-

PrefaceIn modern manufacturing, CNC milling and metal stamping stand as two core processing technologies, each possessing unique technical characteristics and application advantages. As manufacturing evolves toward higher precision, efficiency, and lower costs, selecting the appropriate processing technology has become a critical factor for enterprises to enhance competitiveness. This report provides a systematic comparative analysis of these two processes from multiple dimensions including processing principles, technological capabilities, economics, material properties, production cycles, and precision quality, offering scientific decision-making basis for manufacturing practitioners.

1. Processing Principles and Fundamental Differences

1.1 CNC Milling: Digital Subtractive Manufacturing

CNC milling (Computer Numerical Control Milling) is a precision machining process controlled by computer programs, essentially a material removal subtractive manufacturing process. This technology uses rotating multi-edge cutting tools (mills) to cut materials such as metals, plastics, and wood to produce complex-shaped parts.

- Tool Rotation: The spindle drives the milling cutter at high speeds (up to tens of thousands of RPM)

- Workpiece Fixation: Materials are clamped on the worktable, movable along X, Y, Z axes

- Cutting Motion: Tools cut materials according to programmed paths, removing excess portions

- Digital Control: Precisely controls tool path, speed, and feed rate through G-code

1.2 Metal Stamping: Die Forming Manufacturing

- Die Action: Uses pre-manufactured die cavities

- Pressure Forming: Applies enormous pressure to force plastic deformation of metal sheets

- Batch Replication: One-time die manufacturing enables rapid production of numerous identical parts

- Multi-process Combination: Typically includes punching, blanking, bending, drawing and other processes

1.3 Comparison of Fundamental Differences

|

Comparison Dimension

|

CNC Milling

|

Metal Stamping

|

|

Processing Principle

|

Material removal (subtractive manufacturing)

|

Material forming (plastic deformation)

|

|

Processing Method

|

Discrete processing, point-by-point cutting

|

Integral forming, die press forming

|

|

Tool Dependence

|

Universal tools, quick changeable

|

Special dies, long manufacturing cycle

|

|

Processing Process

|

Tool movement, workpiece fixed or moving

|

Workpiece fixed, die movement and pressure application

|

|

Material State

|

Material is cut and removed

|

Material undergoes plastic deformation

|

2. Technological Capabilities and Design Freedom

2.1 Technological Capabilities of CNC Milling

- Complex 3D Machining: Can process very complex 3D geometries, free surfaces, internal cavities, deep grooves, and fine features

- Integrated Machining: Can integrally mill structures that would otherwise require multiple assembled parts from a single blank

- Rapid Prototyping: New parts can be processed by modifying CAD models without physical dies

- Multi-material Adaptability: Suitable for metals, plastics, composites and other materials

- Thin-wall Processing Difficulties: Very thin walls are prone to vibration or damage due to cutting forces

- Internal Sharp Corner Limitations: Limited by tool geometry, cannot process true internal sharp corners (tools have rounded corners)

- Deep Cavity Processing Challenges: Deep cavity processing requires special tools and processes, with lower efficiency

- Standard precision: ±0.01mm

- High-precision processing: ±0.001mm

- Surface roughness: Ra0.8-Ra3.2μm

2.2 Technological Capabilities of Metal Stamping

- Thin-wall Part Manufacturing: Specialized for producing sheet metal parts, can efficiently manufacture various sheet metal components

- Fine Feature Forming: Features like SIM card tray slots on phone frames can be achieved through precision stamping

- Surface Texture Replication: Die cavities can be etched with patterns to directly press surface effects like leather grain or hairline finishes

- High Production Efficiency: Multiple processes can be completed with a single stamping, with fast production speeds

- Design Geometry Limitations: Difficult to manufacture closed internal cavities, complex 3D geometries, and self-intersecting surfaces

- Draft Angle Requirements: Drawing parts usually require draft angles for mold release

- Material Plasticity Requirements: Materials must have good plastic deformation capabilities

- Die Complexity: Complex shapes require multiple processes and complex die structures

