A Comprehensive Technical Comparison Focused on CNC Machining Processes

- Machining Difficulty: ★★★★☆ (Difficult)

- Surface Quality: ★★★☆☆ (Medium)

- Machining Efficiency: ★★☆☆☆ (Low)

- Tool Life: ★★☆☆☆ (Short)

- Cost Efficiency: ★★☆☆☆ (Low)

- Machining Difficulty: ★★☆☆☆ (Easy)

- Surface Quality: ★★★★☆ (Good)

- Machining Efficiency: ★★★★☆ (High)

- Tool Life: ★★★★☆ (Long)

- Cost Efficiency: ★★★★★ (Excellent)

2. Cutting Performance Detailed Comparison

- Material Property: Extremely high ductility, good toughness

- Chip Formation: Continuous ribbon chips, difficult to break

- Tool Adhesion: Severe,

- Surface Roughness: Ra 1.6-3.2μm

- Machining Challenges:

-

- Chip entanglement on tools

-

- Surface scratching issues

-

- Dimensional control difficulties

- Material Property: Moderate brittleness, easy to cut

- Chip Formation: Fragmented or spiral chips, easy to break

- Tool Adhesion: Minimal, less built-up edge formation

- Surface Roughness: Ra 0.8-1.6μm

- Machining Advantages:

-

- Easy chip evacuation

-

- Good surface quality

-

- High dimensional accuracy

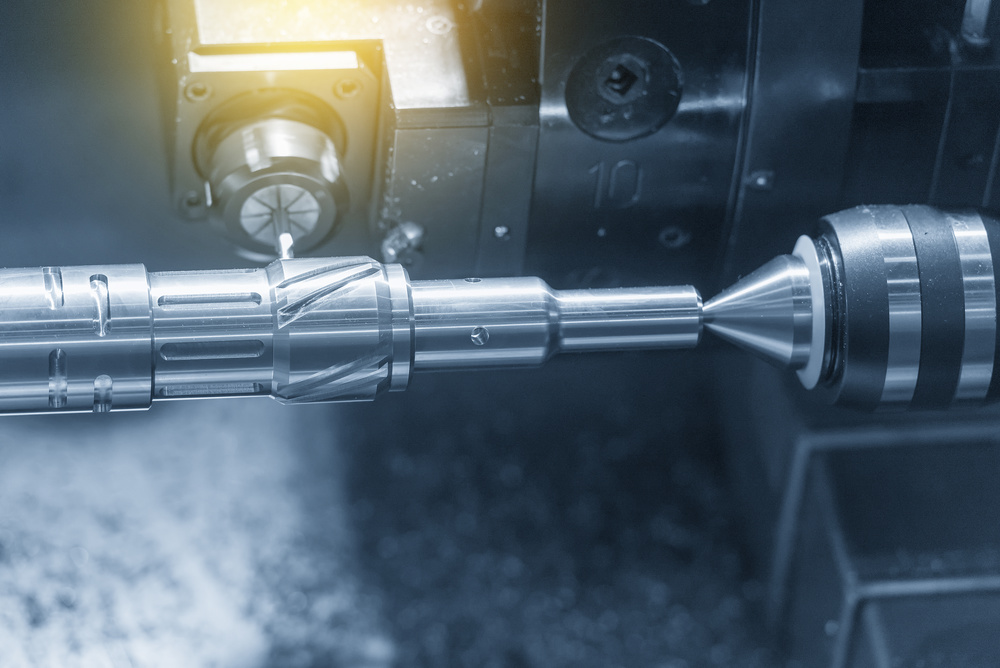

3. Tool Selection and Parameter Settings

Copper Machining Tools

- Preferred: Ultra-fine grain carbide

- Alternative: High-speed steel (HSS-Co)

- Recommended Coating: TiAlN or diamond coating

- Rake Angle: 15°-20° (larger angle reduces cutting force)

- Clearance Angle: 8°-12°

- Edge Angle: 0°-5°

- Tool Nose Radius: 0.4-1.2mm

- Milling Speed: 1000-3000 rpm

- Feed Rate: 100-300 mm/min

- Cutting Depth: ≤5mm (roughing), ≤1mm (finishing)

- Cutting Width: 50-70% of tool diameter

Brass Machining Tools

- Preferred: High-speed steel (HSS)

- Alternative: Regular carbide

- Recommended Coating: TiN coating or uncoated

- Rake Angle: 10°-15°

- Clearance Angle: 6°-10°

- Edge Angle: 0°-3°

- Tool Nose Radius: 0.2-0.8mm

- Milling Speed: 2000-5000 rpm

- Feed Rate: 200-500 mm/min

- Cutting Depth: 10-20mm (roughing), 1-3mm (finishing)

