or “small-batch emergency replenishment.”

Note: “Rapid” does not mean “low-quality.” Most Rapid CNC parts have a precision of ±0.1mm, which meets the basic needs of daily industrial production and scientific research.

2. 3 Core Features of Rapid CNC Parts

(1) Fast Delivery: Solving the “Can’t Afford to Wait” Problem

This is their most critical advantage. For simple regular parts (e.g., aluminum brackets with holes, small steel shafts), most manufacturers can deliver within 3-7 days. For slightly more complex parts (e.g., multi-step structures with shallow grooves), delivery can still be completed in 10-15 days.

Comparison with traditional CNC: Traditional machining requires scheduling and multiple adjustments, so small-batch parts often take 2-4 weeks. Rapid CNC compresses this time through “priority scheduling” and “simplified processes.”

(2) Small-Batch Friendly: No Forced “Over-Purchasing”

Beginners often face the problem of “needing only 10 parts, but the manufacturer requiring a minimum order of 100.” Rapid CNC solves this pain point perfectly.

It supports “small-batch production”—for example, orders of 1-50 pieces are accepted, and the unit price does not increase significantly (for traditional CNC, small-batch production leads to 2-3 times higher unit prices due to high setup costs).

(3) Qualified Precision: Meeting Basic Needs

Beginners don’t need to worry that “speed means poor precision.” Rapid CNC parts typically achieve the following precision levels:

- Dimensional tolerance: ±0.05-0.1mm (e.g., a part designed to be 50mm long will have a finished length between 49.9mm and 50.1mm);

- Surface roughness: Ra1.6-Ra6.3 (smooth to the touch, with no obvious tool marks);

- Suitable for most non-“high-precision core components” (e.g., machine casings, fixing brackets, experimental samples).

3. Differences Between Rapid CNC Parts and Traditional CNC Parts

Many beginners confuse the two. A side-by-side comparison makes it clearer:

|

Comparison Item

|

Rapid CNC Parts

|

Traditional CNC Parts

|

|

Delivery Cycle

|

3-15 days (regular)

|

15-30 days (regular)

|

|

Batch Adaptability

|

1-50 pieces (focus on small batches)

|

50+ pieces (more cost-effective for large batches)

|

|

Cost Structure

|

Low unit price for small batches; no “minimum order premium”

|

High unit price for small batches; cheaper for large batches

|

|

Process Complexity

|

Simplified processes (e.g., fewer test cuts)

|

Complete processes (multiple test cuts for verification)

|

|

Application Scenarios

|

Prototype verification, emergency replenishment, small-batch production

|

Mass production, high-precision core components

|

4. 4 Key Technologies for Achieving “Rapid” Production

Rapid CNC does not rely on “randomly speeding up”—it achieves speed through technical optimization. Beginners only need to understand these core points:

(1) CAM Automatic Programming: Reducing “Toolpath Programming” Time

Traditional CNC programming may require manual adjustment of each toolpath, taking 2-4 hours. Rapid CNC uses “CAM automatic programming software” (e.g., Mastercam Rapid Edition, Fusion 360 Automatic Mode). After importing a 3D model, the software generates optimized toolpaths in 10-30 minutes and automatically avoids “tool collision” risks.

(2) Stocked Common Materials: No Waiting for “Procurement”

Rapid CNC manufacturers pre-stock “easy-to-machine, high-demand materials” (e.g., 6061 aluminum alloy plates, Q235 steel plates, acrylic sheets). Unlike traditional machining, there’s no need to wait for procurement after receiving an order (procurement usually takes 3-5 days).

For example, if you need to make an aluminum bracket, the manufacturer can take materials from the warehouse and start production the same day.

(3) Standardized Fixtures: Reducing “Workpiece Clamping” Time

Traditional CNC machining of different parts may require redesigning and manufacturing fixtures (taking 1-2 days). Rapid CNC uses “standardized fixtures” (e.g., adjustable vices, universal tooling plates). Most simple parts can be clamped directly, and fixture adjustment takes only 10-30 minutes.

(4) Parallel Processes: “Doing Things Simultaneously” to Save Time

The traditional process is “modeling → programming → machining → inspection,” with each step waiting for the previous one. Rapid CNC uses “parallel processing”—for example, preparing materials and adjusting fixtures while programming, and preparing inspection tools while machining. This compresses the overall time by 30%-50%.

5. 5 Major Application Areas of Rapid CNC Parts

Beginners don’t need to think that Rapid CNC is “only suitable for specific industries.” In fact, it can be used in many scenarios:

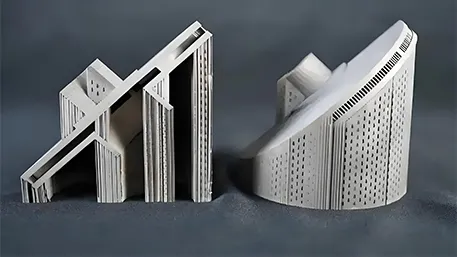

(1) Product Prototype Verification

For example, after designing a new small home appliance casing, 1-5 Rapid CNC prototypes are first made to test if the size fits internal components and if the feel is good. Mass production with molds only starts if there are no issues—this avoids problems after mold opening (mold opening costs are high, and mold modification is troublesome).