- Ordinary stamping: ±0.1mm

- Precision stamping: ±0.01mm

- Surface roughness: Ra1.6-Ra6.3μm

2.3 Comparative Analysis of Design Freedom

|

Design Element

|

CNC Milling

|

Metal Stamping

|

|

3D Complexity

|

★★★★★

|

★★☆☆☆

|

|

Thin-wall Structure

|

★☆☆☆☆

|

★★★★★

|

|

Internal Cavity Structure

|

★★★★☆

|

★☆☆☆☆

|

|

Surface Texture

|

★★★☆☆

|

★★★★★

|

|

Fine Features

|

★★★★☆

|

★★★★★

|

|

Material Thickness

|

Unlimited

|

0.1-10mm (special up to 25mm)

|

|

Design Changes

|

Fast and flexible

|

Costly, long cycle

|

3. Economics and Cost Structure

3.1 Cost Structure of CNC Milling

- Equipment Depreciation: CNC machine tools have high investment costs, with depreciation accounting for a large proportion

- Labor Costs: Requires professional operators and programmers

- Tool Consumption: Cutting tools are consumables that need regular replacement

- Material Costs: Significant material waste (chips), material utilization rate 60%-80%

- High Unit Cost: Significant material waste, long processing time

- Relatively Low Initial Investment: No need for expensive dies

- Economical for Small Batches: Suitable for prototypes and small-batch production

- Cost Stability: Unit cost does not decrease significantly with increasing quantity

- Ordinary CNC machine tools: Processing cost 30-80 yuan per hour

- High-precision machining centers: Processing cost 80-200 yuan per hour

- Single part processing time: From several minutes to several hours

3.2 Cost Structure of Metal Stamping

- Die Costs: Die design, manufacturing, and debugging costs are very high, accounting for the largest proportion of total costs

- Equipment Depreciation: Stamping equipment has high investment costs

- Material Costs: High material utilization rate (70%-90%), but requires specific 规格 sheet materials

- Labor Costs: High automation level, relatively low labor costs

- Extremely Low Unit Cost: Once dies are completed, each part’s production cycle is measured in seconds

- Extremely High Initial Investment: Die costs can reach hundreds of thousands or even millions of yuan

- Economical for Large Batches: Requires huge production volumes to amortize high die costs

- Significant Cost Reduction: Unit cost decreases significantly with increasing production volume

- Simple dies: Tens of thousands of yuan

- Complex dies: Hundreds of thousands to millions of yuan

- Stamping processing: Several cents to several yuan per piece (for large batches)

3.3 Economic Comparison and Break-even Point Analysis

- Cm: CNC milling unit cost

- Cs: Stamping unit cost (excluding dies)

- Tc: Total die cost

- Q: Production quantity

- CNC milling unit cost: 100 yuan

- Stamping unit cost: 10 yuan

- Die cost: 100,000 yuan

- Small-batch production (<1,000 pieces): CNC milling is more economical

- Medium-batch production (1,000-10,000 pieces): Requires specific analysis considering product lifecycle

- Large-batch production (>10,000 pieces): Stamping process has obvious advantages

4. Material Properties and Effects

4.1 Effects of CNC Milling on Materials

- Basically Maintains Original Properties: Using rolled or forged blanks, basically maintains the original properties of the base material after processing

- Surface Stress State: Cutting process produces certain processing stress on the surface, but the affected depth is shallow

- Microstructure: Minor effect on material microstructure, mainly concentrated in the surface layer

- Relatively Low Utilization Rate: Usually between 60%-80%

- Chip Generation: Produces large amounts of chips that need recycling

- Material Waste: High waste costs for precious materials

- Metal Materials: Aluminum alloys, stainless steel, carbon steel, titanium alloys, copper alloys, etc.

- Non-metal Materials: Plastics, composites, wood, stone, etc.