- Cutting Width: 60-80% of tool diameter

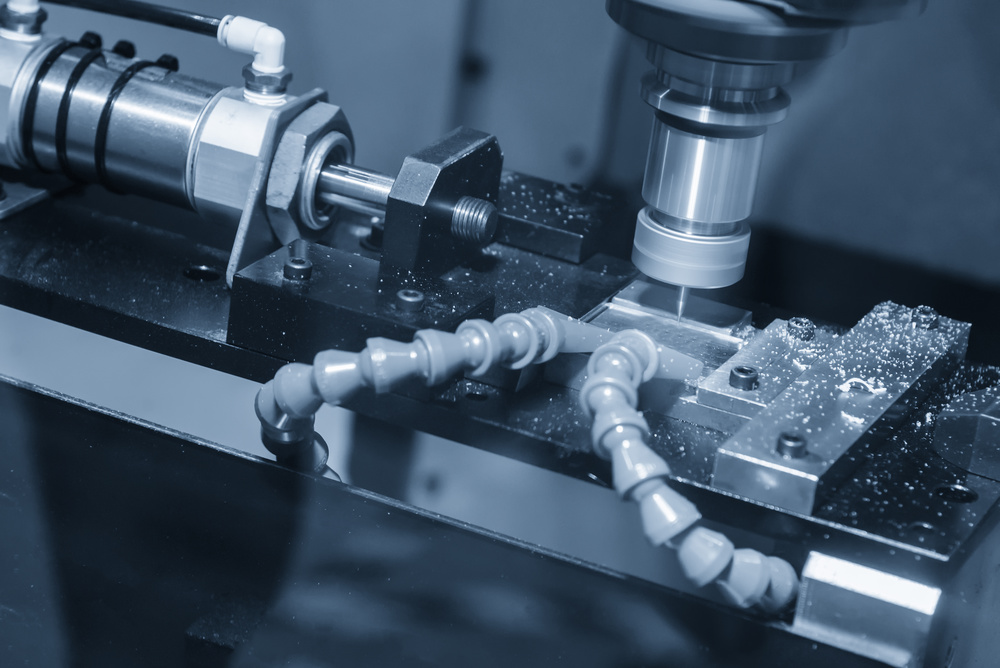

4. Cooling and Lubrication Requirements

Copper Machining Cooling

- Type: Extreme pressure emulsion or synthetic cutting fluid

- Concentration: 8-12%

- Flow Rate: Sufficient for continuous cooling

- Pressure: Medium pressure to avoid splashing

- Use high-pressure cooling system

- Direct cooling to cutting zone

- Maintain clean cutting fluid

- Regular fluid replacement

Brass Machining Cooling

- Type: Emulsion or micro-emulsion

- Concentration: 5-8%

- Flow Rate: Moderate

- Pressure: Low pressure

- Regular cooling system sufficient

- Main function is chip evacuation and lubrication

- Can reduce cooling intensity appropriately

5. Fixture Design and Workpiece Holding

Copper Workpiece Holding

- Clamping Force: Requires high clamping force

- Fixture Material: Use soft jaws or copper fixtures

- Positioning Accuracy: High precision positioning

- Use multiple clamping points

- Avoid workpiece deformation

- Use End face positioning

- Consider vacuum fixtures if possible

Brass Workpiece Holding

- Clamping Force: Medium clamping force sufficient

- Fixture Material: Standard steel fixtures

- Positioning Accuracy: Regular precision

- Standard clamping methods

- Easy to achieve reliable holding

- Can use regular fixtures

6. Machining Process Planning

Copper Machining Process

- Roughing: Low feed rate, small depth of cut

- Semi-finishing: Medium parameters, remove most material

- Finishing: High speed, low feed rate, small depth of cut

- Multiple passes to gradually remove material

- Timely chip removal

- Monitor tool wear carefully

- Control machining temperature

Brass Machining Process

- Roughing: High feed rate, large depth of cut

- Finishing: One pass or minimal passes

- Can use larger cutting parameters

- High machining efficiency

- Long tool life

- Easy to Ensure precision

7. Common Machining Problems and Solutions

Common Copper Machining Problems

- Symptom: Chips adhere to tool and workpiece

- Cause: High material ductility, high cutting temperature

- Solutions:

-

- Use sharp tools

-

- Increase cutting speed

-

- Improve cooling and lubrication

-

- Reduce feed rate

- Symptom: High surface roughness, scratches

- Cause: Chip scratching, tool wear

- Solutions:

-

- Use new tools

-

- Optimize cutting parameters

-

- Improve cooling conditions

-

- Clean chips promptly

- Symptom: Unstable dimensions, out of tolerance

- Cause: Material thermal expansion, tool wear

- Solutions:

-

- Control machining temperature

-

- Measure dimensions frequently

-

- Replace tools timely

-

- Consider thermal expansion compensation

Common Brass Machining Problems

- Symptom: Severe local tool wear

- Cause: Hard particles in material

- Solutions:

-

- Select appropriate tool material

-

- Optimize cutting parameters

-

- Improve cooling conditions

- Symptom: Wavy surface after machining

- Cause: Improper cutting parameters, insufficient rigidity

- Solutions:

-

- Adjust cutting parameters

-

- Increase system rigidity

-

- Use vibration damping measures

8. Quality Control Points

Copper Machining Quality Control

- Dimensional Accuracy: Check every 10-15 minutes

- Surface Quality: Continuous monitoring, detect problems timely

- Tool Condition: Frequent inspection of tool wear

- Chip Condition: Observe chip formation changes

- Use high-precision measuring tools

- Establish quality inspection system

- Record machining parameters and quality data

- Adjust machining process timely

Brass Machining Quality Control

- Dimensional Accuracy: Check every 30-60 minutes

- Surface Quality: Regular inspection sufficient

- Tool Condition: Normal wear, periodic replacement

- Machining Stability: Monitor machining process

- Regular quality inspection

- Standardize machining parameters

- Regular equipment maintenance

- Establish quality records

9. Cost Analysis and Economic Benefits

Copper Machining Cost Structure

- Tool Cost: High (fast tool wear)

- Labor Cost: High (long machining time)

- Equipment Cost: High (high equipment wear)

- Use only when copper is absolutely necessary

- Mainly for high value-added products

- Need to optimize machining process to reduce costs

Brass Machining Cost Structure

- Tool Cost: Low (long tool life)

- Labor Cost: Low (high machining efficiency)

- Equipment Cost: Low (low equipment wear)

- Very high cost performance

- Suitable for mass production

- Significant machining cost advantage

10. CNC Programming Key Points

Copper Machining Programming

- Feed Control: Mainly use G01 linear feed

- Speed Control: Use S code to set appropriate speed

- Cooling Control: M08 continuous cooling

- Safety Considerations: Increase retract distance

- Feed Override: appropriate reduce feed override

- Spindle Override: Can appropriate increase spindle override

- Rapid Traverse: Normal setting

- Tool Compensation: Accurate tool compensation setting

Brass Machining Programming

- Feed Control: Can use higher feed rates

- Speed Control: High speed setting

- Cooling Control: Regular cooling setting

- Machining Efficiency: Optimize tool path for efficiency

- Feed Override: Normal or increased feed override

- Spindle Override: Normal setting

- Rapid Traverse: Normal setting

- Tool Compensation: Regular setting

11. Equipment Maintenance Requirements

Copper Machining Equipment Maintenance

- Spindle System: Frequently check spindle accuracy

- Cooling System: Regular cleaning of cooling system

- Guideway System: Strengthen guideway lubrication and cleaning

- Tool System: Frequently check tool holding system

- Daily Maintenance: Clean equipment, check cooling system

- Weekly Maintenance: Check spindle accuracy, lubricate guideways

- Monthly Maintenance: Comprehensive equipment accuracy check

Brass Machining Equipment Maintenance

- Regular Maintenance: Follow standard maintenance schedule

- Cooling System: Regular inspection and cleaning

- Tool System: Regular inspection

- Accuracy Check: Regular equipment accuracy check

- Daily Maintenance: Regular cleaning and inspection

- Weekly Maintenance: Lubrication and basic inspection

- Monthly Maintenance: Comprehensive maintenance inspection

12. Safety Operation Procedures

Copper Machining Safety Operation

- Chip Hazard: Ribbon chips Easy to get tangled

- Tool Risk: Fast tool wear, Easy chipping

- Temperature Risk: High machining temperature, Easy burns

- Personal Protection: Wear safety glasses, gloves

- Equipment Protection: Ensure safety guards are intact

- Operation Standards: Strictly follow operation procedures

- Emergency Stop: Familiarize with emergency stop button location

Brass Machining Safety Operation

- Chip Hazard: Fragmented chips Easy splashing

- High Speed Risk: Safety risks of high-speed machining

- Equipment Risk: Regular machining safety risks

- Personal Protection: Standard protective equipment

- Equipment Protection: Normal safety protection

- Operation Standards: Standard operation procedures

- Environment Control: Maintain clean working environment

CNC Machining Material Selection Decision Tree

Start Material Selection ↓ Need high conductivity? ├─ Yes → Choose Copper └─ No → Continue ↓ Need high strength? ├─ Yes → Choose Brass └─ No → Continue ↓ Cost sensitive? ├─ Yes → Choose Brass └─ No → Continue ↓ High surface quality requirement? ├─ Yes → Choose Brass └─ No → Choose Copper

Quick Reference Table for Machining Parameters

|

Machining Type

|

Material

|

Tool Material

|

Speed (rpm)

|

Feed (mm/min)

|

Depth (mm)

|

|

Rough Milling

|

Copper

|

Carbide

|

1000-2000

|

100-200

|

3-5

|

|

Finish Milling

|

Copper

|

Carbide

|

2000-3000

|

200-300

|

0.5-1

|

|

Rough Milling

|

Brass

|

HSS

|

2000-3000

|

300-400

|

10-15

|

|

Finish Milling

|

Brass

|

HSS

|

3000-5000

|

400-500

|

1-3

|

|

Drilling

|

Copper

|

Carbide

|

800-1500

|

50-100

|

–

|

|

Drilling

|

Brass

|

HSS

|

1500-3000

|

100-200

|

–

|

Frequently Asked Questions (FAQ)

This CNC machining specialized guide will help operators better understand and master the machining characteristics of copper and brass, improving machining efficiency and product quality.