(2) Small-Batch Production

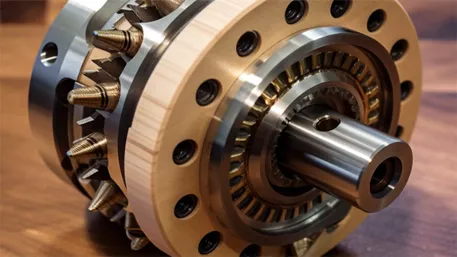

For example, a laboratory may need 10 custom experimental brackets, or a small machinery factory may need 20 spare gear shafts. Rapid CNC enables fast delivery without waiting for large-batch scheduling.

(3) 3C Industry Accessories

Customized accessories for mobile phones and computers (e.g., metal brackets for special interfaces, small heat sinks) often require fast prototyping or small-batch production—Rapid CNC is the mainstream choice.

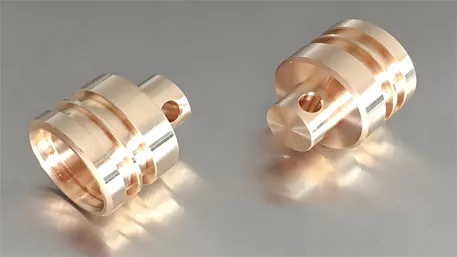

(4) Medical Equipment Parts

Some “small medical devices” (e.g., internal fixing parts for portable detectors, adjustment shafts for rehabilitation equipment) have small demand but require fast delivery. Rapid CNC can meet this need (some manufacturers also process medical-grade materials such as titanium alloy).

(5) Automotive Industry Prototypes

During automotive R&D, a small number of “component prototypes” (e.g., test parts for door locks, fixing brackets for instrument panels) are made. Rapid CNC enables fast production, accelerating the R&D process.

6. 4 Tips for Beginners Choosing Rapid CNC Services

When looking for a manufacturer, beginners should not only focus on “low prices.” These 4 points are more important:

(1) Confirm Delivery Capability: Ask, “Can You Guarantee the Delivery Time?”

Before placing an order, clearly ask: “What’s the fastest delivery time for this part? Is there compensation if delivery is delayed?” Regular manufacturers will provide a clear timeline (e.g., “Within 7 days; 5% of the cost will be deducted for each day of delay”) to avoid “verbal promises but half a month of delay.”

(2) Check Precision Inspection Capability: Ask, “Do You Have Inspection Equipment?”

Precision is critical. Confirm that the manufacturer has basic inspection tools (e.g., calipers, micrometers, coordinate measuring machines) and can provide an “inspection report” (a simple dimensional measurement table is sufficient) to avoid receiving “dimensionally inaccurate parts.”

(3) Verify Material Transparency: Ask, “What Material Will Be Used?”

Don’t just accept “aluminum alloy”—ask for the specific type (e.g., “6061 or 5052”) and request material certification (e.g., a material certificate) from the manufacturer. This avoids “low-quality materials” (e.g., recycled aluminum, which has insufficient strength and is easy to break).

(4) Communication Efficiency: Check, “How Fast Is the Response?”

Beginners may need to modify designs, so the manufacturer should provide quick feedback (e.g., “How long will it take to re-quote and re-produce if I modify a hole position?”). Manufacturers with slow responses will delay your progress.

7. Frequently Asked Questions (FAQs) for Beginners

Q1: Is the precision of Rapid CNC parts sufficient?

A: Sufficient for most scenarios. For example, brackets, casings, and non-core transmission parts fully meet the requirements with ±0.1mm precision. For “core components” (e.g., engine gears, precision bearings), traditional high-precision CNC is recommended instead of Rapid CNC.

Q2: Can small batches (e.g., 1 piece) be produced?

A: Yes. Most Rapid CNC manufacturers support “minimum order of 1 piece.” The unit price will be higher than that for large batches, but much lower than the small-batch unit price of traditional CNC (e.g., a single aluminum part may cost (7 for Rapid CNC, but )14 for traditional CNC).

Q3: If there are small modifications to the design drawing, can the manufacturer adjust quickly?

A: Yes. As long as production hasn’t started, after design modifications, the manufacturer can re-program and adjust toolpaths, usually restarting production within 1-2 days—much faster than traditional CNC (which may take 3-5 days).

Q4: What should I do if there are burrs on the part after receiving it?

A: First, contact the manufacturer. Regular manufacturers will handle it (e.g., “Send it back for free deburring, or refund part of the cost for you to handle it yourself”). Beginners can also handle it simply (gently sand the burrs with sandpaper), but severe burrs (e.g., those affecting assembly) must be resolved by the manufacturer.