- Hardness Range: From soft materials to high-hardness materials (below HRC60)

4.2 Effects of Metal Stamping on Materials

- Work Hardening: Stamping process causes work hardening, increasing material strength but reducing plasticity

- Stress State Changes: Residual stresses generated inside the material may affect subsequent processing and use

- Microstructure Changes: Grain deformation, increased dislocation density, material property anisotropy

- Relatively High Utilization Rate: Usually between 70%-90%

- Scrap Types: Mainly produces scrap and skeleton materials, easy to recycle

- Nesting Optimization: Material utilization rate can be further improved through nesting optimization

- Plasticity Requirements: Must have good plastic deformation capabilities

- Common Materials: Low-carbon steel, aluminum alloys, copper alloys, stainless steel, etc.

- Thickness Range: Usually 0.1-10mm, up to 25mm in special cases

- Unsuitable Materials: High-carbon steel, cast iron and other brittle materials

4.3 Comparative Analysis of Material Effects

|

Effect Factor

|

CNC Milling

|

Metal Stamping

|

|

Material Property Changes

|

Basically maintains original properties

|

Work hardening, property changes

|

|

Material Utilization Rate

|

60%-80%

|

70%-90%

|

|

Material Waste

|

Large amount of chips

|

Scrap and skeleton materials

|

|

Material Adaptability

|

Almost all machinable materials

|

Mainly plastic metal materials

|

|

Surface Integrity

|

May have machining marks

|

Surface quality depends on dies

|

|

Subsequent Processing

|

Rarely needed

|

May need annealing to eliminate stress

|

5. Production Cycle and Supply Chain

5.1 Production Cycle Characteristics of CNC Milling

- Rapid Startup: From CAD model to first part may take only a few hours or days

- Short Preparation Time: Mainly includes programming, tool preparation, fixture installation, etc.

- Short Debugging Cycle: Program debugging and first piece confirmation are relatively simple

- Easy Design Changes: Only need to modify CNC programs, no need to remanufacture tools

- Multi-variety Small-batch: Suitable for rapid switching between different product productions

- Emergency Production Capacity: Can quickly respond to urgent order requirements

- Raw Material Requirements: Needs block or bar raw materials

- Tool Supply: Requires stable tool supply chain

- Technical Support: Needs professional programming and operation technical personnel

5.2 Production Cycle Characteristics of Metal Stamping

- Long Die Manufacturing Cycle: Die design, manufacturing, and debugging may take several weeks or even months

- Large Preparation Investment: Requires significant preliminary preparation work and investment

- Complex Process Verification: Requires multiple trial runs and adjustments

- Large-batch Advantages: Once dies are debugged, production stability is high

- Continuous Production Capacity: Can achieve 24-hour continuous production

- Good Quality Consistency: High consistency of mass-produced parts

- Raw Material Requirements: Needs coil or sheet raw materials

- Die Manufacturing: Requires professional die manufacturing suppliers

- Equipment Maintenance: Needs professional stamping equipment maintenance services

5.3 Production Cycle Comparative Analysis

|

Cycle Element

|

CNC Milling

|

Metal Stamping

|

|

Design to Production

|

Few hours to days

|

Few weeks to months

|

|

First Piece Time

|

Short (hour level)

|

Long (week level)

|

|

Mass Production Speed

|

Slow (minutes per piece)

|

Fast (seconds per piece)

|

|

Design Change Response

|

Fast (program modification)

|

Slow (die modification)

|

|

Equipment Utilization Rate

|

Medium

|

High (continuous production)

|

|

Product Switching

|

Fast

|

Slow (requires die change)

|

6. Precision and Surface Quality

6.1 Precision and Surface Quality of CNC Milling

- Dimensional Precision: Standard precision ±0.01mm, high precision up to ±0.001mm

- Geometric Precision: Can ensure accurate forming of complex geometric shapes

- Positional Precision: High relative positional precision between features

- Surface Roughness: Ra0.8-Ra3.2μm, higher finish can be achieved through polishing

- Surface Texture: Regular tool marks, can be reduced through process optimization

- Surface Integrity: Machined surfaces are relatively intact with no obvious deformation

- Tool Precision: Geometric precision and wear status of tools

- Machine Precision: Positioning precision and repeatability of machine tools

- Cutting Parameters: Cutting speed, feed rate, cutting depth, etc.

- Material Properties: Hardness, toughness and other properties of materials

6.2 Precision and Surface Quality of Metal Stamping

- Dimensional Precision: Ordinary stamping ±0.1mm, precision stamping ±0.01mm

- Shape Precision: Shape precision control is difficult due to material springback

- Repeatability Precision: High repeatability precision in mass production

- Surface Roughness: Ra1.6-Ra6.3μm, depending on die surface quality

- Surface Texture: Can replicate any texture on die surfaces

- Surface Integrity: May have stretching marks, scratches and other defects

- Die Precision: Manufacturing precision and surface quality of dies

- Material Springback: Elastic recovery characteristics of materials

- Stamping Parameters: Pressure, speed, temperature and other parameters

- Lubrication Conditions: Lubrication has significant impact on surface quality

6.3 Precision and Surface Quality Comparison

|

Quality Indicator

|

CNC Milling

|

Metal Stamping

|

|

Dimensional Precision

|

±0.001-0.01mm

|

±0.01-0.1mm

|

|

Geometric Precision

|

High

|

Medium

|

|

Surface Roughness

|

Ra0.8-Ra3.2μm

|

Ra1.6-Ra6.3μm

|

|

Surface Texture

|

Tool marks

|

Die-replicated texture

|

|

Shape Consistency

|

High

|

High batch consistency

|

|

Dimensional Stability

|

High

|

More affected by temperature

|

7. Application Fields and Typical Cases

7.1 Main Application Fields of CNC Milling

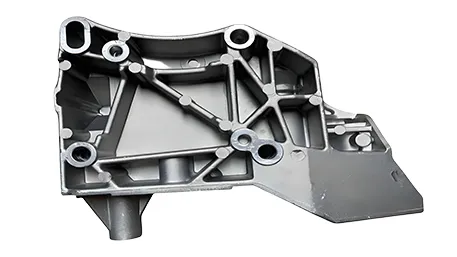

- Engine components

- Complex aircraft structural parts

- Precision instruments and equipment

- Artificial joints and implants

- Precision medical equipment parts

- Surgical instruments

- Prototyping and small-batch production

- Engine blocks and cylinder heads

- Complex transmission system parts

- Precision mold manufacturing

- Connector and interface parts

- Heat dissipation structural parts

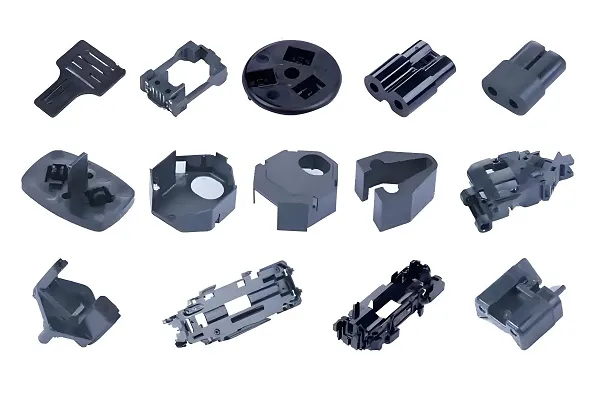

7.2 Main Application Fields of Metal Stamping

- Body panels

- Chassis structural parts

- Radiator and air conditioning components

- Mobile phone frames and housings

- Computer cases and radiators

- Connectors and plugs

- Washing machine and refrigerator housings

- Air conditioning fins

- Small home appliance parts

- Door and window hardware

- Pipes and connectors

- Decorative hardware

7.3 Typical Application Case Analysis

- CNC Solution: Milling from aluminum profiles, suitable for small batches and customization needs

- Stamping Solution: Using precision stamping and drawing processes, suitable for mass production

- Selection Basis: When production exceeds 100,000 pieces, stamping solution is more economical

- CNC Solution: Must use CNC milling, requiring complex 3D machining and high precision

- Stamping Solution: Not applicable, cannot achieve complex internal cavities and curved surfaces

- Selection Basis: Part complexity and precision requirements dictate the use of CNC milling

- CNC Solution: Only suitable for prototyping and small-batch production

- Stamping Solution: Only choice for mass production, high efficiency and low cost

- Selection Basis: Production volume and cost factors determine the use of stamping process

8. Decision Guidance and Best Practices

8.1 Process Selection Decision Flow

- Small-batch production (<1,000 pieces): Priority consideration of CNC milling

- Medium-batch production (1,000-10,000 pieces): Need comprehensive analysis of cost and time factors

- Large-batch production (>10,000 pieces): Priority consideration of metal stamping

- Complex 3D structures: CNC milling is the best choice

- Thin-wall flat structures: Metal stamping has advantages

- Hybrid structures: Consider combined process solutions

- Ultra-high precision requirements (±0.001mm): Must choose CNC milling

- Ordinary precision requirements (±0.01-0.1mm): Both processes can be considered

- Special surface quality requirements: Choose according to specific needs

- Calculate break-even point

- Consider product lifecycle

- Evaluate design change possibilities

8.2 Process Combination Strategies

- First obtain basic shape using stamping

- Then use CNC to machine precision features and complex surfaces

- Suitable for parts with both thin-wall features and precision requirements

- First use CNC to make prototypes to verify design

- After design finalization, make dies for stamping production

- Suitable for new product development and transition to mass production

- Combine 3D printing, casting, CNC, stamping and other processes

- Achieve efficient and low-cost manufacturing of complex parts

- Represents the development trend of modern manufacturing

8.3 Best Practice Recommendations

- Optimize Tool Path: Reduce idle travel and improve processing efficiency

- Choose Tools Appropriately: Select suitable tools according to materials and processing requirements

- Control Cutting Parameters: Balance efficiency and quality, extend tool life

- Strengthen Process Verification: Use simulation software to verify programs and reduce trial cutting time

- Optimize Die Design: Consider material springback and optimize die structure

- Select Appropriate Materials: Choose materials with good plasticity according to product requirements

- Control Stamping Parameters: Reasonably set pressure, speed and other parameters

- Strengthen Die Maintenance: Regularly maintain dies to ensure production stability

9. Development Trends and Future Outlook

9.1 Development Trends of CNC Milling Technology

- Spindle speeds continue to increase, reaching 40,000-60,000 RPM

- Positioning accuracy developing toward nanometer level

- Multi-axis linkage technology becoming increasingly mature

- Adaptive control technology widely applied

- Machine learning optimizing processing parameters

- Predictive maintenance reducing downtime

- Advances in tool materials and coating technology extending tool life

- Optimization of cooling and lubrication technology reducing environmental pollution

- Improvement of chip recycling technology

9.2 Development Trends of Metal Stamping Technology

- Continuous improvement in precision stamping technology accuracy

- Increasing maturity of micro-stamping technology

- Wide application of composite stamping processes

- Popularization of fully automatic production lines

- Robot integration applications

- Development of intelligent inspection technology

- Stamping technology for high-strength steel plates

- Stamping processes for aluminum and magnesium alloys

- Stamping technology for composite materials

9.3 Integrated Development of Both Processes

- Blurring boundaries between CNC milling and metal stamping

- Increasing maturity of hybrid manufacturing technology

- Flexible manufacturing systems integrating multiple processes

- CAD/CAM/CAE integration

- Virtual manufacturing and simulation technology

- Digital twin technology applications

- Promotion of green manufacturing technology

- Establishment of circular economy models

- Achievement of carbon-neutral manufacturing goals

Conclusion

- Fundamental Process Differences: CNC milling is subtractive manufacturing while metal stamping is forming manufacturing, which determines their fundamental differences in processing principles, technological capabilities, and application scenarios.

- Economic Comparison: CNC milling is suitable for small-batch production, metal stamping is suitable for large-batch production, with the break-even point usually between 1,000-10,000 pieces.

- Technical Capability Complementarity: CNC milling excels in complex 3D machining, metal stamping excels in mass production of thin-wall parts, and they can complement each other in many applications.

- Integrated Development Trend: With the development of manufacturing technology, the two processes show an integration trend, forming more flexible and efficient manufacturing solutions.